Circular high-voltage connector in threaded connection

A high-voltage connector and threaded connection technology, applied in the direction of the base/housing, can solve the problems of no high-voltage connectors, etc., and achieve the effects of high working voltage, good oil resistance and voltage resistance, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings:

[0042] For the purpose of clearly explaining the problem, the attached state of the plug and the socket in the connector is not shown in the accompanying drawings.

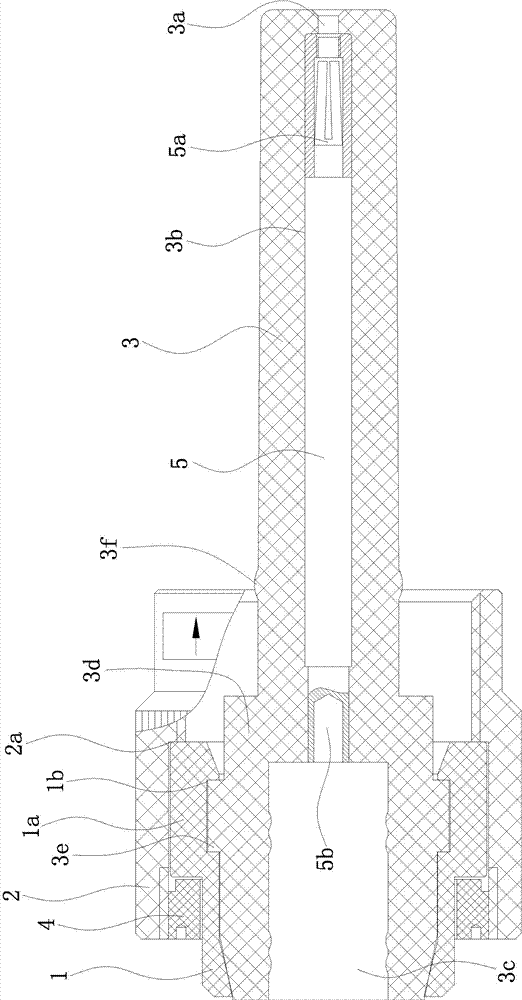

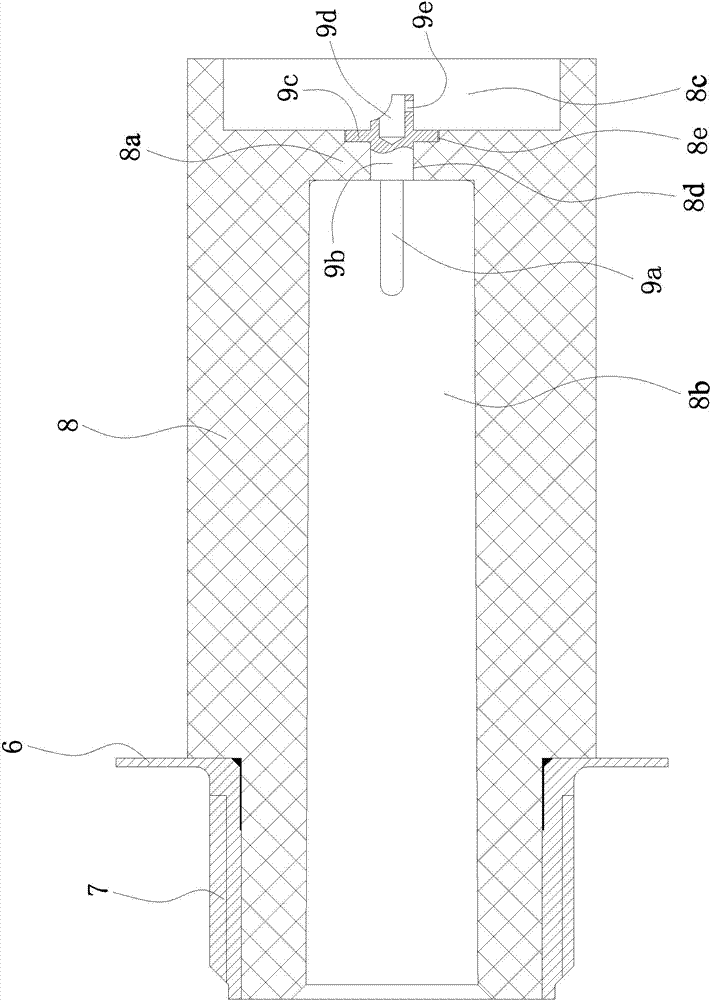

[0043] see figure 1 , figure 2 :

[0044] This connector consists of a plug and a socket.

[0045] The structure of the plug itself and the connection between parts are as follows:

[0046] The plug includes a horizontally arranged and coaxial plug housing 1, a connecting sleeve 2, a circular plug installation tube 3, a plug baffle 4, and a jack contact 5 ( figure 1 not shown in the plug lead described).

[0047] The front side of the plug housing 1 is provided with a circular first boss 1a, and the front side of the inner hole of the plug housing 1 has a circumferential recess 1b.

[0048] Both the front side and the rear side of the connecting sleeve 2 are formed with internal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com