Variable frequency speed regulating method for multiple water injection pumps in oilfield water injection station

A technology of variable frequency speed regulation and oilfield water injection, which is applied in the direction of single-network parallel feeding arrangement, electrical components, control systems, etc., and can solve problems such as energy loss, mismatch between water injection volume and water injection pump displacement, and large return flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

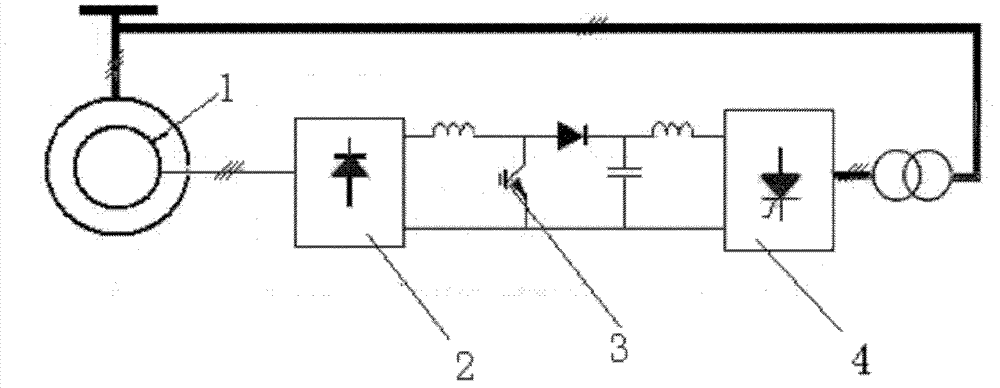

[0012] The frequency conversion speed regulation system of the water injection pump of the oil field water injection station according to the present invention is composed of a winding motor and a rotor frequency conversion control system; The rotor winding 1 of the wire motor is connected, the rectifier 2 is connected in series with the DC chopper 3 and the inverter 4 in sequence, and the inverter 4 is used to return to the transmission network. When there are multiple wound-type motors, the rotor winding 1 of each wound-type motor is connected in series with the rectifier 2 and the series DC chopper 3 in turn, and then connected to the same inverter 4, and is returned to the transmission network through the inverter 4 .

[0013] When the dispensing amount is less than the design capacity of a single water injection pump, the motor operates at the rated state, and only part of the input power is effective. Through the "one-to-many" rotor frequency conversion speed regulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com