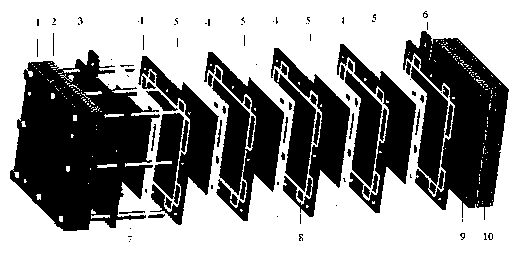

Device for fuel cell electric pile assembly

A fuel cell stack and guide rod technology, which is applied to fuel cell grouping, fuel cells, fuel cell components, etc., can solve the problems of increasing the difficulty and cost of bipolar plate and MEA processing, sealing problems, etc. The effect of easy technology, uniform force and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

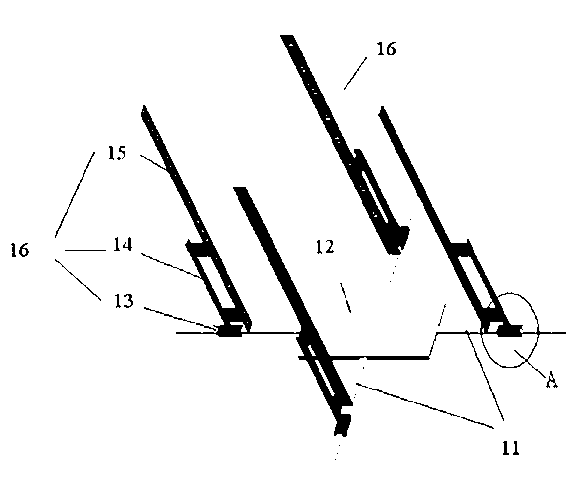

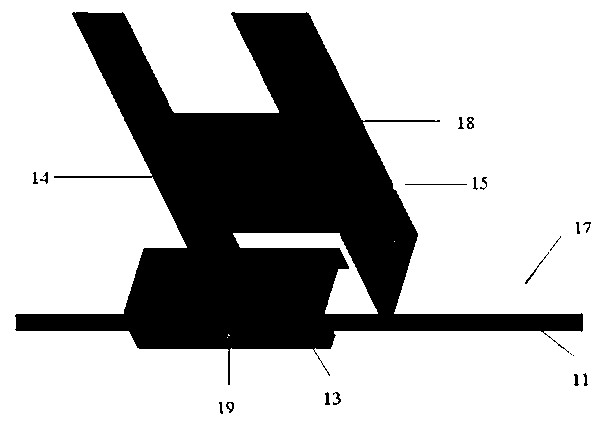

[0029] Such as Figure 2-3 Shown is the fuel cell stack assembly device of the present invention. Four guide rods 11 are arranged on the central axis of the chassis seat 12, and the thickness of the chassis seat 12 and the guide rods 11 are equal and the upper and lower surfaces are horizontal. The upper surface of the guide rod 11 is marked with a guide rod size scale 17 in millimeters or inches. A slider 13 is provided on the guide rod, and there is a threaded positioning hole 19 in the center of both sides of the slider. The slider 13 is fixedly connected with a supporting frame 14 and is perpendicular to each other. The slider can move along the axis direction on the guide rod. , and can be bolted through the threaded positioning hole 19. The vertical rod 15 is connected to the supporting fixture 14 by welding (or sticking), and the vertical rod 15 is perpendicular to the surface of the chassis base 12 . The slide block 13, the supporting fixture 14 and the vertical rod...

Embodiment 2

[0032] Such as Figure 4-5 Shown is another embodiment of the device for assembling fuel cell stacks of the present invention. In this embodiment, the vertical rod 15 is connected and fixed to the supporting and fixing frame 14 by bolts 20 to form a vertical rod assembly, and the vertical rod assembly is fixed by the supporting and fixing frame 14. On the slide block 13 , the slide block can move along the axial direction on the guide rod, and the slide block 13 can be fastened on the guide rod 11 with bolts through the threaded positioning hole 19 . Adjust the overlapping degree between the vertical rod assembly and the supporting fixture, so that the vertical rod 15 is perpendicular to the surface of the chassis base 12 .

[0033] A plurality of guide rods can increase the degree of alignment around the outer periphery of the battery, and setting the vertical rods and the support brackets to be movable and adjustable can reduce processing accuracy and thereby reduce processi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com