Construction treatment method of composite pile wall connected by row

A processing method and technology for composite piles, which are applied in sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of polluting the surrounding environment, time-consuming and labor-intensive, and large engineering volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technology of the present invention will be described in further detail below in conjunction with accompanying drawing and specific implementation:

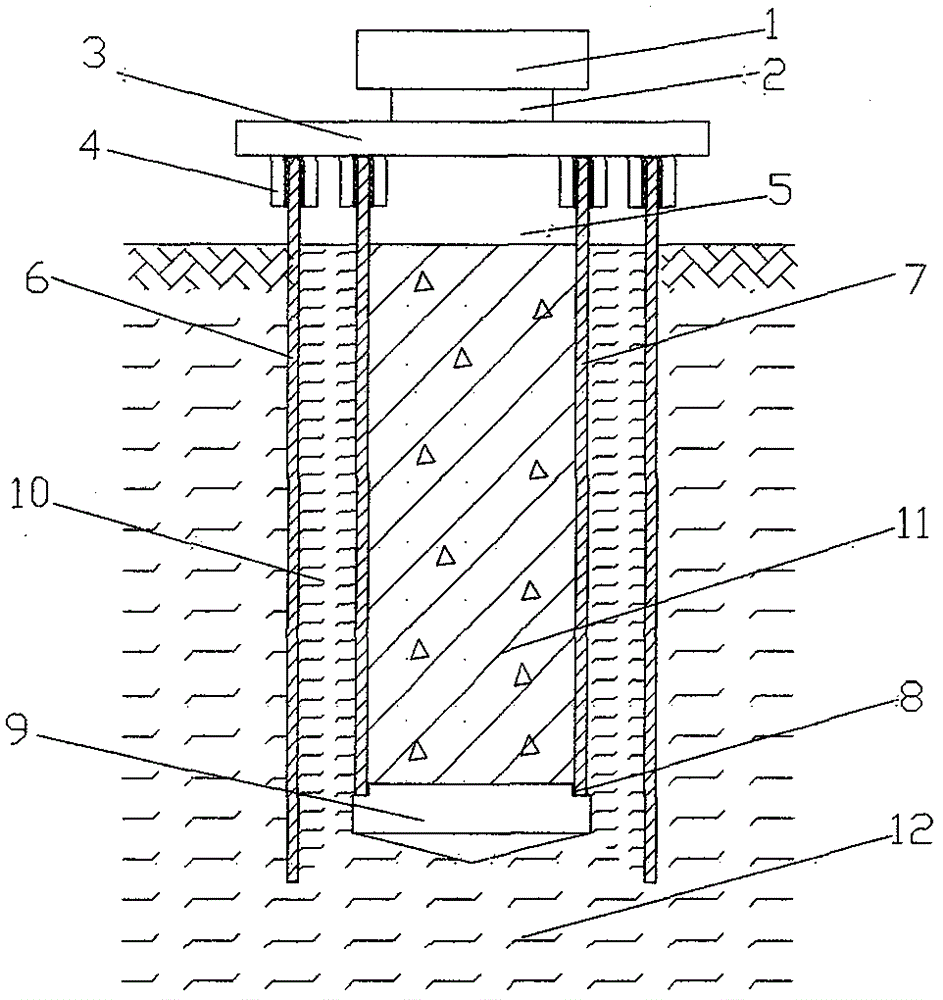

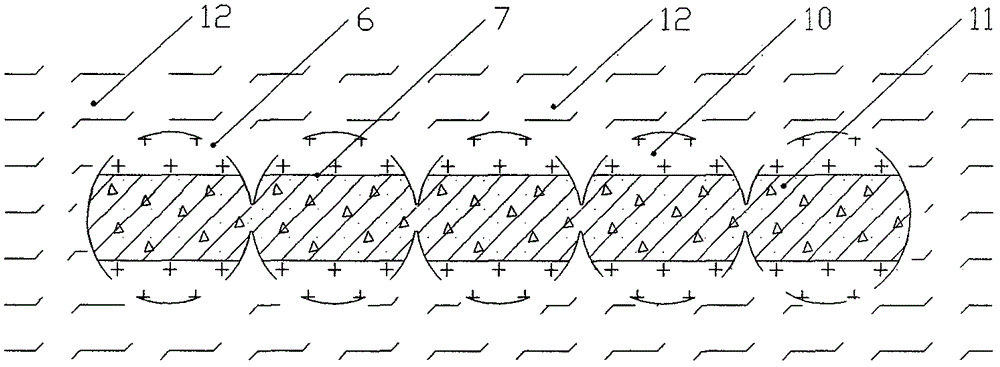

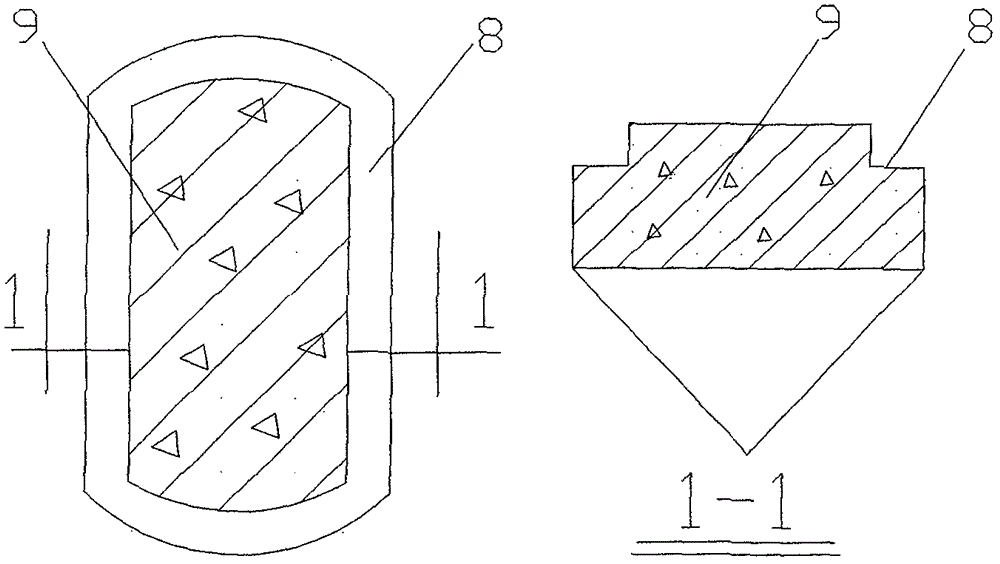

[0024] One, as attached figure 1 , 2 , 3, 4, what the present invention provides is a kind of vibration hammer with medium and high frequency hydraulic or electric 1 , flange 2 , Fixture chute beam 3 , mobile telescopic chuck 4 The special fixture complex composed of equipment, and the outer steel casing 6 and inner steel casing 7 The upper part is clamped so that the inner steel casing 7 The bottom end is embedded in the reinforced concrete solid pile tip 9 upper outer groove 8 , start the medium and high frequency hydraulic or electric vibratory hammer 1 Implement vibration pressure to make the outer steel casing 6 , inner steel casing 7 and reinforced concrete sealed solid pile tips 9 The combination is quickly and simultaneously vibrated into the underground soil layer and slowly vibrated to pull out th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com