Energy-saving motor for hydraulic pump drive

A technology of hydraulic pumps and drive circuits, applied in the direction of connection with control/drive circuits, electrical components, electromechanical devices, etc., can solve problems such as waste of electric energy, easy to burn out, heat loss of motors, etc., to avoid excessive heat generation, protect motors, The effect of protecting energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

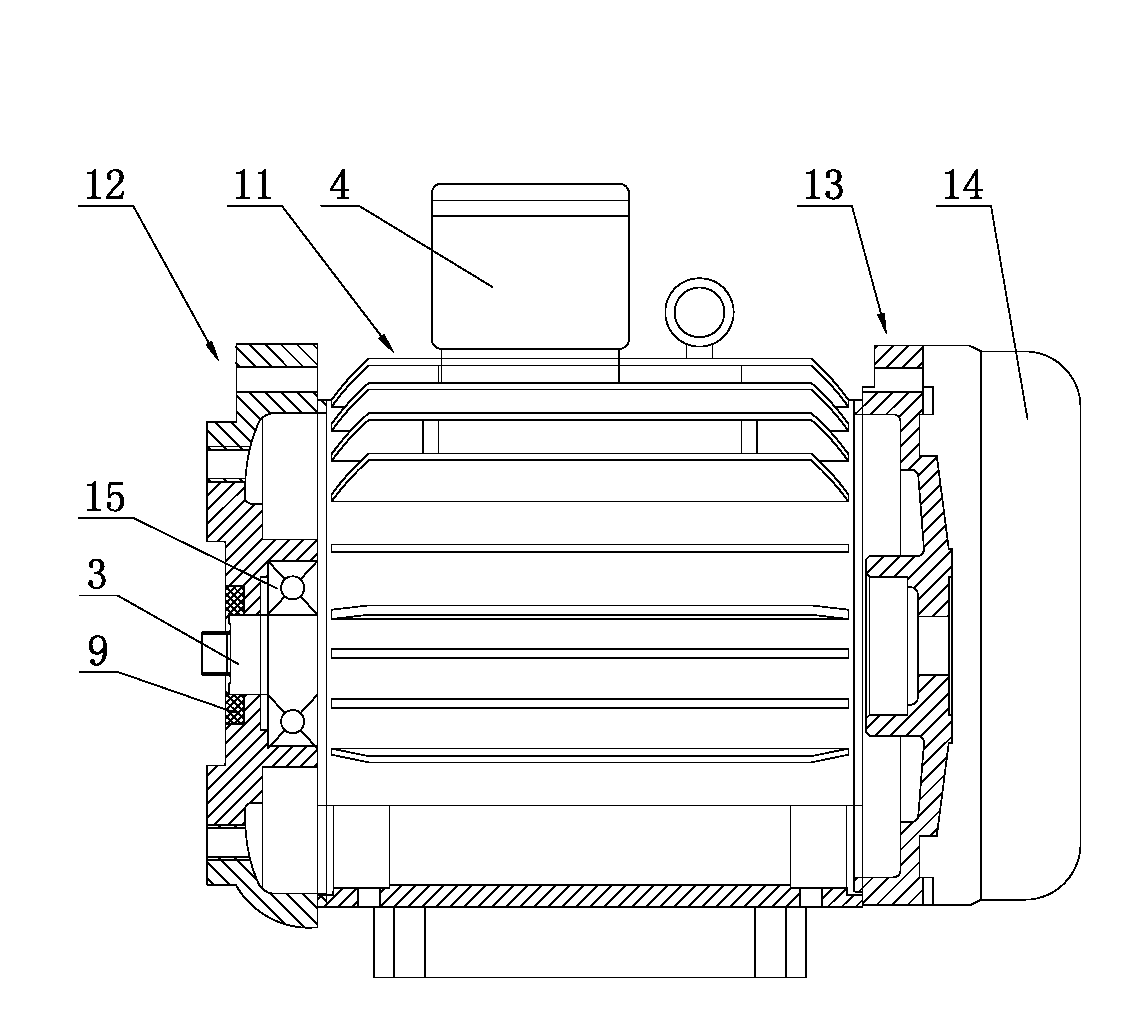

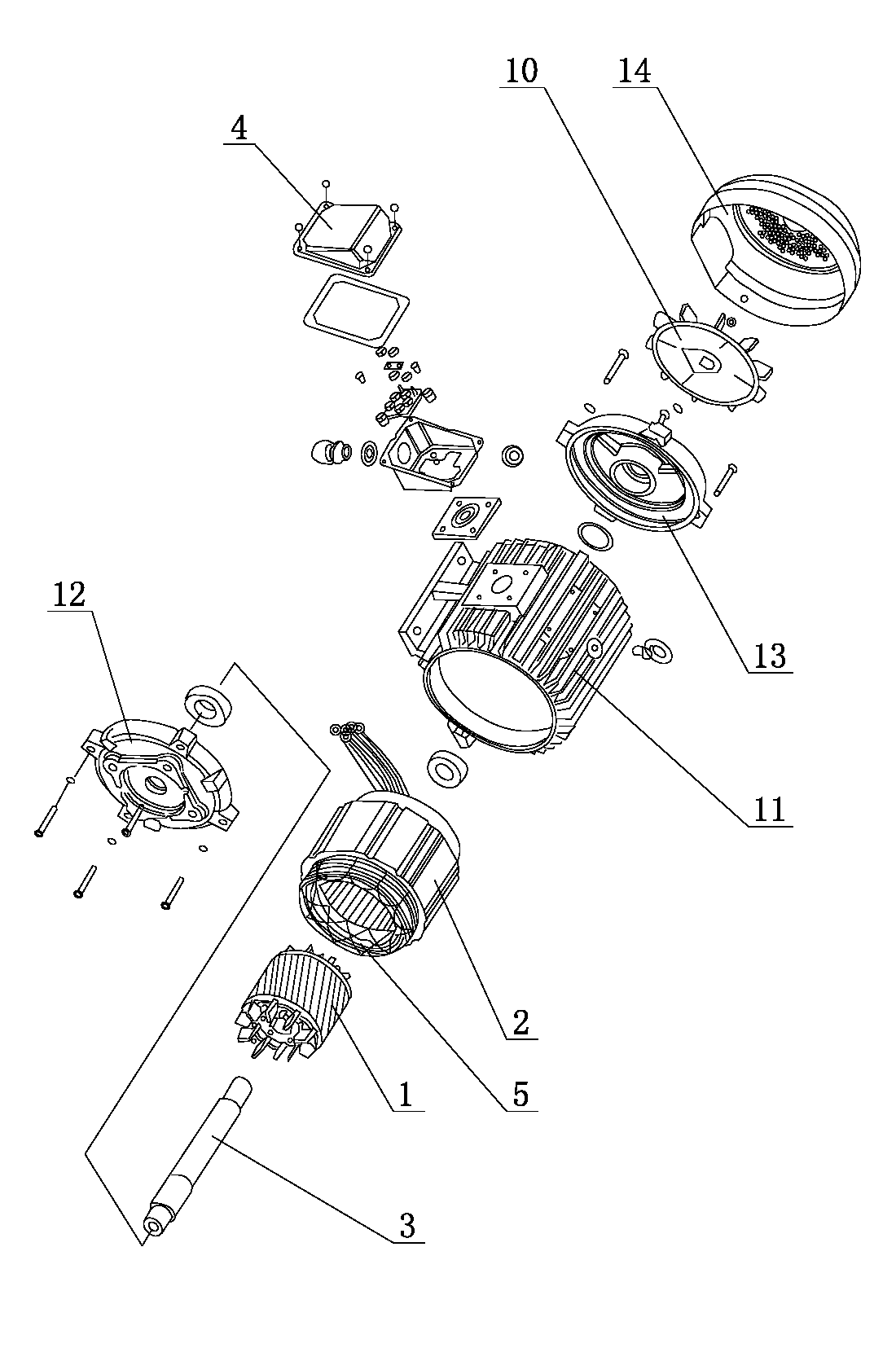

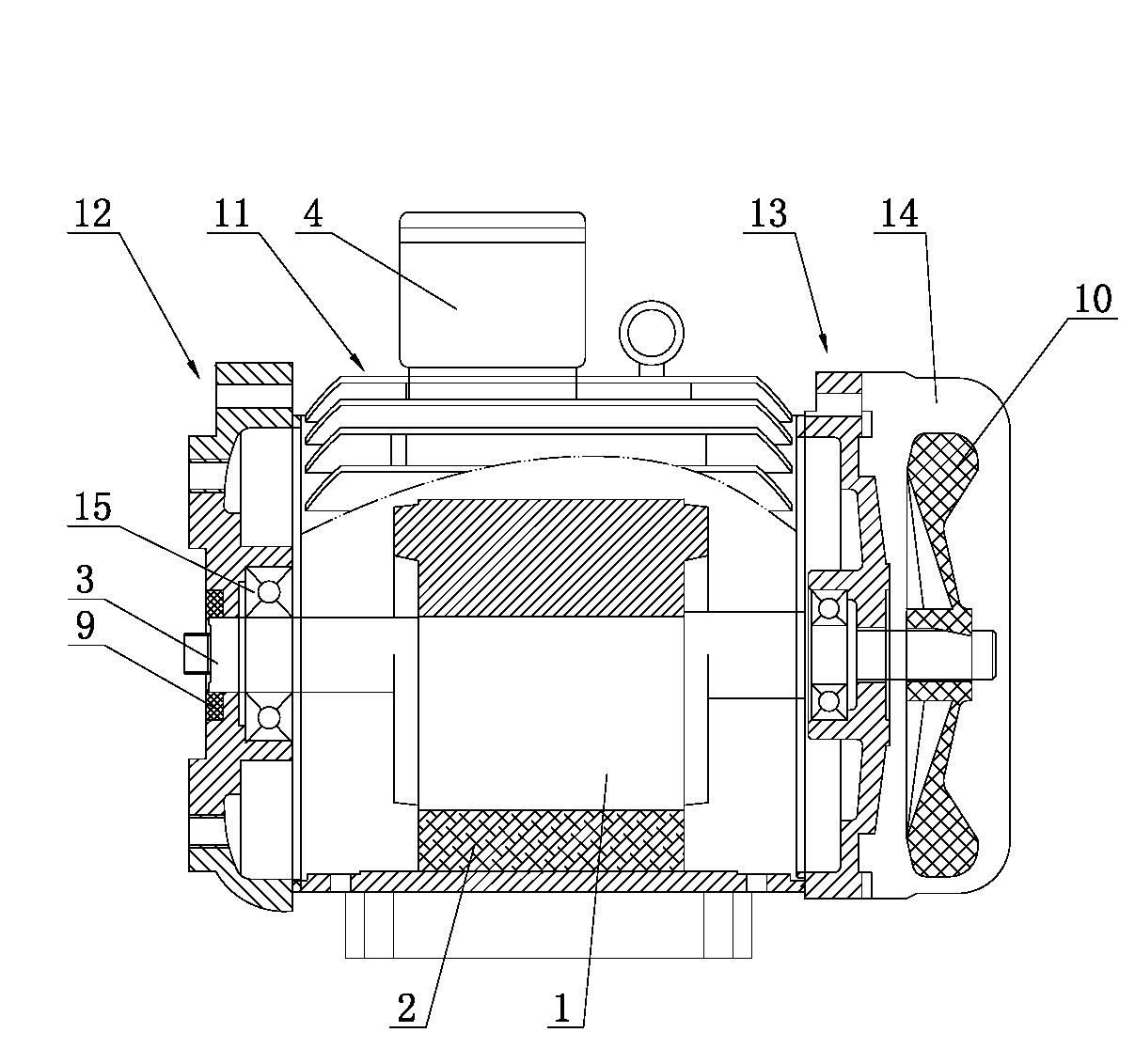

[0019] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

[0020] as attached Figure 1 to Figure 4 As shown, an energy-saving motor for driving a hydraulic pump includes a rotor 1, a stator 2, a rotating shaft 3 and a motor casing, the stator 2 is fixed on the inner wall of the motor casing, the rotating shaft 3 passes through the stator 2, the rotor 1 is located inside the stator 2, and the rotating shaft 3 The two ends of the motor are connected to the motor shell, the motor shell is equipped with a junction box 4, the stator 2 is equipped with a coil winding 5, and the junction box 4 is equipped with a terminal 6, a processor 7, a drive circuit 8 and a drive circuit for detecting The detection device 19 of the output current of the circuit 8 , t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com