Novel method for manufacturing wind turbine blade rib plate die

A technology for wind power blades and molds, which is applied in the production field of new super-large wind power blade rib plate molds, can solve the problems of large size of blade molds, high transportation costs, large mold manufacturing space requirements, etc. Uniform, high flatness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

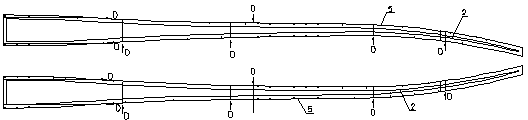

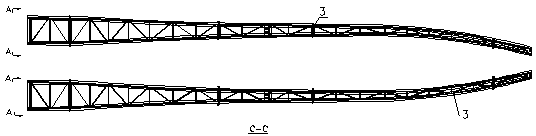

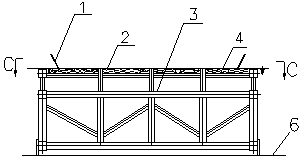

[0014] Embodiment 1: as Figure 1-Figure 4 As shown, the wind turbine blade rib mold according to the embodiment of the present invention is composed of the following parts: bonding angle 1; rib 2; mold steel frame 3; heating layer 4; glass bulb mold 5.

[0015] When making the mold steel frame 3, first complete the production of the mold steel frame 3, and then cut out the outline of the glass shell mold steel plate on both sides according to the size required by the blade rib plate, and weld it with 80X80X4 square steel around the bottom of the panel to enhance its rigidity , to avoid deformation of glass shell mold steel plate. A heating layer 4 and a vacuum tube are laid below the glass bulb mold 5 for heating the heating layer 4 and reaching the top of the glass bulb mold 5 through the vacuum tube to carry out vacuuming operation when the rib plate 2 is made. Then weld the glass bulb mold 5 (including the heating layer) to the corresponding position of the mold steel fra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com