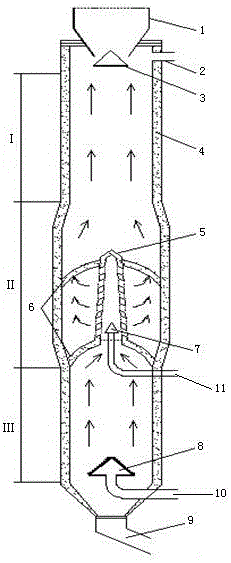

An internal gas fired shaft kiln and method for producing light-fired magnesia

A technology of lightly burning magnesia and internal gas, applied in the field of non-ferrous metal smelting, can solve the problems of waste of resources, product quality, uneven heat transfer, low degree of automation, etc., to shorten the calcination time, uniform heat transfer speed, heat transfer speed quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: Put the magnesite raw material with a particle size range of 30-80mm in a shaft kiln, preheat and dry it in high-temperature flue gas for 20 minutes, then calcinate it at 900°C for 30 minutes, and then cool it rapidly in the air to obtain a light-burned magnesium product. 92.3%, iodine adsorption value 90mgl / g.

Embodiment 2

[0024] Example 2: Put the magnesite raw material with a particle size range of 30-80mm in a shaft kiln, preheat and dry it in high-temperature flue gas for 20 minutes, then calcinate it at 900°C for 45 minutes, and then cool it rapidly in the air to obtain a light-burned magnesium product. 92.2%, iodine adsorption value 92mgl / g.

Embodiment 3

[0025] Example 3: Put the magnesite raw material with a particle size range of 30-80mm in a shaft kiln, preheat and dry it in high-temperature flue gas for 20 minutes, then calcinate it at 1100°C for 30 minutes, and then cool it rapidly in the air to obtain a light-burned magnesium product. 92.8%, iodine adsorption value 91mgl / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com