Water quality monitoring water collecting tank

A water quality monitoring and water tank technology, applied in the direction of sampling devices, etc., can solve the problems of water samples not reaching the monitoring accuracy, poor sealing performance, and increased difficulty of monitoring work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

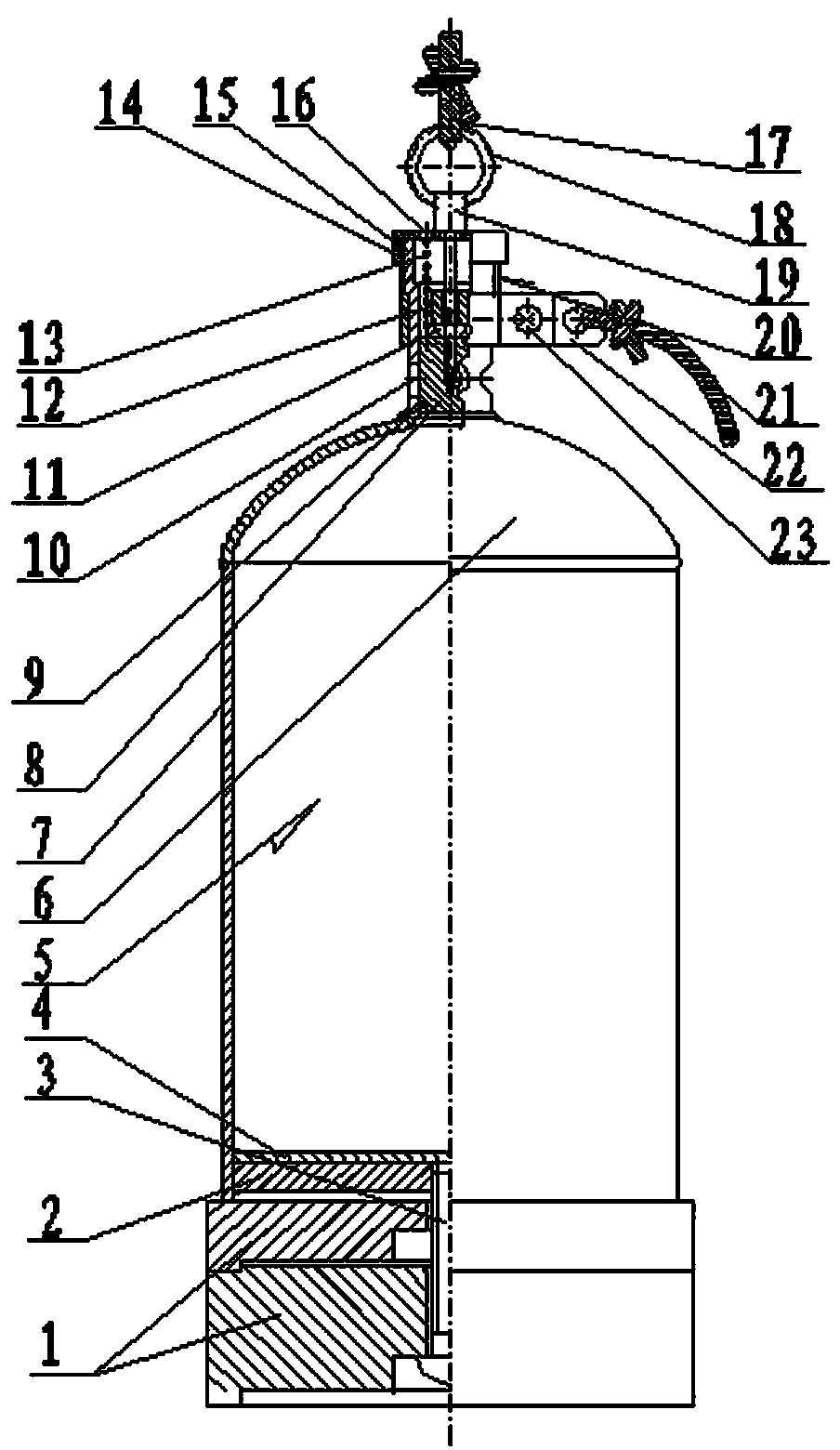

[0011] The water quality monitoring water intake tank includes a tank body 5, a tank mouth 20, a counterweight 1, a measuring rope 21 and a cork cord 17. The tank body 5 is composed of a stainless steel cylinder 7 whose upper and lower ends are respectively welded with a stainless steel spherical head 6 , a tank bottom 2 and a lining plate 4 . The can mouth 20 includes a piston 8 , a piston sleeve 15 , a mouth cover 14 , a spring 13 , lag bolts 19 , and a limit sleeve 12 . The lower part of the piston sleeve 15 is provided with four evenly distributed water inlet holes 10, the piston sleeve 15 is equipped with a piston 8, the piston 8 is covered with an O-shaped rubber ring 9, and the O-shaped rubber ring 9 is installed in the groove provided by the piston, so that the piston 8 Seal with the piston sleeve 15. The mouth cover 14 is provided with a flat pressure hole 16 which is beneficial to the up and down movement of the piston and balances the water pressure difference betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com