Detecting gauge applicable to battery chamber

A technology for detecting jig and battery cavity, which is applied to measuring devices, mechanical devices, mechanical measuring devices, etc., can solve problems such as unfavorable industrial production and low efficiency, and achieve simple structure, high detection accuracy, and improved detection efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following describes the present invention in detail with reference to the drawings and specific embodiments.

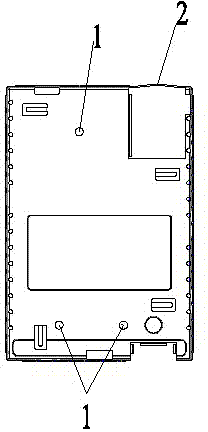

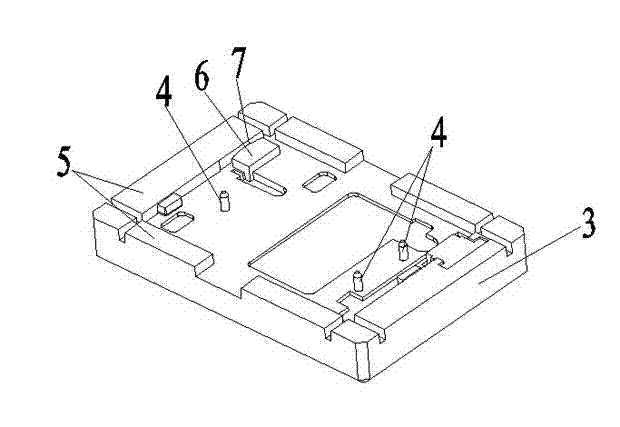

[0014] See figure 1 , The battery cavity includes a plurality of positioning holes 1 and a convex hull structure 2, and the distance between the convex hull structure 2 and the positioning hole 1 is a parameter that is the focus of attention during detection. In view of this, the present invention provides a figure 2 The shown testing fixture suitable for the battery cavity includes: a fixture main body 3, which is preferably made of a metal material. The jig body 3 is provided with a plurality of positioning posts 4 for matching with the positioning holes 1 of the battery cavity. Of course, the number of the positioning posts 4 and the distribution of the positioning holes 1 should correspond one to one. As a preference, the diameter of the positioning post 4 is smaller than the diameter of the positioning hole 1. When the two are matched, a displacement wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com