Construction method of universal type LED (light-emitting diode) lamp bulb and inner flange snap ring type LED lamp bulb

A technology of LED light bulbs and construction methods, which are applied to the parts of lighting devices, cooling/heating devices of lighting devices, lighting devices, etc., can solve the problems of difficult maintenance, many product specifications, and incompatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

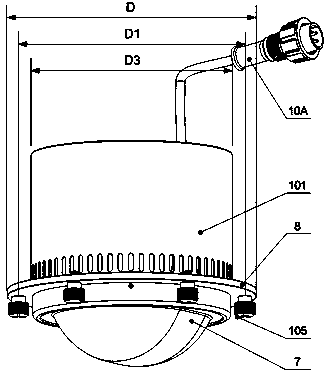

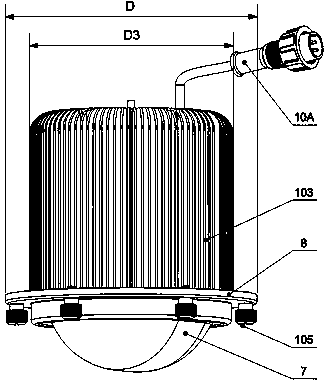

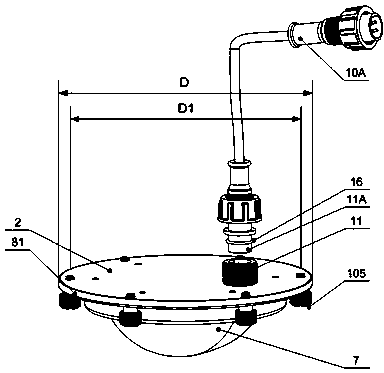

[0060] Example. The construction method of a general-purpose LED light bulb uses a heat-conducting bracket with a flange as the structural support body of the light bulb to form an optical-mechanical core component of the LED bulb, and uses an inner snap ring fixed on the heat-conducting bracket to assist in supporting the optical-mechanical core component of the LED bulb; , and the inner retaining ring is also used as the installation base of the lens retaining ring; the core component of the LED light bulb optical mechanism is composed of a heat-conducting bracket, an optical mechanical module, an inner retaining ring and a light distribution optical lens, wherein the optical mechanical module is equipped with The inner cover and the heat conduction bracket are provided with electrical connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com