Real-time online monitoring method and device for cleaning losses of grain combines

A technology of combine harvester and monitoring device, which is applied in agricultural machinery and implements, threshing equipment, applications, etc., can solve the problems of high cleaning loss rate, low reliability of monitoring data, and high driving level requirements, so as to achieve enhanced grain size. Shock signal, improve test reliability, good overall dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

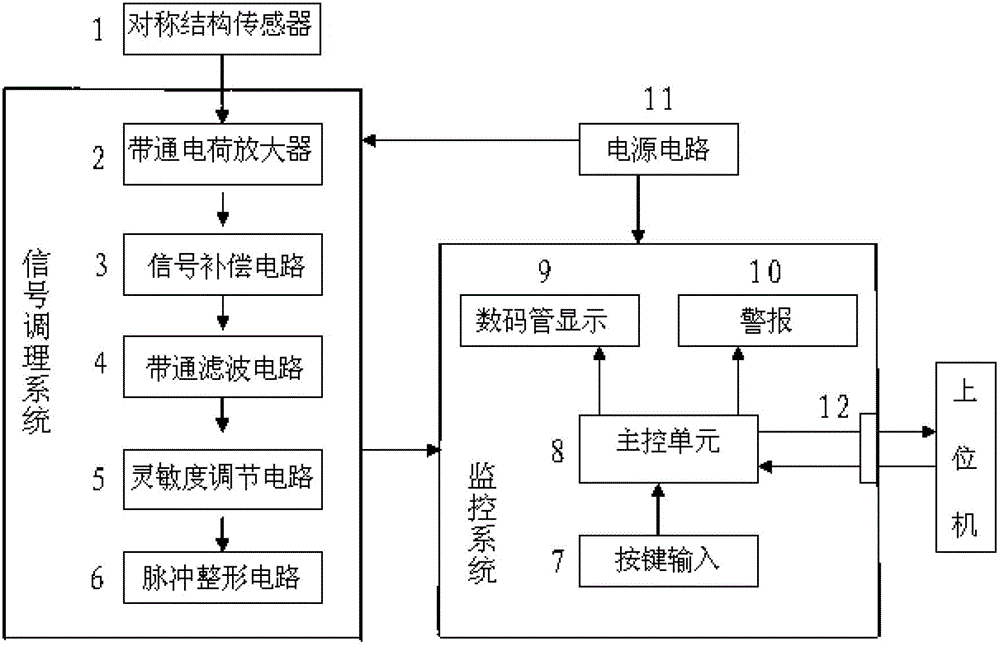

[0041] Example 1, such as figure 1 In the monitoring device shown, the output of the symmetrical piezoelectric crystal sensor 1 is connected to the band-pass charge amplifier circuit 2, and the output of the band-pass charge amplifier circuit 2 is sequentially connected to the signal compensation circuit 3, the band-pass filter circuit 4, the sensitivity adjustment circuit 5, the pulse Shaping circuit 6, single-chip microprocessor 8 and communication interface circuit 12. Wherein, the output of the single-chip microprocessor 8 is also connected to the display digital tube 9 and the alarm circuit 10 . The output of the keyboard 7 is connected to the single-chip microprocessor 8 . The power supply circuit 11 is respectively connected to the above-mentioned various circuits and provides power for each circuit. The power supply circuit 13 adopts the DC24V output from the storage battery on the combine harvester as its voltage input, and then provides the required voltage and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com