New Applications of Magnetic Ionic Liquids

A magnetic ionic liquid, anion and cation technology, applied in the direction of heat exchange materials, preparation of organic compounds, preparation of halogenated hydrocarbons, etc., can solve the problems of low power conversion efficiency, low energy conversion efficiency, poor heat transfer effect, etc., to achieve Fast heat generation rate, good thermal stable phase, and less heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Synthesis of poly-3,4-ethylenedioxythiophene nanospheres by heating using magnetic ionic liquid electric heat generation

[0023] (1) Preparation of magnetic ionic liquid, reference "Discovery of a magnetic ionic liquid[bmim]FeCl 4 》The method in preparation 1-butyl-3-methyl iron tetrachloride salt ([bmim]FeCl 4 )stand-by;

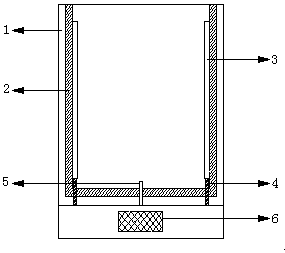

[0024] (2) Weigh the magnetic ionic liquid [bmim]FeCl according to the volume ratio of 2:1 4 and 3,4-ethylenedioxythiophene mixed in figure 1 In the shown reaction device, the voltage is set to 30V, and the reaction temperature is set to 45°C. At this time, an electric field is formed between the electrode plates 3, and the anions and cations of the magnetic ionic liquid move, migrate, and collide with each other under the action of the electric field force, and the electric energy is converted into heat energy. , to rapidly heat up and provide heat for the polymerization reaction. When the temperature detector 5 detects that the temp...

Embodiment 2

[0028] Example 2: Thermally cracking cellulose by using magnetic ionic liquid to generate heat

[0029] (1) Preparation of magnetic ionic liquid, refer to "Synthesis and characterization of theiron-containing magnetic ionic liquids" to prepare magnetic ionic liquid N-butylpyridine tetrachloride ([bPy]FeCl 4 ) and N-butylpyridine tetrachloride ([bmP]FeCl 4 )stand-by;

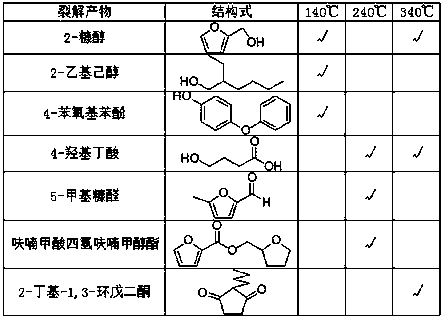

[0030] (2) Weigh the magnetic ionic liquid [bPy]FeCl according to the mass ratio of 5:5:1 4 , [bmP]FeCl 4 Mix with cellulose powder in the reaction device, respectively set DC voltage 80V, reaction temperature 140°C; AC voltage 150V, temperature 240°C; AC voltage 220V, temperature 340°C for vitreous pyrolysis reaction for 2 hours, the reaction is completed Then turn off the power supply; the distribution of the main pyrolysis products of cellulose is shown in Table 2.

[0031] Table 2 Distribution of cellulose pyrolysis products at different temperatures

[0032]

[0033] It can be seen from Table 2 that th...

Embodiment 3

[0034] Example 3: Using magnetic ionic liquid to generate heat for heating and catalytic dehalogenation reaction

[0035] (1) Preparation of magnetic ionic liquid, reference "1-Butyl-3-methylimidazolium cobalttetracarbonyl [bmim][Co(CO) 4 ]: a catalytically active organometallic ionicliquid" method to prepare 1-butyl-3-methyl tetracarbonyl cobalt salt ([bmim][Co(CO) 4 ])stand-by;

[0036] (2) Weigh the magnetic ionic liquid [bmim][Co(CO) at a mass ratio of 10:5:1 4 ], NaOH and 2-naphthyl bromomethyl ketone were mixed in the reaction device, set the DC voltage to 55V, and the temperature to 85°C, and heated the catalytic reaction for 1h, and turned off the power after the reaction was completed. The method can heat and catalyze 2-naphthyl bromomethyl ketone to remove bromine and convert it into 2-naphthylethanone (as shown in formula 1), and the conversion rate can reach 100%.

[0037] Formula 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com