Method for reducing emission of flue gas pollutants in sintering process

A technology for pollutant discharge and sintering process, applied in the field of iron and steel sintering, can solve the problems of high operating cost, complicated treatment process of sintering flue gas and coking wastewater, and achieve the effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

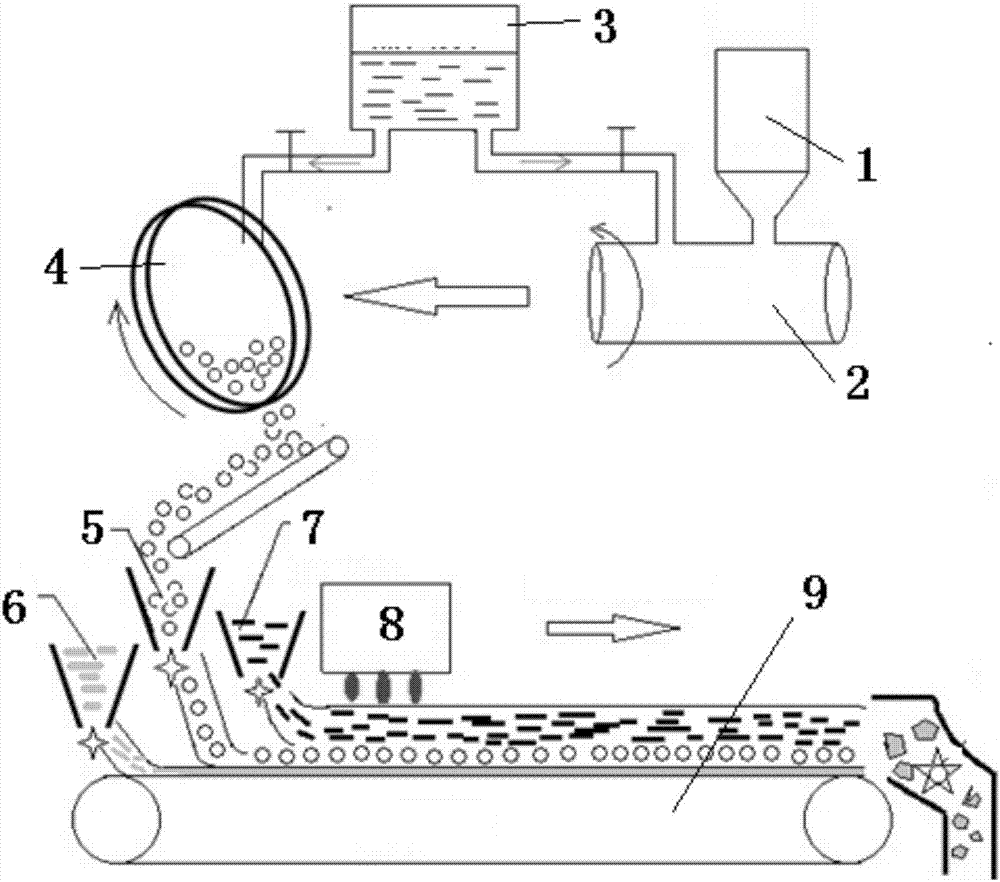

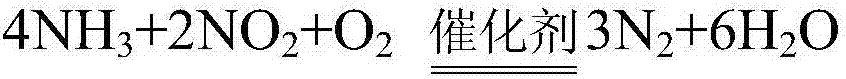

Method used

Image

Examples

Embodiment 1

[0041] Step 1. Measure water and quicklime. The quality of water is 62% of the total mass. Water is added to quicklime for digestion to obtain slaked lime (1), and coking waste water (3) is added to slaked lime (1) for mixing and wetting. The total mass of coking wastewater (3) is 8% of the total mass of coking wastewater and slaked lime. Among them, the main components of coking wastewater are: COD: 2943.27mg / L; BOD: 1170.81mg / L; ammonia nitrogen: 271.82mg / L; TN: 449.19mg / L; volatile phenol: 584.67mg / L; sulfide: 100.13mg / L; Thiocyanide: 259.37mg / L.

[0042] Step 2: Slaked lime (1) and coking wastewater (3) are mixed and wetted, and then pelletized by a disc pelletizer (4) or a drum. During the pelletizing process, continue to add coking wastewater (3) dropwise until the total mass of the added coking wastewater (3) is 15% of the total mass of the coking wastewater and slaked lime, and adjust the pelletizing equipment so that the pellet size of the slaked lime (1) is 3 mm. ...

Embodiment 2

[0053] Step 1. Measure water and quicklime. The quality of water is 70% of the total mass. Add water to quicklime for digestion to obtain slaked lime (1), add coking wastewater (3) to slaked lime (1) for mixed wetting, and coking wastewater (3) The mass is 10% of the total mass of coking wastewater and slaked lime. Among them, the main components of coking wastewater are: COD: 2943.27mg / L; BOD: 1170.81mg / L; ammonia nitrogen: 271.82mg / L; TN: 449.19mg / L; volatile phenol: 584.67mg / L; sulfide: 100.13mg / L; Thiocyanide: 259.37mg / L.

[0054] Step 2: Slaked lime (1) and coking wastewater (3) are mixed and wetted, and then pelletized by a disc pelletizer (4) or a drum. Continue to add coking waste water (3) dropwise during the pelletizing process until the quality of the total coking waste water (3) added is not greater than 18% of the total mass of the coking waste water and slaked lime, and adjust the pelletizing equipment so that the pellet size of the slaked lime (1) reaches 5mm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com