Oil-gas pipeline polarization potential monitoring device

A technology for monitoring devices and polarization potentials, applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of inability to monitor the cathode of oil and gas pipelines, and cannot effectively dynamically reflect the polarization potential of oil and gas pipelines, etc., to achieve The effect of eliminating the influence of interference and stray current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiment. The specific embodiment of the present invention is described with this example and the present invention is described further. This example is an experimental prototype.

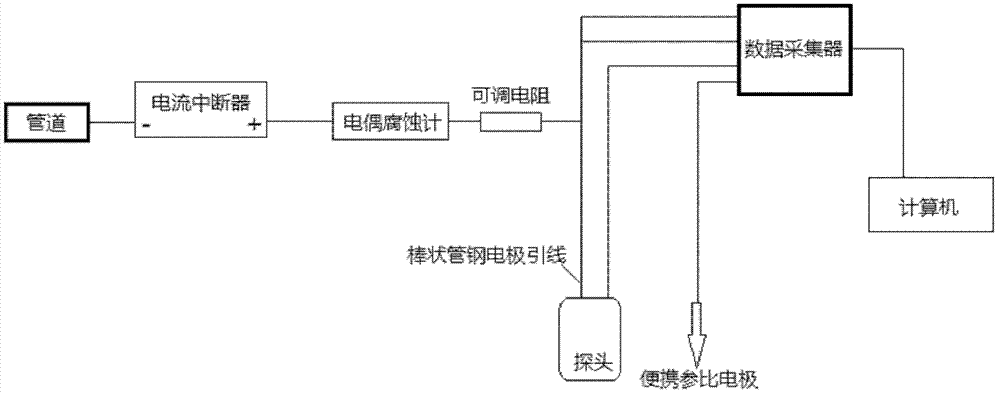

[0029] This example consists of a current interrupter, a galvanic corrosion meter, an adjustable resistance, a data collector, a probe, a portable reference electrode, and a computer (see figure 1 ).

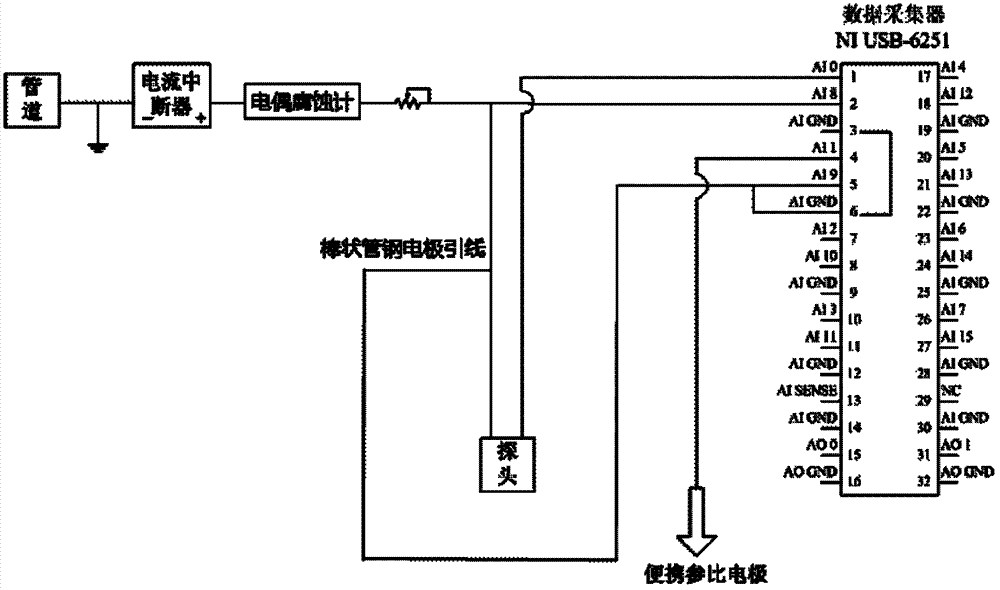

[0030] Electrical schematic diagram see figure 2 , the negative terminal is connected to the pipeline test pile or the current interrupter of the negative pole of the potentiostat. AI8 and AI9 of the data collector; AI GND 3 and AI GND 6 of the data collector are connected together, and then connected to AI9 of the data collector (also can be connected to AI9 after an adjustable resistance); AI0 and AI1 of the data collector are respectively connected to the probe long-term reference electrode leads and portable reference electrodes, and the USB interface of the data collector is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com