Method for supporting ultra-thick and fluffy coal roadway

A support technology for soft coal seams and roadways, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc. It can solve problems such as soft coal seams, difficult support, and easy slabs, so as to strengthen the strength of surrounding rock, simple construction, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

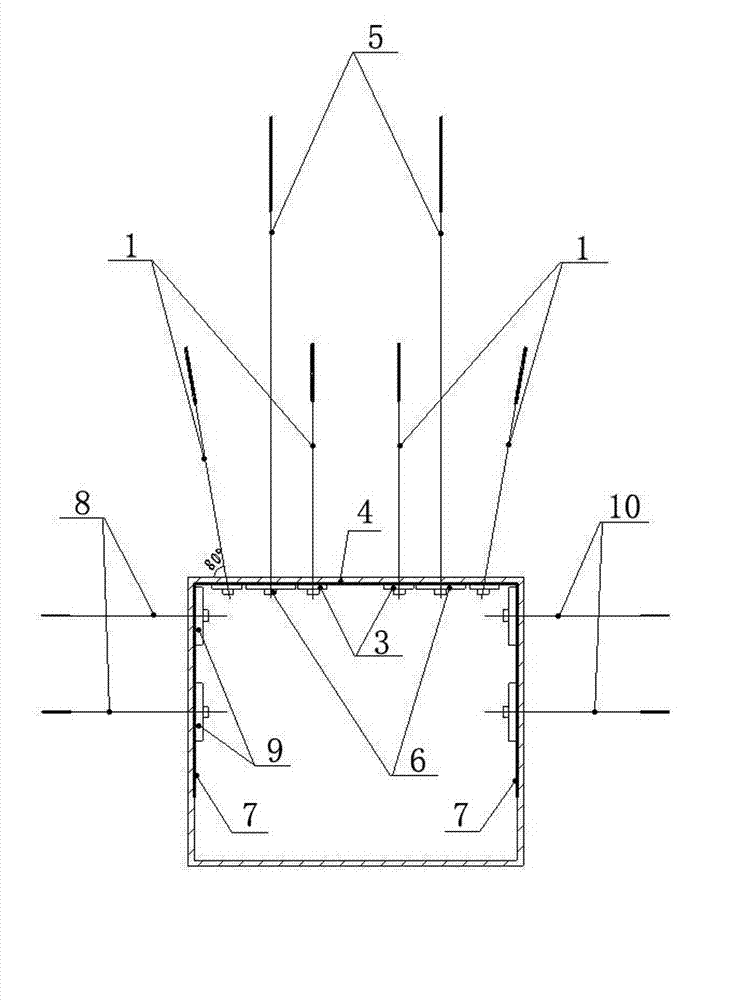

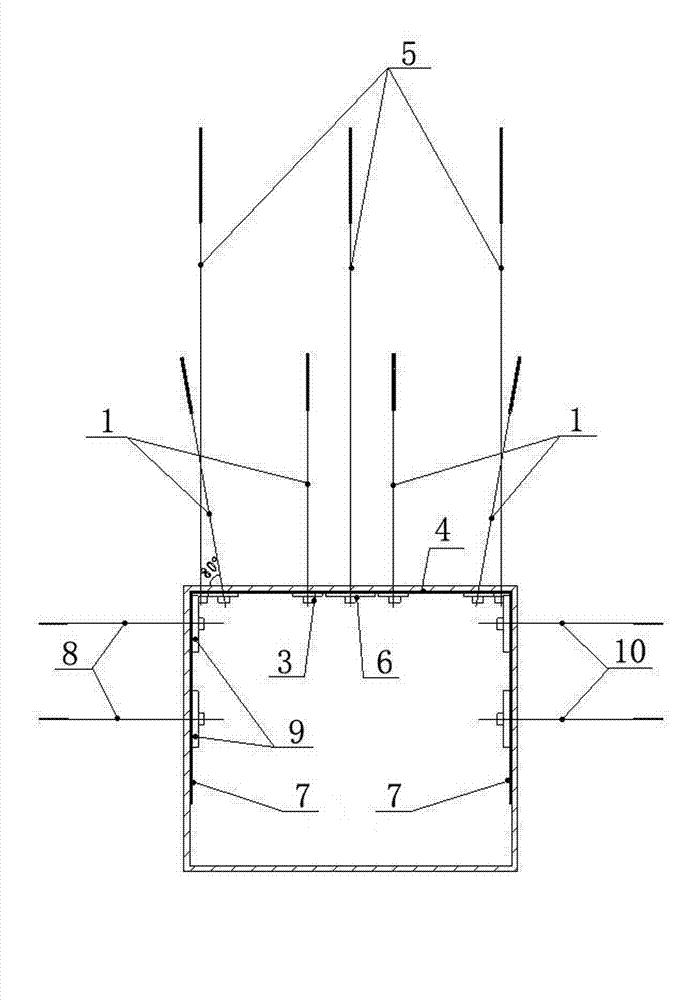

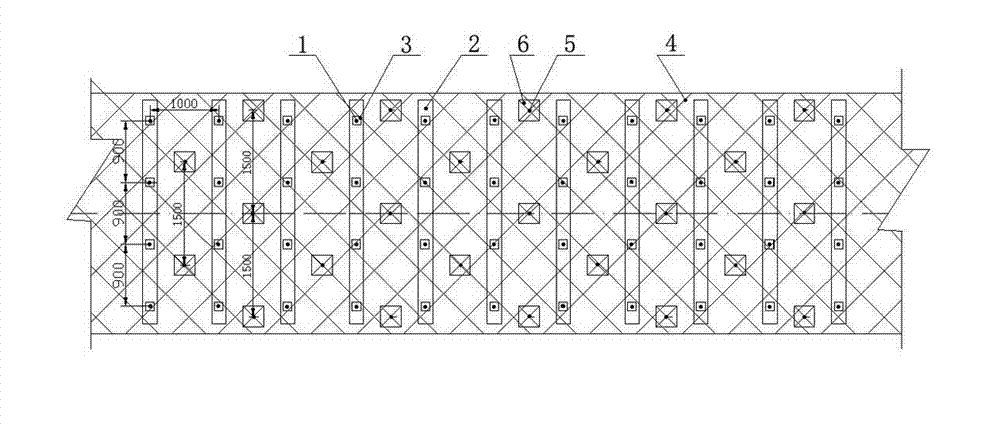

[0019] Such as Figure 1 to Figure 3 As shown, a method for roadway support in an extra-thick soft coal seam comprises the following steps:

[0020] 1) Support for the roof of the roadway: several rows of left-handed threaded steel resin anchor rods 1 without longitudinal reinforcement are uniformly fixed on the roof of the roadway, and the distance between two adjacent rows of left-handed screwed steel resin anchor rods 1 without longitudinal reinforcement is 1000mm; Rebar-free rebar resin anchor rod 1 includes four left-handed rebar-free rebar resin anchor rods 1 with a diameter of 18mm and a length of 2500mm, and the distance between two adjacent left-hand rebar-free rebar resin anchor rods 1 is 900mm , the two left-handed resin anchor rods 1 without longitudinal reinforcement are inclined and fixed towards the direction of their adjacent roadsides respectively, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com