Internal combustion engine

A technology for internal combustion engines and burners, which is applied to internal combustion piston engines, combustion engines, mechanical equipment, etc., and can solve problems such as warming up difficult small oxidation catalysts and exhaust treatment devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Preferred embodiments of the present invention will be described in detail below. However, it should be noted that the embodiments of the present invention are not limited to the following aspects, and the present invention includes all modifications and application examples included in the concept of the present invention defined by the claims. The dimensions, materials, shapes, and relative arrangements of components described in the embodiments are not limited to the technical scope of the invention unless otherwise specified.

[0034] In the following description, the upstream side is also referred to as "front", and the downstream side is also referred to as "rear".

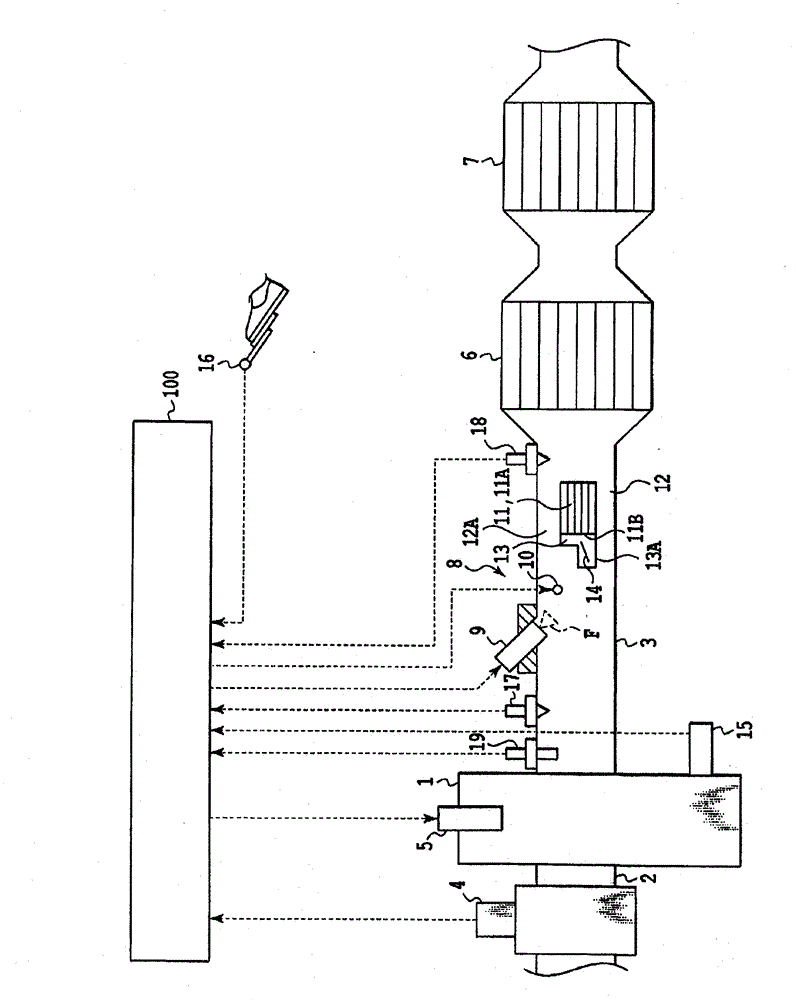

[0035] figure 1 The schematic structure of the internal combustion engine (engine) in this embodiment is shown. The engine is a vehicle-mounted 4-stroke diesel engine. An intake pipe 2 forming an intake passage and an exhaust pipe 3 forming an exhaust passage are connected to the engine body 1 . I...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap