Fully-automatic tea flattening drying streamline

A fully automatic and assembly line technology, applied in tea processing before extraction, etc., can solve problems such as difficult quality assurance, reduced labor intensity, and low work efficiency, and achieve the effect of guaranteed tea quality, low labor intensity, and high tea production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

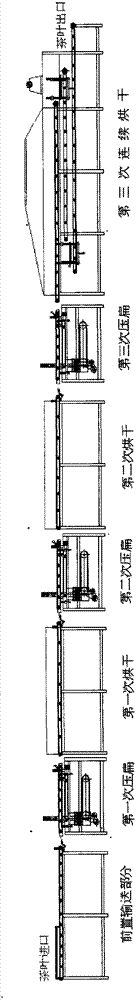

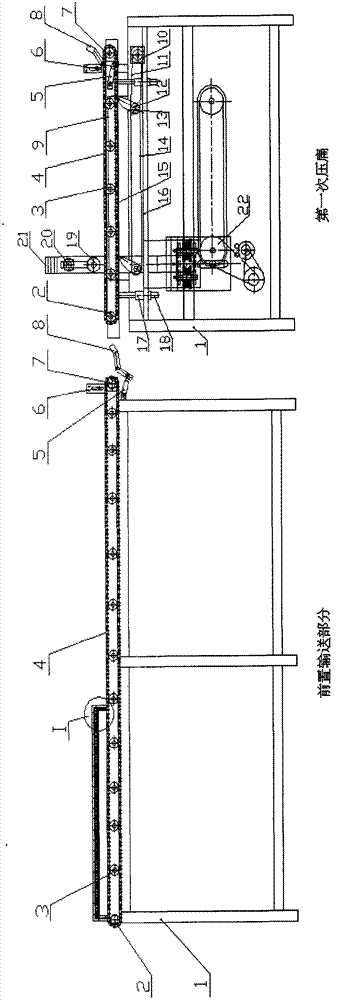

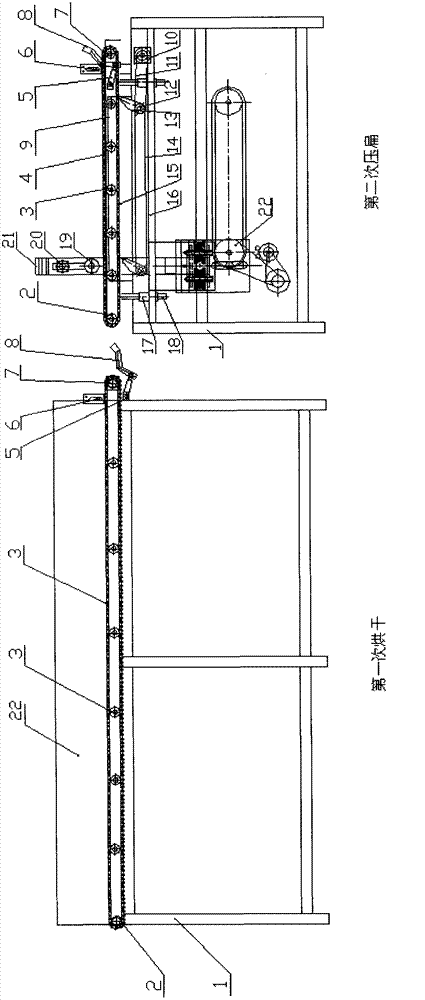

[0045] A full-automatic tea flattening and drying assembly line of the present invention is composed of a sieve part, a front conveying part, the first flattening, the first drying, the second flattening, the second drying, and the third pressing Flattening, terminal continuous drying and PLC controller, the tea leaves go through the production process of flattening, drying, secondary flattening, secondary drying, third flattening and final drying.

[0046] Sieve parts comprise outer sieve 35, gauze 36, tealeaves 37 and interior sieve 38, spread one deck gauze 36 in outer sieve 35, tealeaves 37 are piled on gauze 36 evenly, spread one deck gauze 36 again on tea leaves 37, will The inner screen 38 is counter-pressed onto the second layer of gauze 36 of the outer screen 35 .

[0047] When working, the sieve parts are bottom up.

[0048] The front conveying part includes frame 1, sprocket 2, roller 3, chain 4, speed regulating motor 7 and limit mechanism, sprocket 2, roller 3, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com