Silicon micro resonant type pressure sensor and manufacturing method thereof

A pressure sensor, resonant technology, applied in the direction of measuring fluid pressure, piezoelectric devices/electrostrictive devices, measuring fluid pressure through electromagnetic components, etc., can solve the problem that the quality factor affects the strong vacuum of the package, affects the resonance frequency, and changes in stiffness and other problems, to achieve the effect of reducing design difficulty, reducing process complexity, and increasing measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

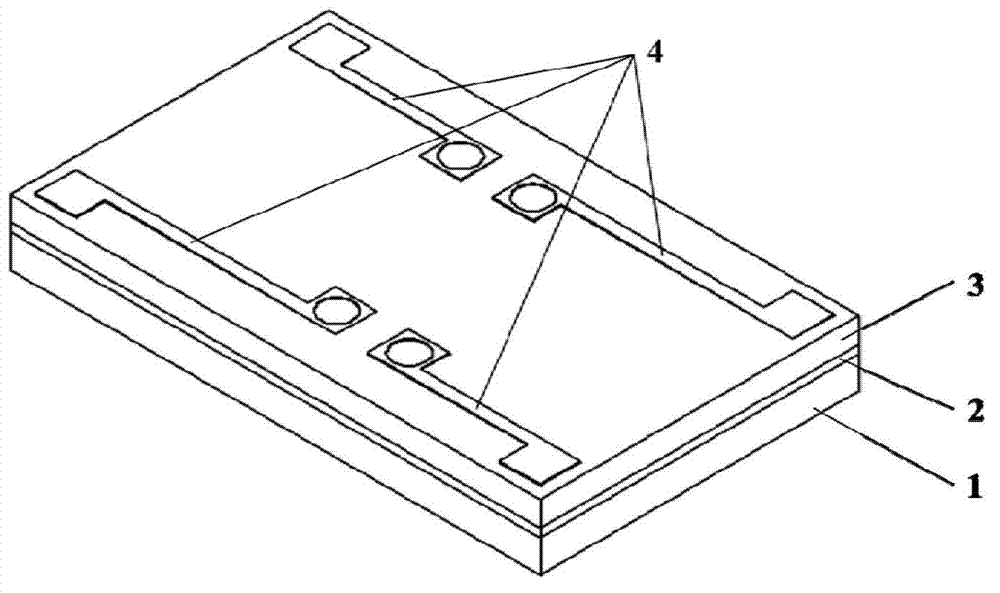

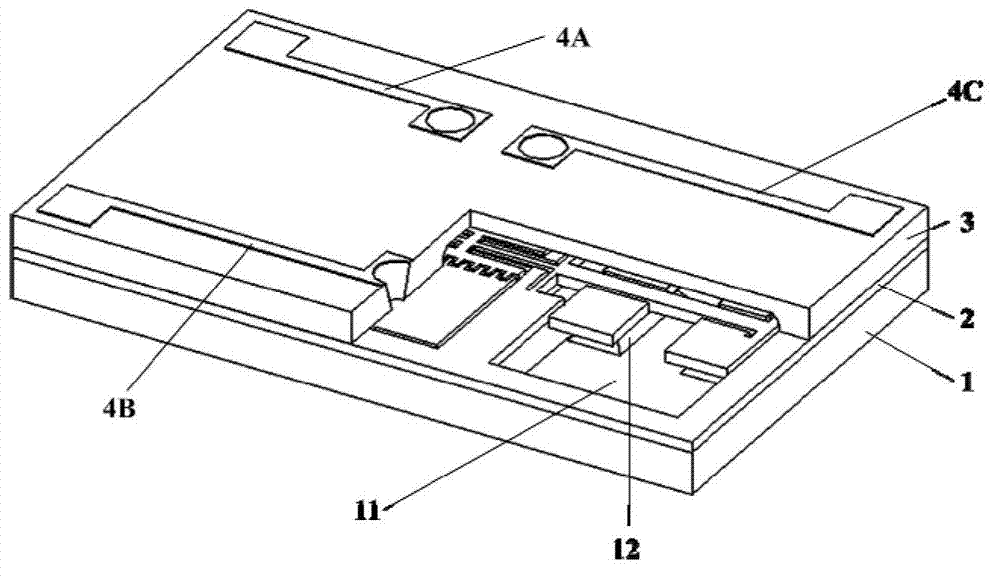

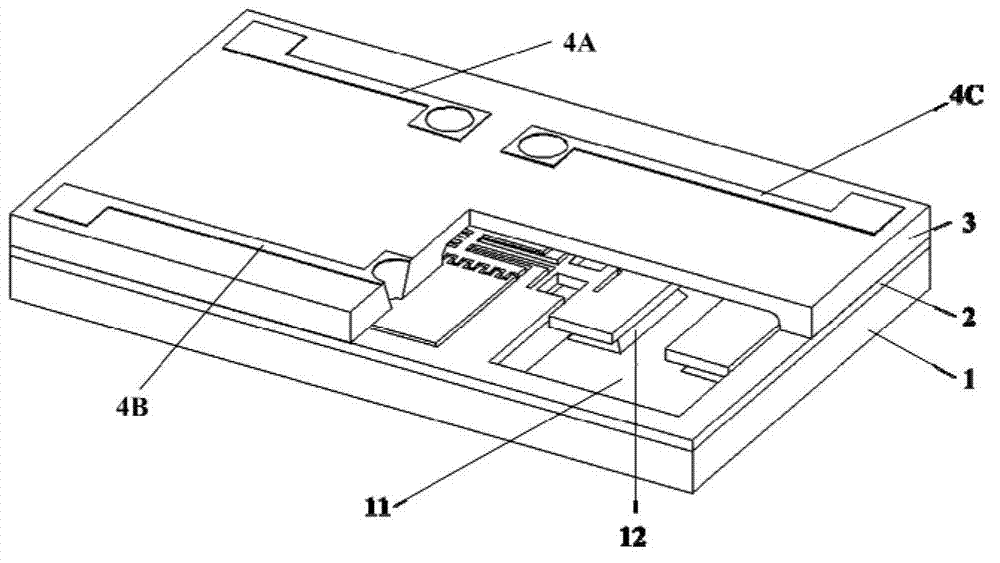

[0047] see Figure 1-7 , the embodiment of the present invention is provided with a pressure sensitive layer 1, a resonant structure layer 2, a vacuum packaging cap layer 3 and a lead electrode 4, the upper part of the frame of the pressure sensitive layer 1 is connected with the lower part of the frame 21 of the resonant structure layer 2, and the pressure sensitive layer 1. Two pressure membranes 11 are arranged in the upper frame to form two cavities for placing parallel silicon islands 12. The tops of the silicon islands 12 are connected to the first transfer beam 23A and the second transfer beam 23B on the resonant structure layer 2. 2 There is a channel between the two cavities, so that the first resonant beam 27A, the second resonant beam 27B, the first mass 29A and the second mass 29B on the resonant structure layer 2 have space for free vibration, and the resonant structure layer 2 The upper part of the frame 21 is connected to the lower frame of the vacuum-encapsulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com