Single tube type vacuum radiating system

A radiator and vacuum technology, applied in the direction of indirect heat exchangers, tubular elements, heat exchange equipment, etc., can solve the problems of high product cost, increased coal consumption, large heat loss, etc., to increase the heat dissipation effect, increase the Heating area and the effect of improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

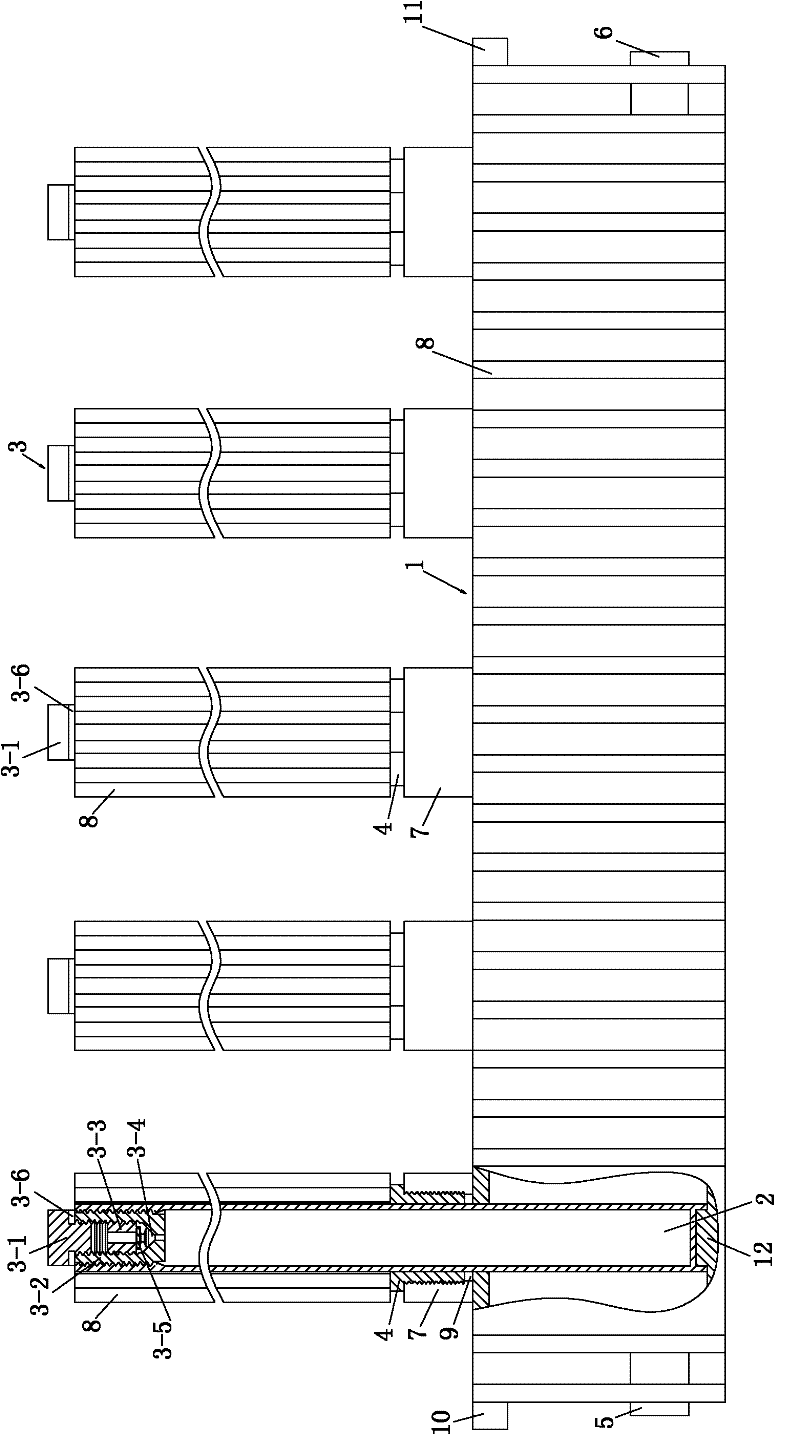

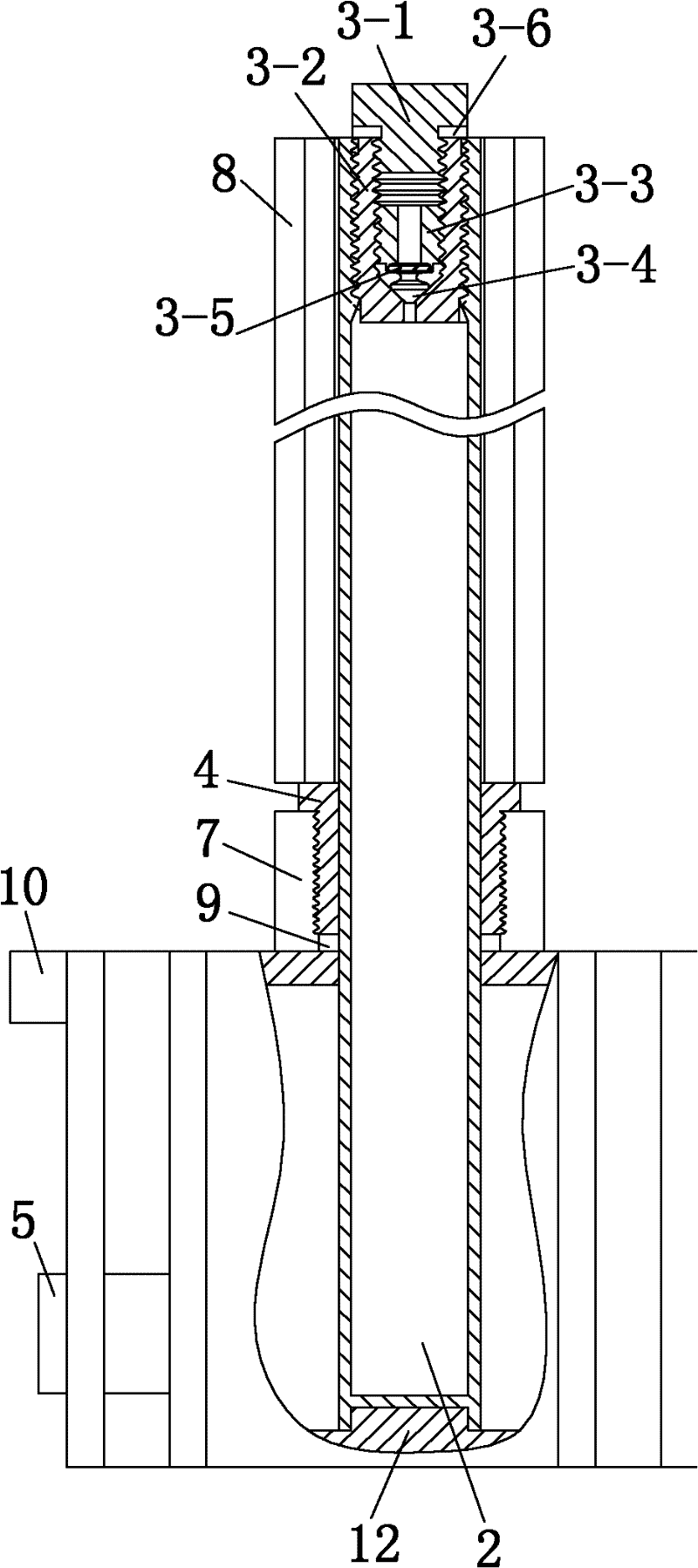

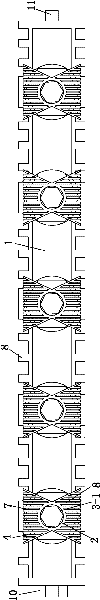

[0022] Such as Figure 1 to Figure 6 As shown, the single-pipe vacuum radiator of the present invention includes a water tank 1, a cooling pipe 2, a vacuum valve 3 and a hollow outer hex nut 4. The shape of the water tank 1 is roughly a rectangular parallelepiped water tank, made of cast iron material, and its exterior is welded with aluminum Special-shaped heat sink 8; one end of the water tank 1 is provided with a water inlet 5, and the other end is provided with a water outlet 6; the top of the water tank 1 is welded with a plurality of cooling pipe sockets 7, and the bottom is correspondingly cast with a plurality of fixing seats 12; the hollow outer hexagon The nut 4 is located in the radiating pipe socket 7, and is connected with the radiating pipe socket 7 by threads; The phase change medium can be acetone or ethylene glycol or a mixture of the two, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com