Front underfloor structure of vehicle

A vehicle and floor technology, applied to vehicle parts, upper structure, upper structure sub-assembly, etc., can solve problems such as improvement of aerodynamic performance, decrease of lift coefficient, increase of air resistance coefficient, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] First, the configuration will be described.

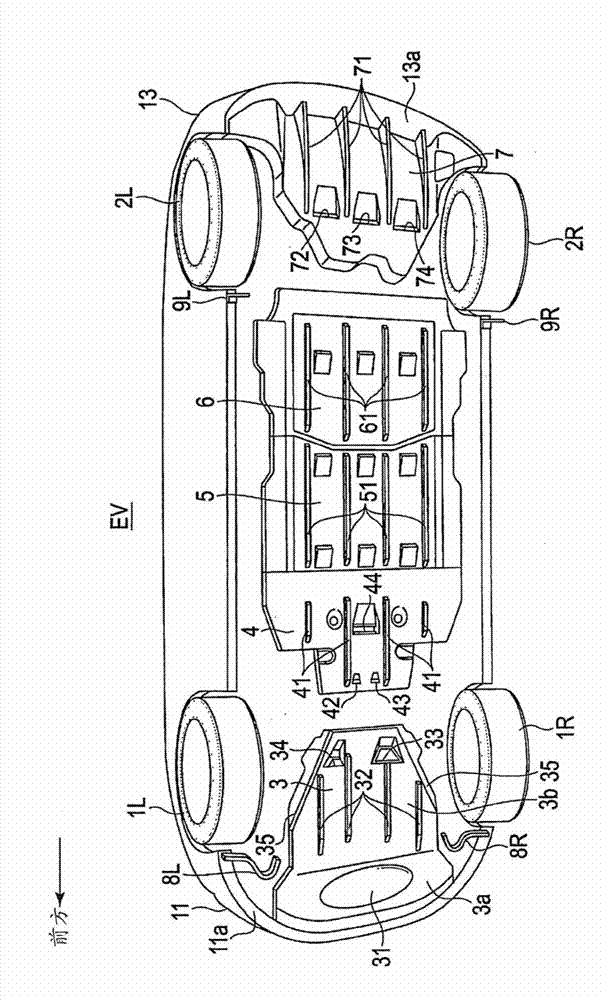

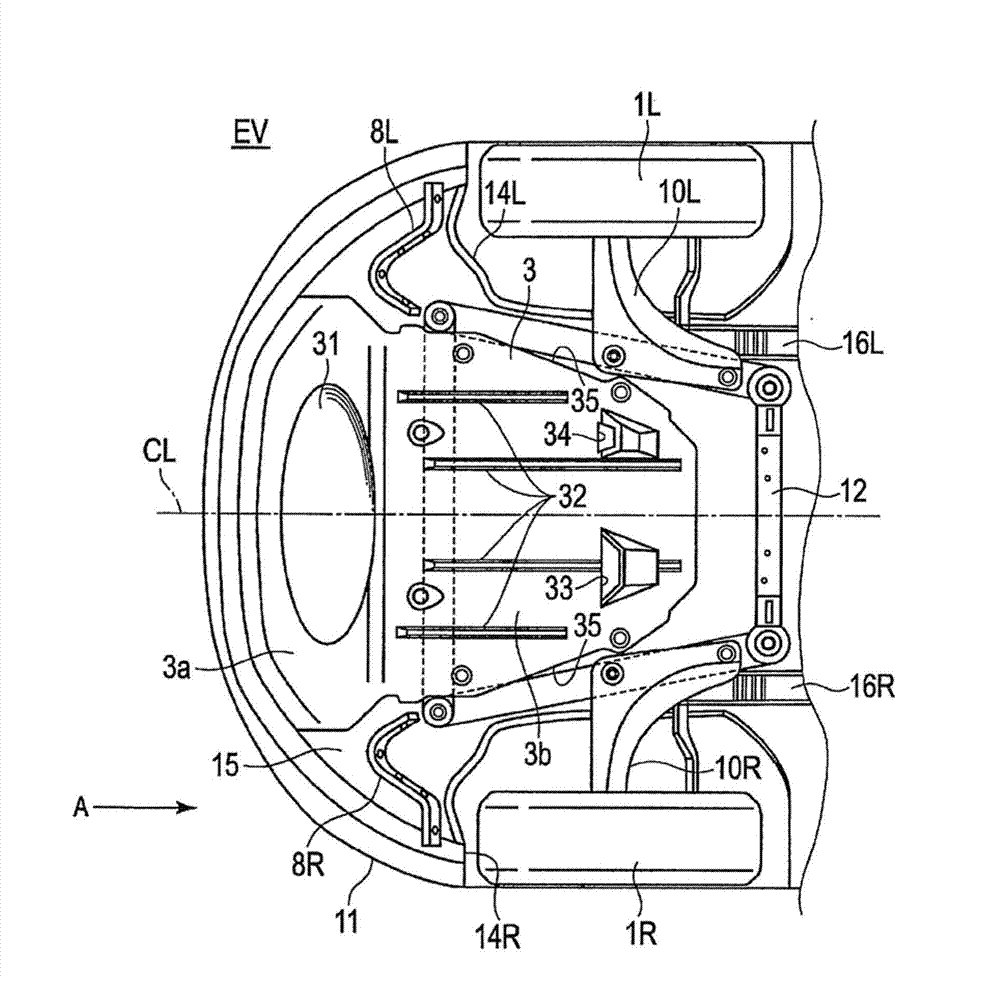

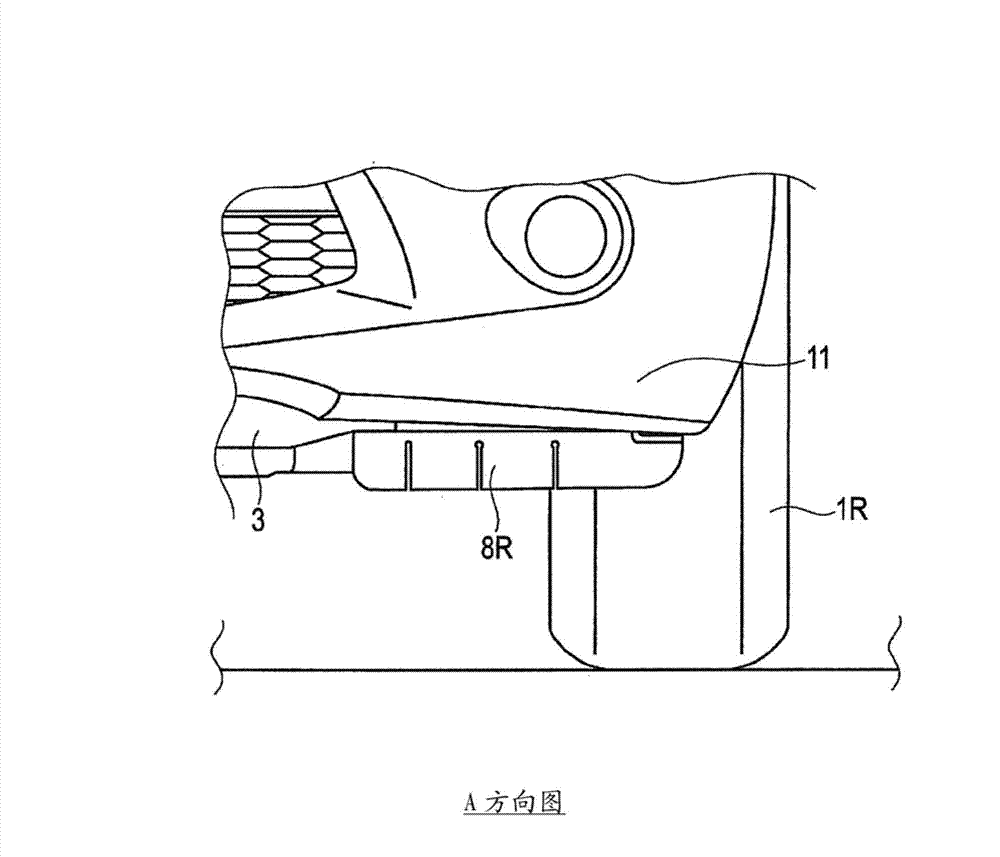

[0056] figure 1 It is a perspective view showing the entire underfloor structure of an electric vehicle (an example of a vehicle) to which the front underfloor structure of the first embodiment is applied. Below, based on figure 1 The overall underfloor structure will be described.

[0057] Such as figure 1 As shown, the overall underfloor structure of the electric vehicle EV in Embodiment 1 includes: a pair of left and right front wheels 1L, 1R, a pair of left and right rear wheels 2L, 2R, a front lower cover 3, and a motor room rear lower cover 4 , the first battery lower cover plate 5, the second battery lower cover plate 6, the rear lower cover plate 7, the left and right pair of front deflectors 8L, 8R, the left and right pair of rear deflectors 9L, 9R.

[0058] The left and right pair of front wheels 1L, 1R are steering wheels and driving wheels, and are connected via front suspension links 10L, 10R (refer to fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com