Method for machining circular magnetic steel

A processing method, a ring-shaped technology, which is applied in the field of magnetic steel processing, can solve the problems of product performance, magnetization direction deviation, and deviation, etc., to improve smoothness, reduce angle deviation, and reduce magnetism. Effect of declination error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment one: a kind of processing method of circular magnetic steel, it is characterized in that comprising the following steps:

[0028] (1) Take a magnetic steel billet;

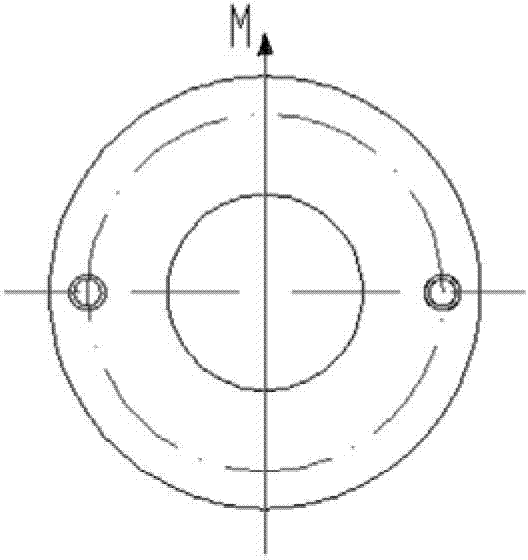

[0029] (2) According to the technical indicators of the circular magnetic steel to be processed, set the machining allowance and the position marks corresponding to the two countersink holes to be processed in the cutting equipment;

[0030] (3) Install the magnetic steel blank in the cutting equipment, cut the magnetic steel blank to obtain a cylindrical magnetic steel with position marks corresponding to the two countersink holes to be processed, the centerline of the two position marks is consistent with the two position marks to be processed The center line of the counterbore is on the same plane;

[0031] (4) Process the inner hole of the cylindrical magnetic steel to obtain a semi-finished circular magnetic steel;

[0032] (5) Fix and install the semi-finished circular magnetic steel in t...

Embodiment 2

[0036] Embodiment 2: This embodiment is basically the same as Embodiment 1, the only difference is that the outer diameter machining allowance of the wire cutting equipment is set to 1 mm, and the depth of the groove is 0.5 mm. Compared with Embodiment 1, the present embodiment In the processing method, the machining allowance is large, the material waste is also large, and the product cost is high.

Embodiment 3

[0037] Embodiment three: a kind of processing method of circular magnetic steel, it is characterized in that comprising the following steps:

[0038] (1) Take a magnetic steel billet;

[0039] (2) According to the technical indicators of the circular magnetic steel to be processed, set the machining allowance and the position marks corresponding to the two countersink holes to be processed in the cutting equipment;

[0040] (3) Install the magnetic steel blank in the cutting equipment, cut the magnetic steel blank to obtain a cylindrical magnetic steel with position marks corresponding to the two countersink holes to be processed, the centerline of the two position marks is consistent with the two position marks to be processed The center line of the counterbore is on the same plane;

[0041] (4) Process the inner hole of the cylindrical magnetic steel to obtain a semi-finished circular magnetic steel;

[0042] (5) Fix and install the semi-finished circular magnetic steel in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com