Fuel oil evaporation system and motorcycle thereof

A fuel evaporation system, motorcycle technology, applied in the direction of charging system, engine components, machine/engine, etc., can solve the problems of complicated connection process, deformation and bending of ventilation pipes, blockage, etc., to simplify installation procedures and reduce installation space , The effect of simplifying the installation structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

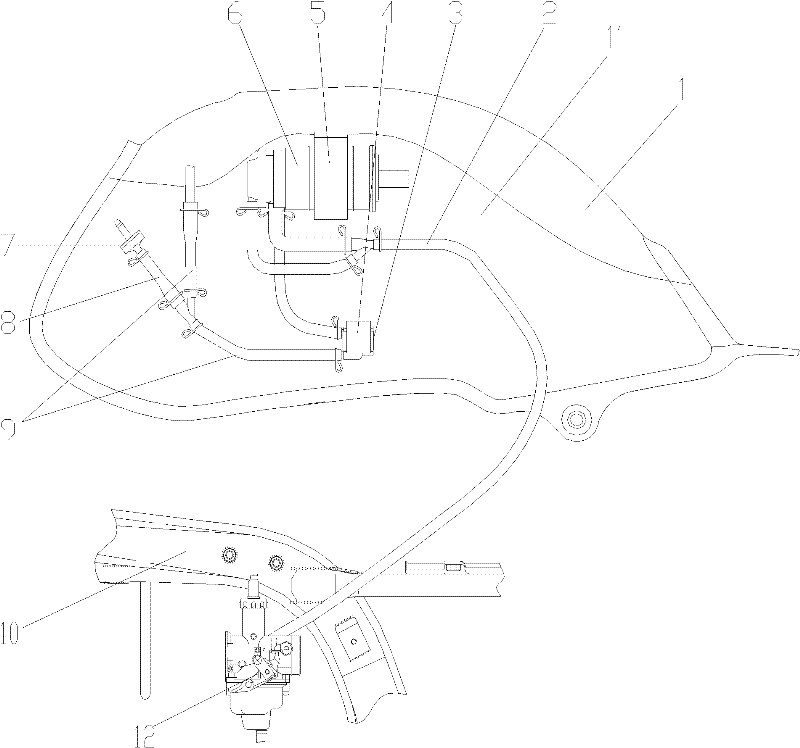

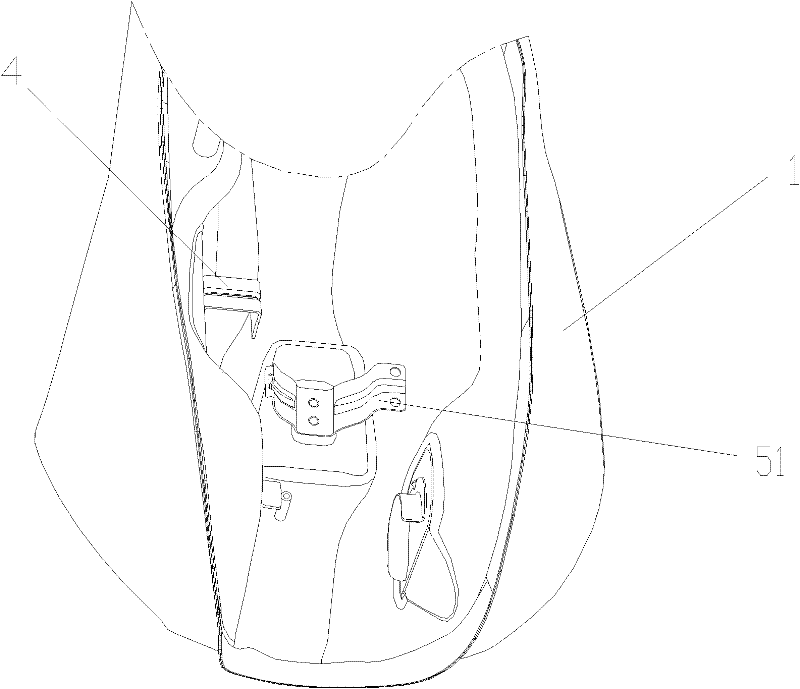

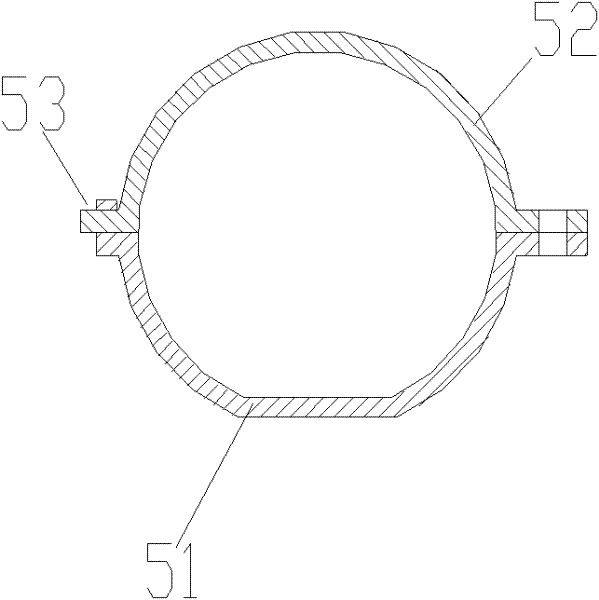

[0021] figure 1 It is a structural schematic diagram of the present invention, figure 2 is the bottom view of the fuel tank, image 3 It is a schematic diagram of the structure of the canister mounting bracket, Figure 4 It is a schematic diagram of the installation of the dump valve, as shown in the figure: the fuel evaporation system of this embodiment includes a carbon canister 6 and a pipeline system. The carbon canister 6 is fixed on the lower surface of the bottom plate of the fuel tank 1. Air pipe I 9 and air pipe II 2, one end of the air pipe I 9 communicates with the gas phase of the fuel tank oil-gas separator, and the other end communicates with the fuel vapor inlet of the charcoal tank 6, and the air pipe I 9 pipeline is provided with a dump valve 3, said The dump valve 3 is fixed on the lower surface of the bottom plate of the fuel tank 1, one end of the vent pipe II 9 is connected to the desorption port of the carbon tank 6, and the other end is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com