Solar cell component and manufacturing method thereof

A technology of solar cell components and solar cells, which is applied in the direction of electrical components, circuits, photovoltaic power generation, etc., and can solve problems such as short circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

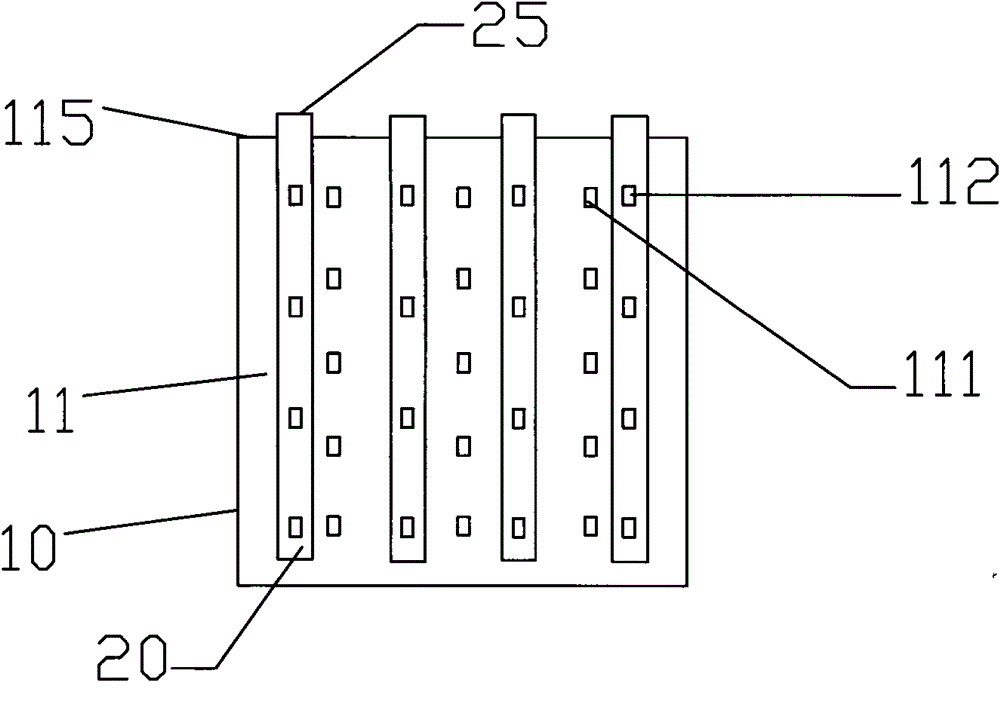

[0046] The solar cell assembly of the present invention will be described in detail below in conjunction with the accompanying drawings by taking Metallization Wrap Through (MWT) back-contact solar cells as an example, but the application of the present invention is not limited to MWT back-contact solar cells, which can also be Other types of back contact solar cells are applied, such as Metallization Wrap Around (MWA) back contact solar cells or emitter wrap through (Emitter Wrap Through, EWT) back contact solar cells.

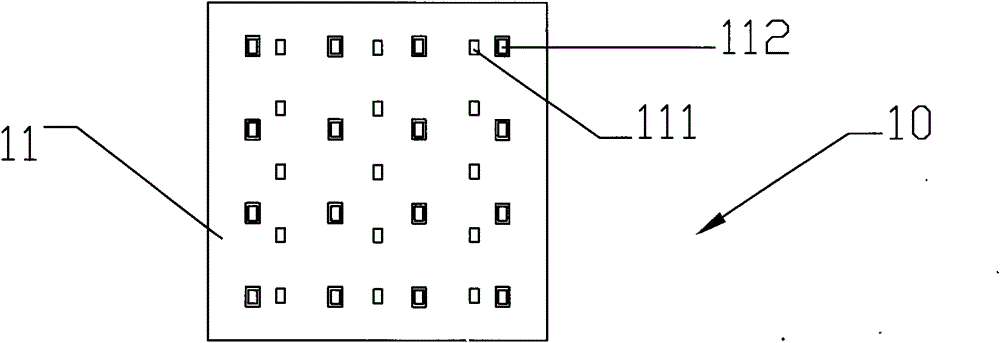

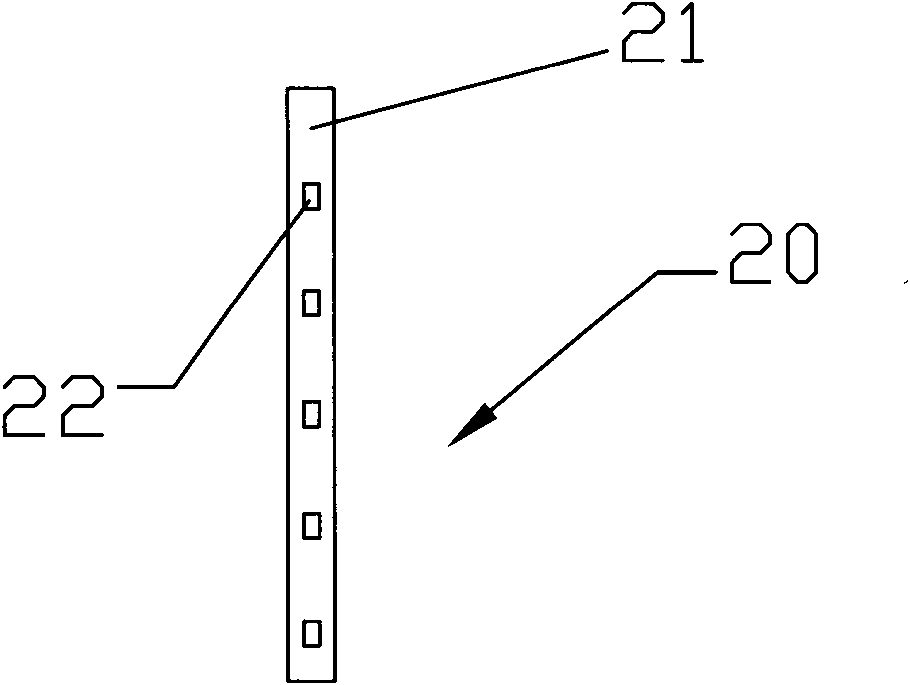

[0047]Solar cell components are used to absorb light energy and convert light energy into electric energy output, which can be a large-area cell component formed by several solar cells connected in series, packaged and arranged in a square array. figure 1 Shown is the back side 11 of a solar cell 10 using metal through (MWT) technology. Solar cells are generally composed of two or more thin semiconductor sheets, and the semiconductor material is usually silic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com