Power transformer winding deformation detection method based on vibration analysis

A power transformer and detection method technology, applied in the direction of measuring electrical variables, instruments, measuring electricity, etc., can solve the problems of low diagnostic accuracy of mild and moderate deformation, low sensitivity of mild and moderate deformation, no winding deformation, etc., and achieve operation Simple, easy-to-scale effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to describe the present invention more specifically, the winding fault detection method of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

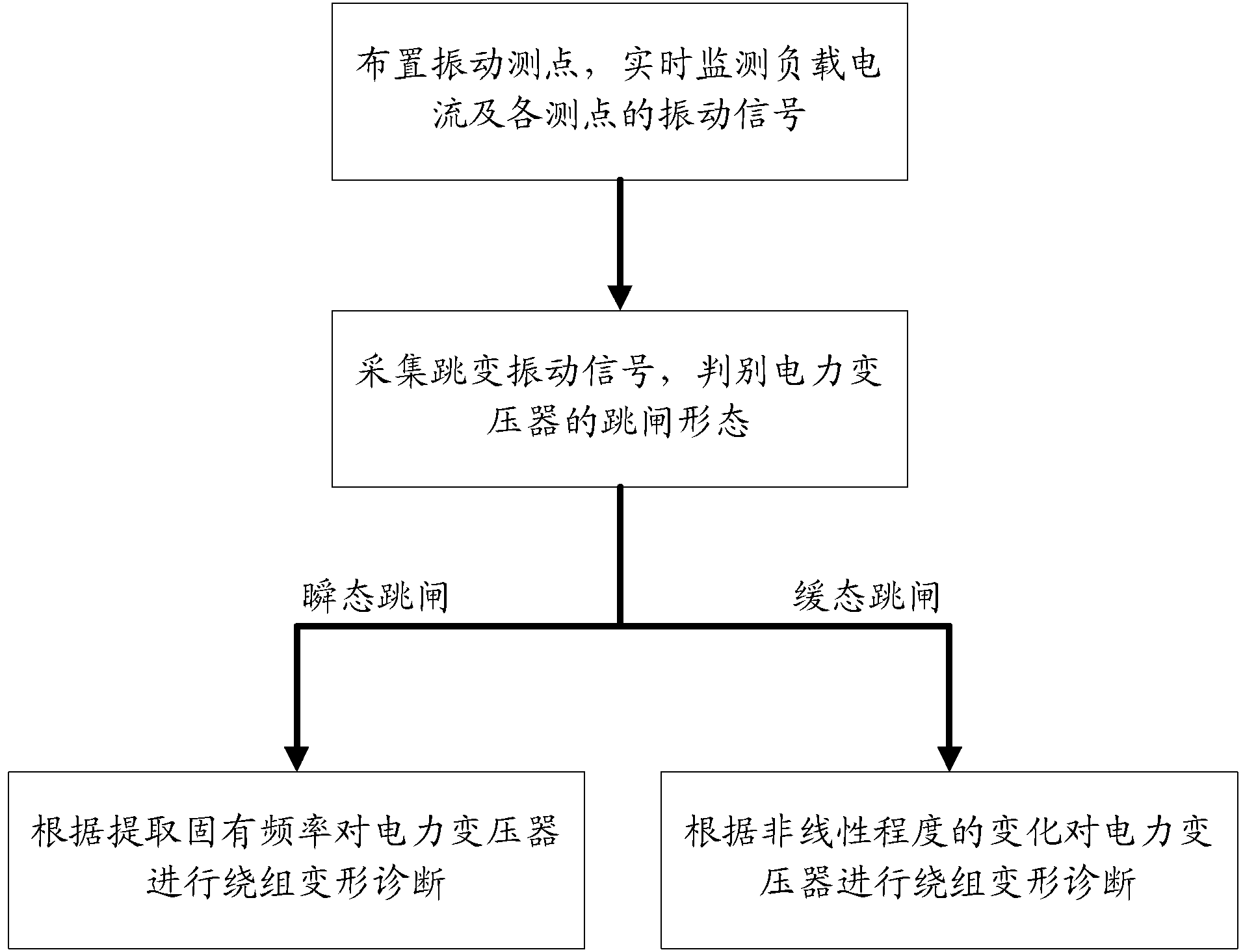

[0039] Such as figure 1 As shown, a method for detecting deformation of power transformer windings based on vibration analysis includes the following steps:

[0040] (1) Arrange vibration measuring points to monitor the load current and vibration signals of each measuring point in real time.

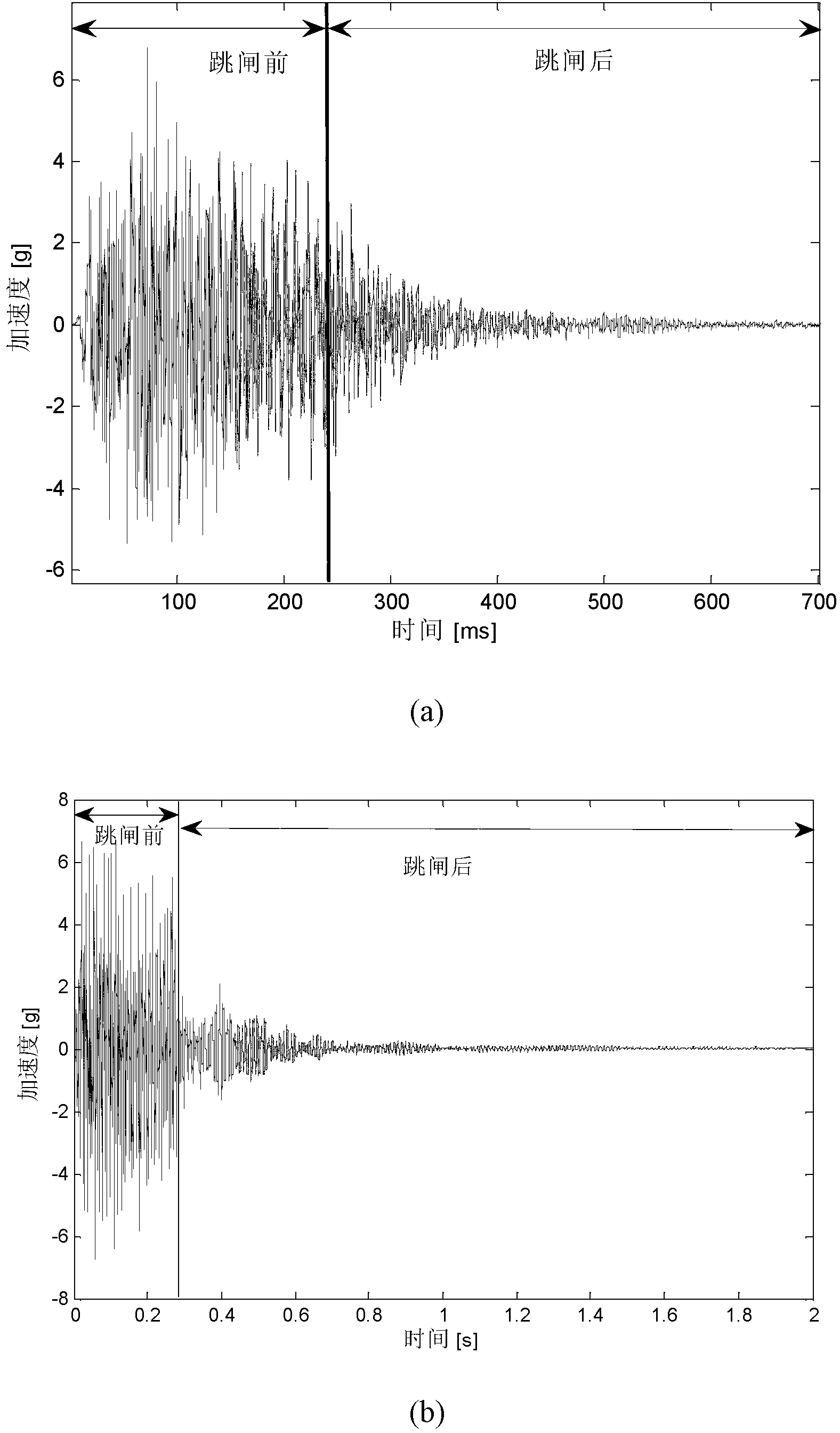

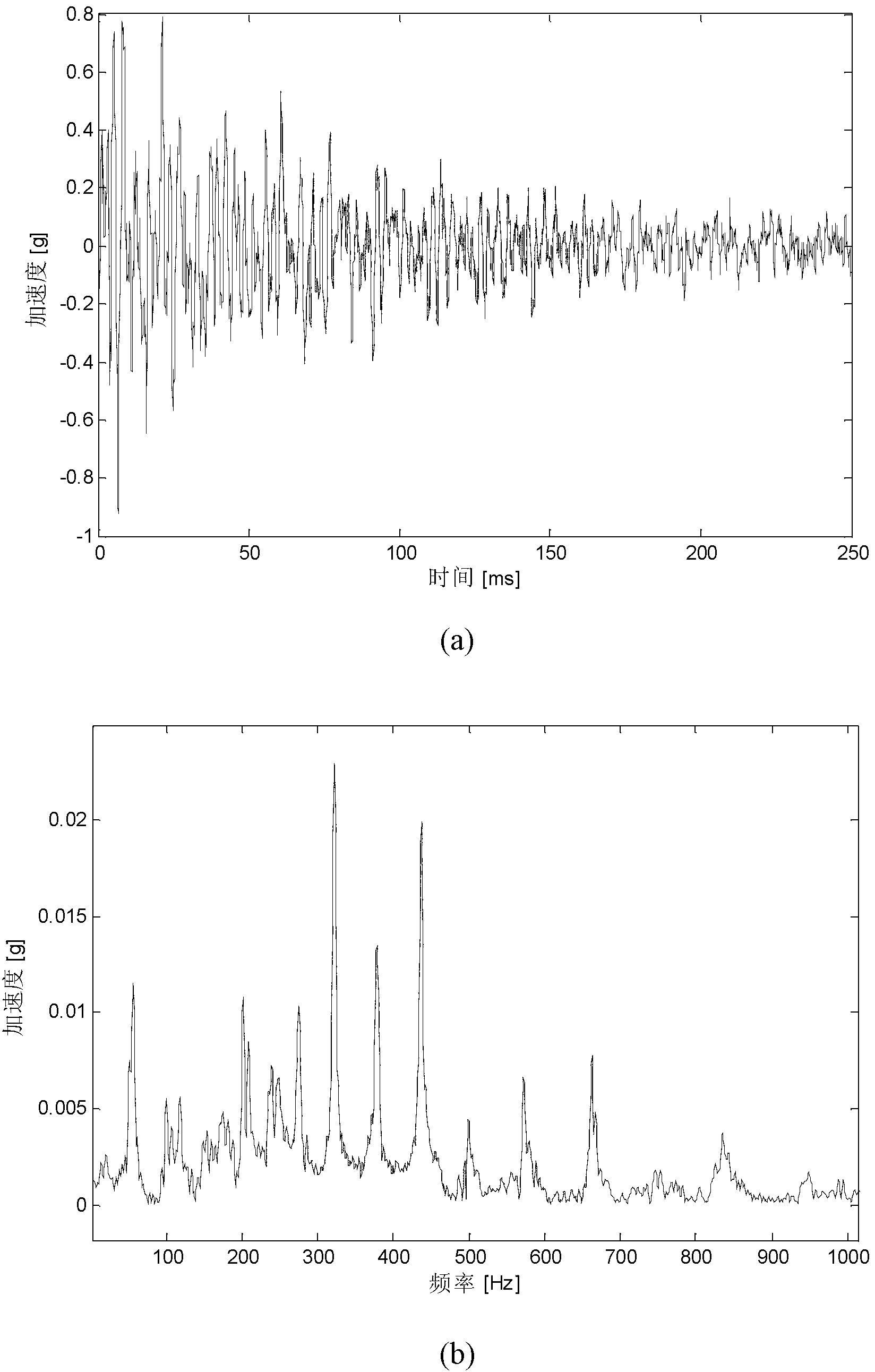

[0041] When a power transformer is running, a short circuit at the output end may occur due to various reasons. When a power transformer is short-circuited at the output end, the short-circuit current is several times the rated working current of the transformer, and the automatic protection device of the transformer will start to trip to make the transformer power off; when the short-circuit occurs, the huge current passing through the transformer windi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com