Heat metering system for organic heat carrier

A metering system and heat energy technology, applied in the field of organic heat carrier heat energy metering system, can solve problems such as inability to accurately measure organic heat carrier heat energy, and achieve the effect of improving modern management level, good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

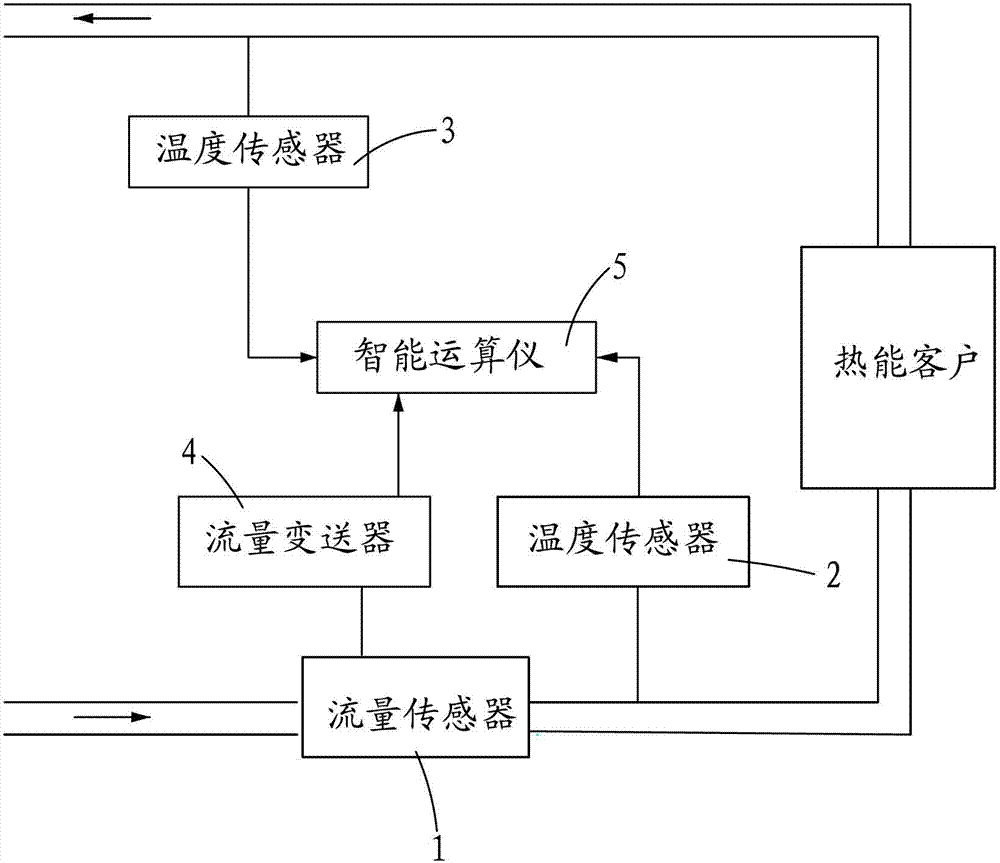

[0013] Such as figure 1 As shown, the organic heat carrier thermal energy metering system includes a flow sensor 1 , a temperature sensor 2 , a temperature sensor 3 , a flow transmitter 4 , and an intelligent computing instrument 5 .

[0014] The flow sensor 1 and the temperature sensor 2 are respectively arranged on the heat energy input pipeline. The flow transmitter 4 is connected with the flow sensor 1; the temperature sensor 3 is arranged on the heat output pipeline.

[0015] The temperature sensor 2, the temperature sensor 3, and the flow transmitter 4 are respectively connected with an intelligent computing instrument 5.

[0016] This system adopts a single flow sensor system. This system assumes that the oil supply flow is equal to the oil return flow. Based on the mass flow measurement of the heat transfer oil, the heat flow is calculated, or on this basis, the oil return loss is calculated by agreement between the supplier and the buyer. as compensation.

[0017] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com