Vacuum process device and vacuum process method

A vacuum processing device, a technology of vacuum processing, applied in transportation and packaging, comprehensive factory control, instruments, etc., can solve problems such as inability to process, inaccessible wafer W2, and handling wafer W2, etc., to achieve handling efficiency or throughput. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0115] Embodiments of the present invention will be described below using the drawings.

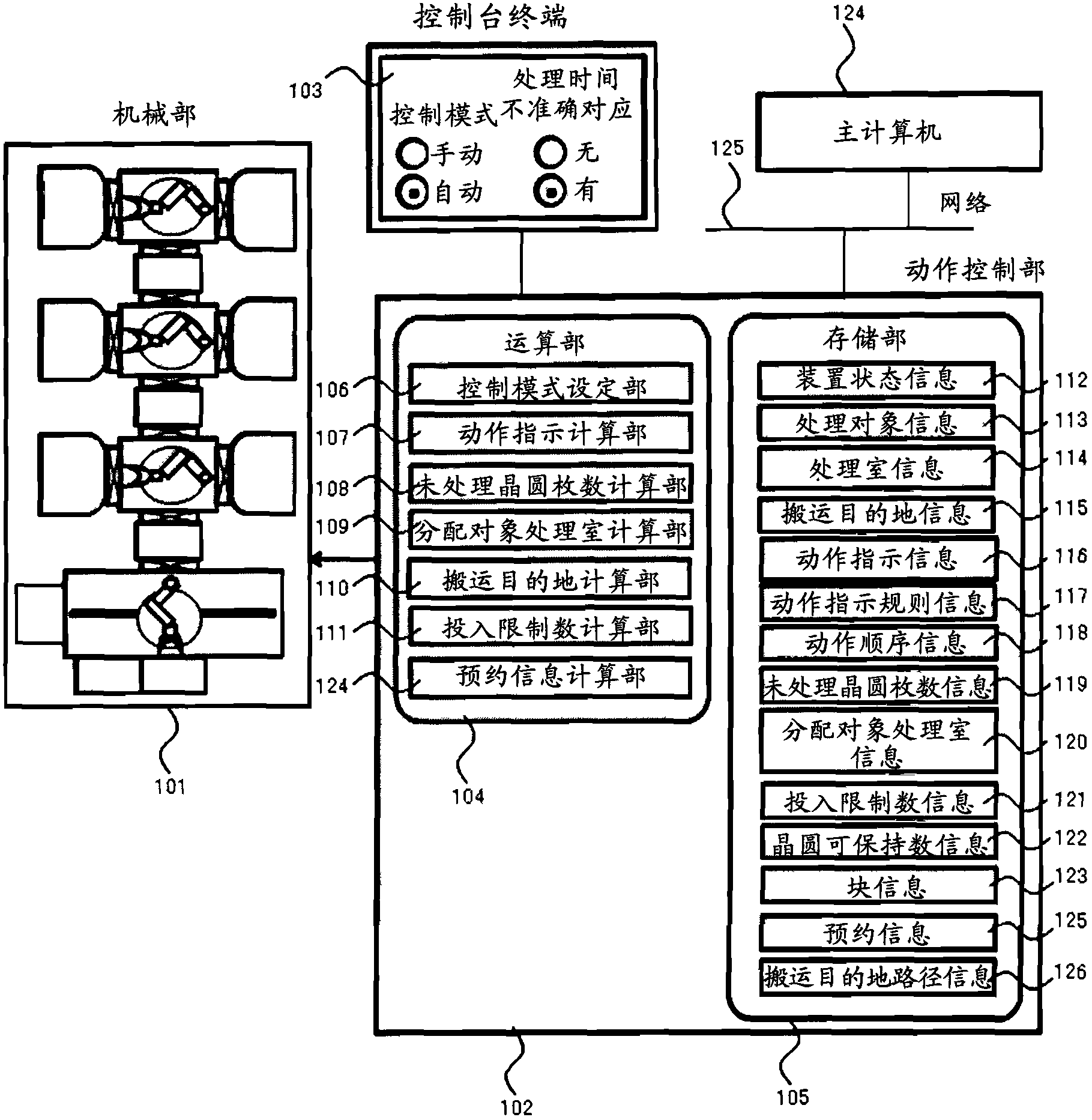

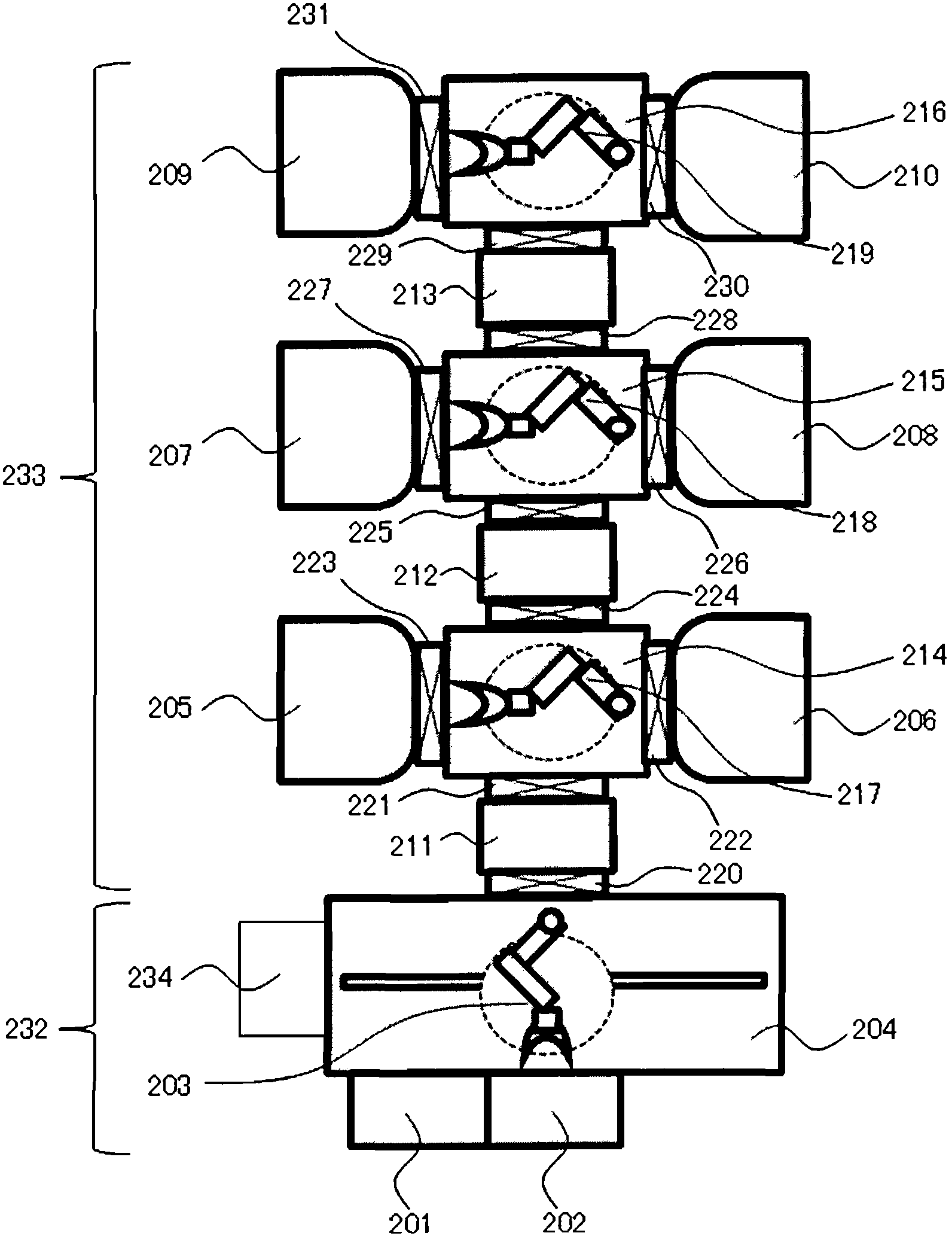

[0116] use figure 1 The outline of the overall configuration of the semiconductor processing apparatus of the present invention will be described. When roughly divided, the semiconductor processing apparatus is composed of a mechanical unit 101 including a processing chamber or a transfer mechanism, an operation control unit 102 , and a console terminal 103 . The mechanical unit 101 is composed of a processing chamber capable of performing processes such as etching and film formation on a wafer, and a transfer mechanism including a robot for transferring the wafer. The operation control unit 102 is a controller that controls the operation of the processing chamber or the transfer mechanism, and is composed of a calculation unit 104 that performs calculation processing and a storage unit 105 that stores various information. In the calculation unit 104, there is a control mode setting uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com