Cooling and energy-saving device for vehicle heat-generating member

An energy-saving device and heat-generating technology, applied in transmission parts, gear lubrication/cooling, belts/chains/gears, etc., can solve the problems of inability to ensure the working temperature of the transmission, single function, increased cost, etc., to achieve light weight, Good cooling effect and emission reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

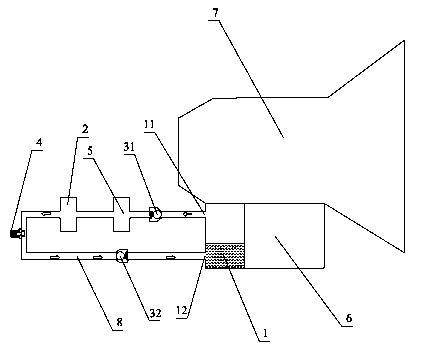

[0027] The cooling and energy-saving device for vehicle heating components involved in this embodiment takes the vehicle transmission as an example, such as figure 1 As shown, its structure includes a container 1 containing a cooling medium, a radiator 2, and the container 1 is closely attached to the transmission lubricating oil tank 6. At the same time, the transmission lubricating oil tank 6 is jointly arranged on the transmission 7. When selecting the boiling point of the cooling medium, refer to the optimal operating temperature of the transmission. For example, the optimal operating temperature of the transmission is about 80 degrees. When selecting the cooling medium, the medium with a boiling point of about 80 degrees can be selected as the cooling medium. The top of the container 1 is provided with a gas outlet 11, and the bottom is provided with a liquid inlet 12. The gas outlet 11 is connected to the inlet of the radiator 2 through a pipeline 8, and the outlet of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com