Automatic splicing machine for joints of steel wire cords

A technology of automatic splicing and steel cord, which is applied to tires, other household appliances, household appliances, etc., can solve the problems of easy misalignment of joints, long sequence time, and poor quality, so as to achieve less deviation, improve production efficiency, and save energy. The effect of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, technical scheme of the present invention is described further:

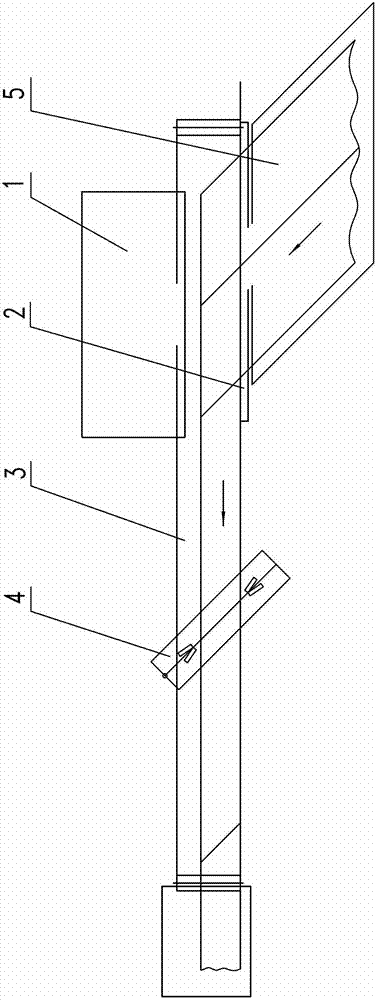

[0022] The automatic splicing machine for steel cord joints of the present invention is mainly composed of a clamping and transferring device 1 , a cutting device 2 , a servo conveyor belt 3 and a splicing device 4 .

[0023] The servo conveyor belt 3 is placed horizontally in the left and right directions, and the right end is the starting end of the servo conveyor belt 3; The conveyor belt 3 is set; the clamping and transferring device 1 composed of two-axis servo-driven pneumatic clamping rods is installed behind the cutting device 2; the cord 5 is arranged in front of the cutting device 2, and the arrangement direction of the cord 5 is perpendicular to the servo conveyor belt 3 The longitudinal direction; the splicing device 4 is arranged above the servo conveyor belt 3 through the screw nut transmission mechanism, the screw direction of the screw nut tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com