Temperature online monitoring system for liquid aluminum in aluminum ladle based on acoustic temperature detection and method

A monitoring system and aluminum-clad technology, which is applied to thermometers, thermometers, measuring devices, etc. with physical/chemical changes, can solve the problems of large temperature measurement errors, high costs, and fluctuations in temperature measurement results, so as to improve internal quality and save money. Labor, the effect of favoring control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention provides an on-line monitoring system and method for the temperature of molten aluminum in aluminum cladding based on acoustic temperature measurement. The present invention will be further described below in conjunction with the accompanying drawings and specific implementation methods.

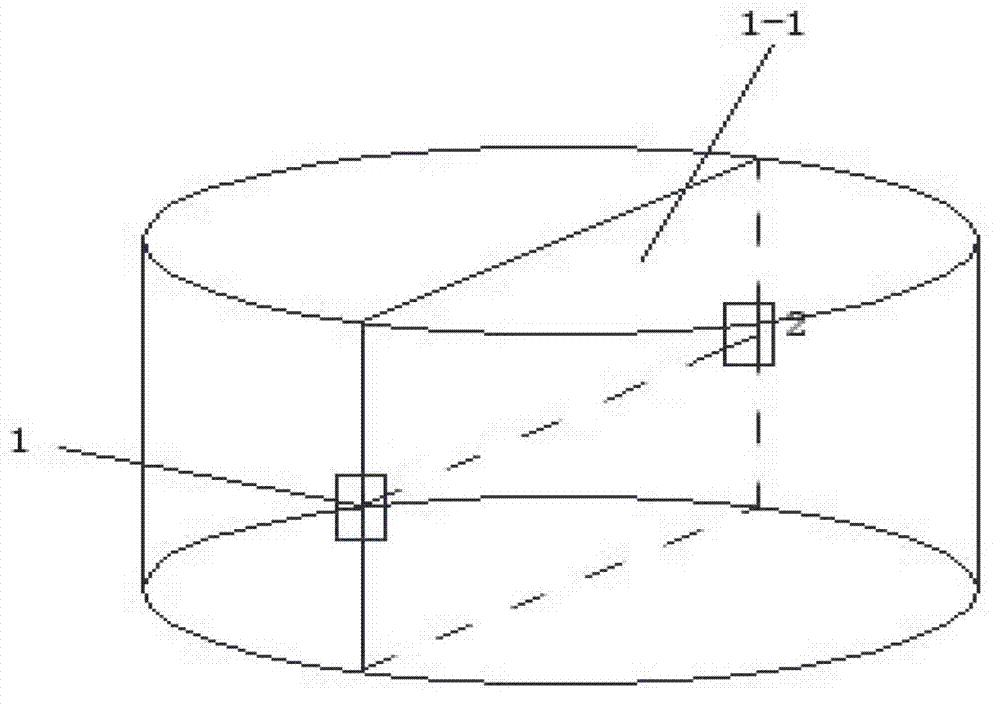

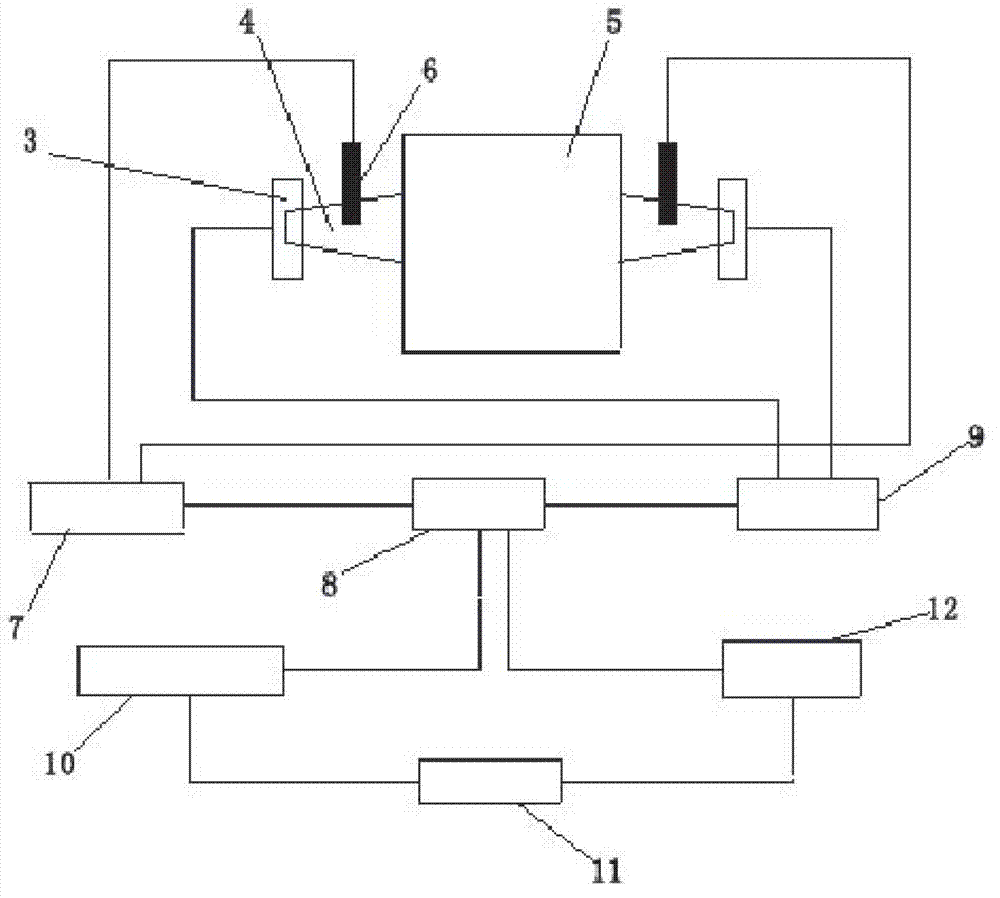

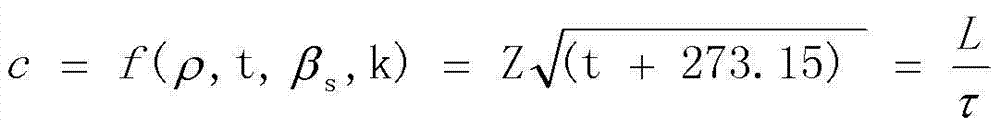

[0019] An on-line monitoring system for the temperature of aluminum water in an aluminum ladle based on acoustic temperature measurement, characterized in that the system installs two acoustic waveguides 4, 2 symmetrically through flanges on the same vertical section in the middle of both sides of the cylindrical aluminum ladle 5 A microphone 6 is respectively arranged on each sound waveguide 4, and two sound waveguides 4 are connected with an electric speaker 3 respectively; a signal conditioner 7 is connected with two microphones 6 and a junction box 8 respectively, and a power amplifier 9 is connected with two electric speakers respectively. The loudspeaker 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com