Dedusting device for automatically detecting and controlling dedusting filter cloth humidity

An automatic detection and dust removal device technology, applied in the direction of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of reduced working efficiency of dust collectors, easy adhesion on filter cloth, high humidity of filter cloth, etc., to achieve Simple structure, convenient operation and high dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with drawings and embodiments.

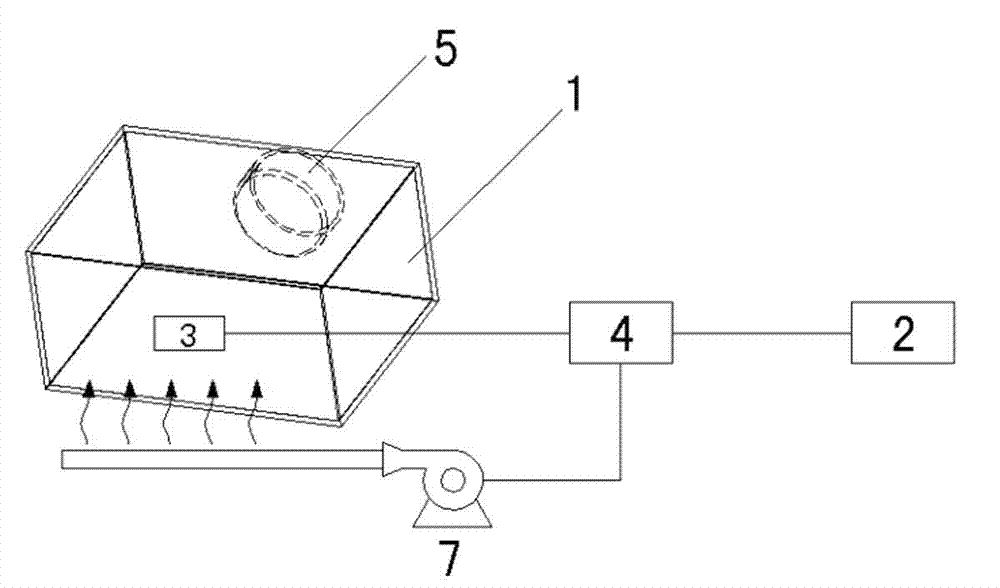

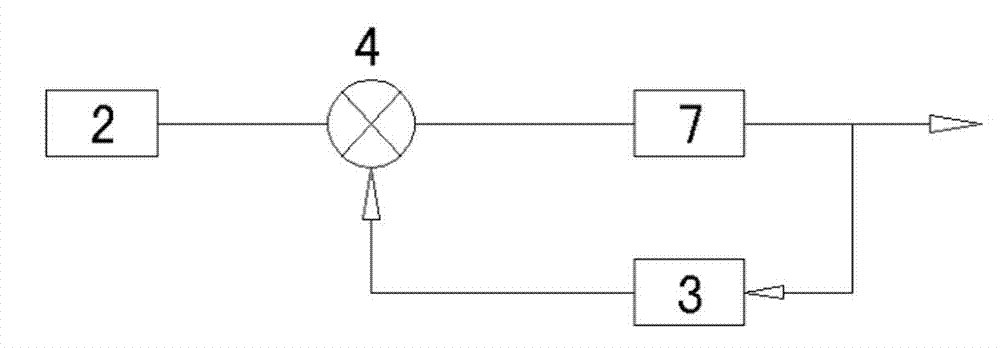

[0012] With reference to accompanying drawing, present embodiment comprises humidity sensor 3 and humidity given unit 2, and humidity sensor 3 is arranged on the filter cloth 1, and filter cloth 1 side is provided with air inlet pipe 5, and described humidity gives unit 2 output terminals and control The input terminal of the regulator 4 is electrically connected, the output terminal of the control regulator 4 is connected with the hair dryer 7 , and the feedback terminal of the control regulator 4 is connected with the humidity sensor 3 .

[0013] The humidity sensor 3, the control regulator 4, the hair dryer 7 and the humidity setting unit 2 constitute a humidity closed-loop control system.

[0014] The filter cloth 1 is fixed on the filter cloth supporting frame, the filter cloth supporting frame is a hexahedral supporting frame, and the six end faces of the hexahedr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com