Automatic edge cutter of textilene mesh fabric setting machine

A technology of setting machine and edge trimmer, which is applied in the field of machinery, can solve the problems of rough edges of mesh cloth, not beautiful and delicate edges, influence of mesh size, etc. The effect of excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

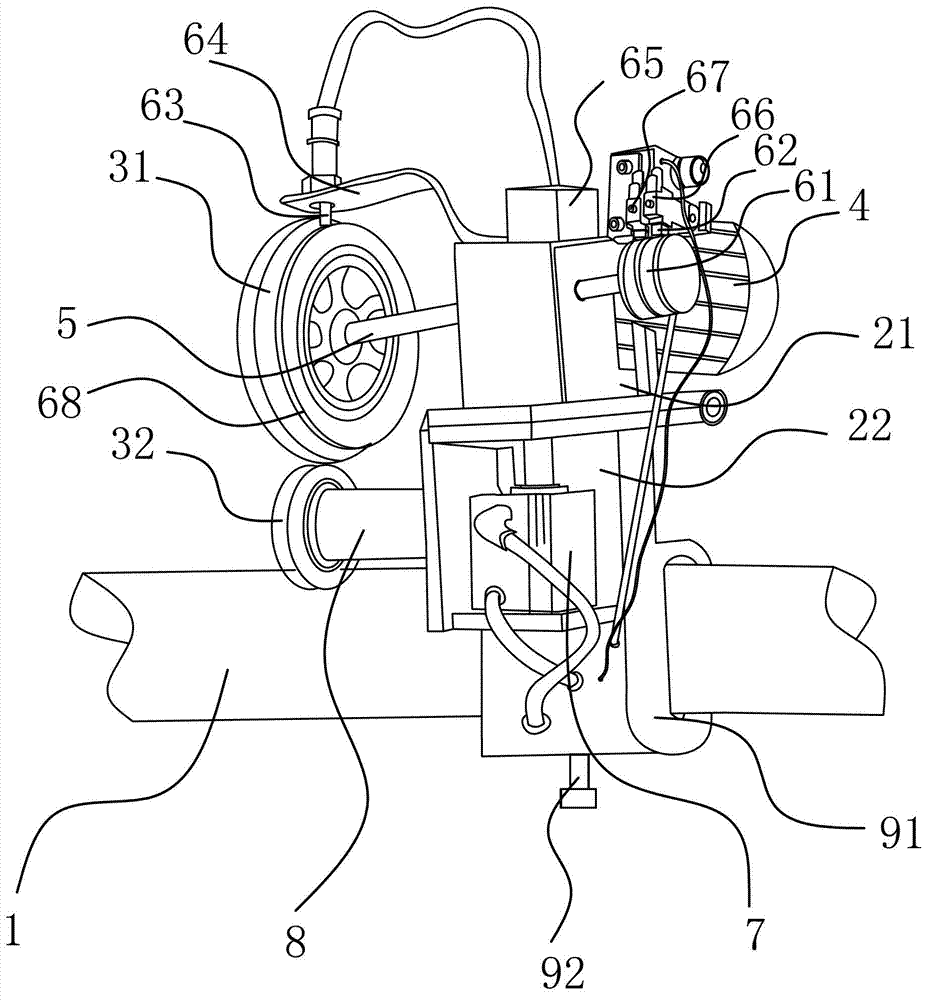

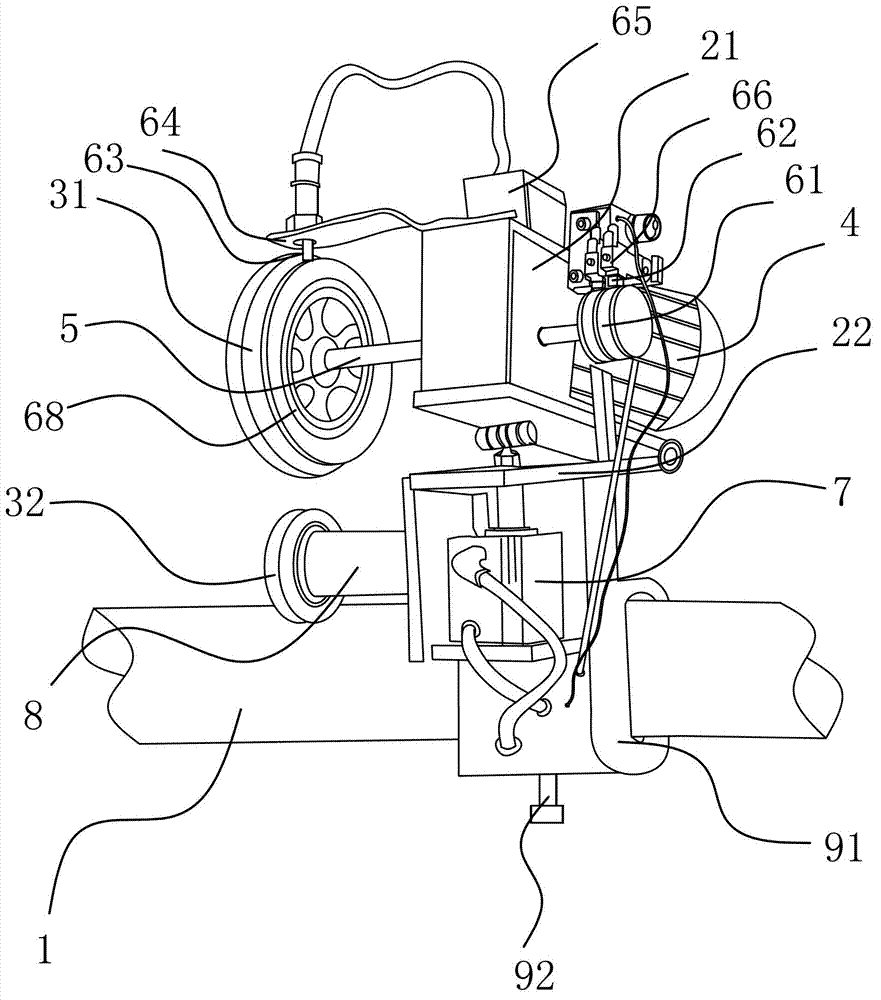

[0024] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0025] The edge cutter of the Teslin mesh setting machine needs to adjust the position of the upper cutter head 31 and the lower cutter head 32 before starting to work, and according to the thickness of the mesh, the gap between the upper cutter head 31 and the lower cutter head 32 It also needs to be adjusted, so the edge cutter can be in two states, namely the adjustment state and the working state.

[0026] Such as figure 2 As shown, the Teslin mesh sizing machine originally includes a beam 1 erected at the outlet of the cloth. The edge trimmer includes an upper base body 21 and a lower base body 22 connected to the beam 1. The upper base body 21 is provided with a passing motor. 4 driven upper cutterhead 31, the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com