Construction process for back-sloping and jacking curved bridge

A construction technique and curved bridge technology, which is applied to bridges, bridge maintenance, bridge reinforcement, etc., can solve problems affecting the lifting of box girders, achieve safety and reliability, and ensure installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

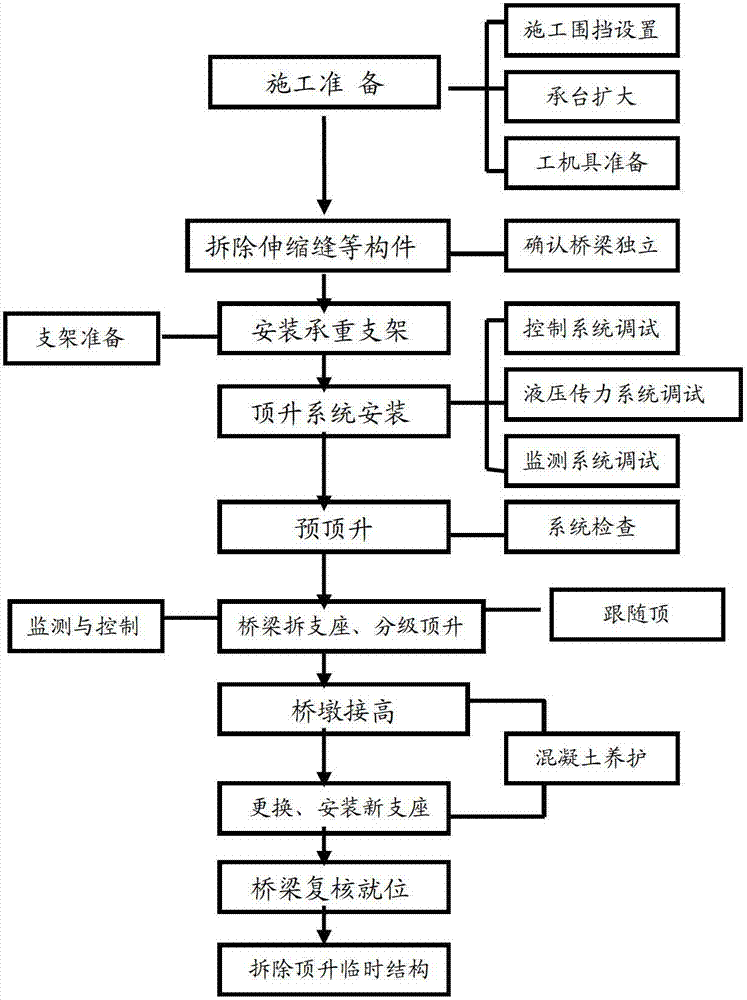

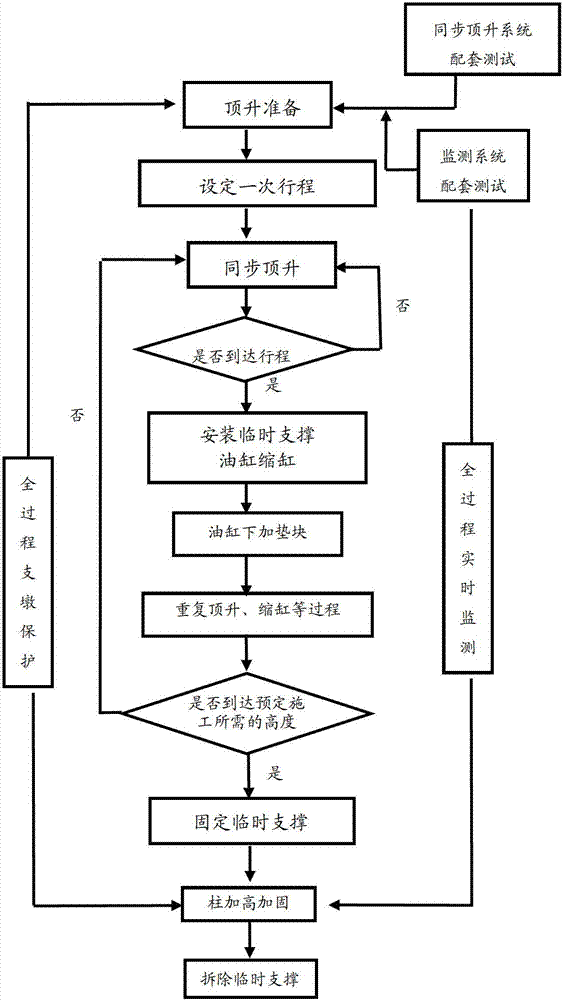

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

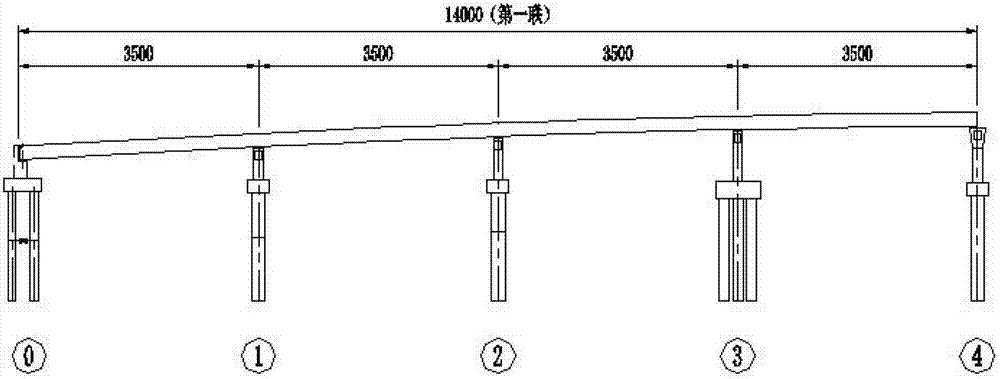

[0030] see figure 1 , the bridge shown is a prestressed concrete box girder of 4×35 equal height, the front section 119.919m is located on the R=600m flat curve, the rear 20.081m is located on the Ls=80m transitional curve, the flat curve is superhigh by 1.5%, and there is 5.01% longitudinal slope. Bridge piers H1, H2, H3, and H4 adopt a double-rectangular portal pier body with slightly open upper ends, bored pile foundations, piles and columns corresponding, single row of pile diameters connected by a platform. H0 abutment is 25.1mx5.4m, with 10 double-row piles and pile diameter

[0031] Since the bridge is a continuous box-girder bridge with a small-radius curved body, the spatial curve of the bridge is complex. During the process of ja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com