Supporting insulation structure for refuge chamber of deep well under high-temperature geological conditions

A technology for geological conditions and refuge chambers, applied in safety devices, mining equipment, earthwork drilling and mining, etc., can solve problems such as difficult cooling power to adjust chamber temperature, and achieve the effect of reducing heat load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

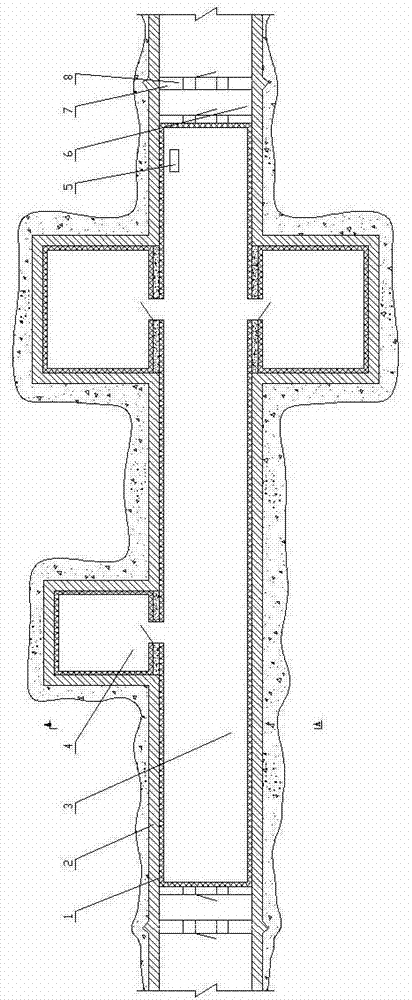

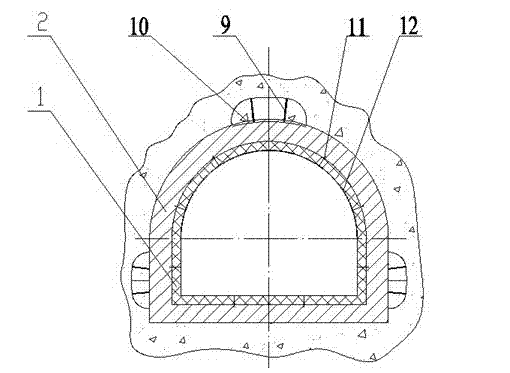

[0019] The surrounding rock around the refuge chamber is first supported by anchor rods 9, steel mesh 10 and sprayed layer, and then the concrete structure layer 2 is built to ensure the stability of the shape of the chamber. On this basis, according to the rock temperature conditions and the living environment temperature required by the refuge chamber, the thickness of the insulation layer is preliminarily determined to be 50-300mm. The specific value of the thickness is initially selected during design, the heat transfer is calculated according to the parameters of the polyurethane material, and the cooling equipment is selected. According to the equipment selection results, optimize the insulation thickness and equipment selection matching technical scheme.

[0020] During the construction of the insulation layer, the formwork is used to lay the polyurethane material on the inner surface of the chamber. After the material is formed, in order to ensure that the insulation ...

Embodiment 2

[0022] Anchor mesh spraying, concrete construction and other methods are adopted around the refuge chamber to ensure the stability of the chamber shape. On this basis, according to the rock temperature conditions and the living environment temperature required by the refuge chamber, the thickness of the insulation layer is preliminarily determined to be 50-300mm. The specific value of the thickness is initially selected during the design, and the heat transfer is calculated according to the parameters of the thermal insulation material, that is, the foamed cement prefabricated block, and the cooling equipment is selected. According to the equipment selection results, optimize the insulation thickness and equipment selection matching technical scheme.

[0023] Before the construction of the insulation layer, prefabricated foamed cement insulation blocks according to the shape of the chamber, or customized from professional building insulation materials. During construction, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com