Device and method for creating a fine-grained fuel from solid or paste-like raw energy materials by means of torrefaction and crushing

A technology of roasting and energy, applied in the field of roasting

Inactive Publication Date: 2012-12-12

ТІССЕНКРУПП УДЕ ҐМБГ +1

View PDF6 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Thus, in the above examples from the prior art, crushing or grinding inevitably requires an additional process step and thus additional mechanical

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

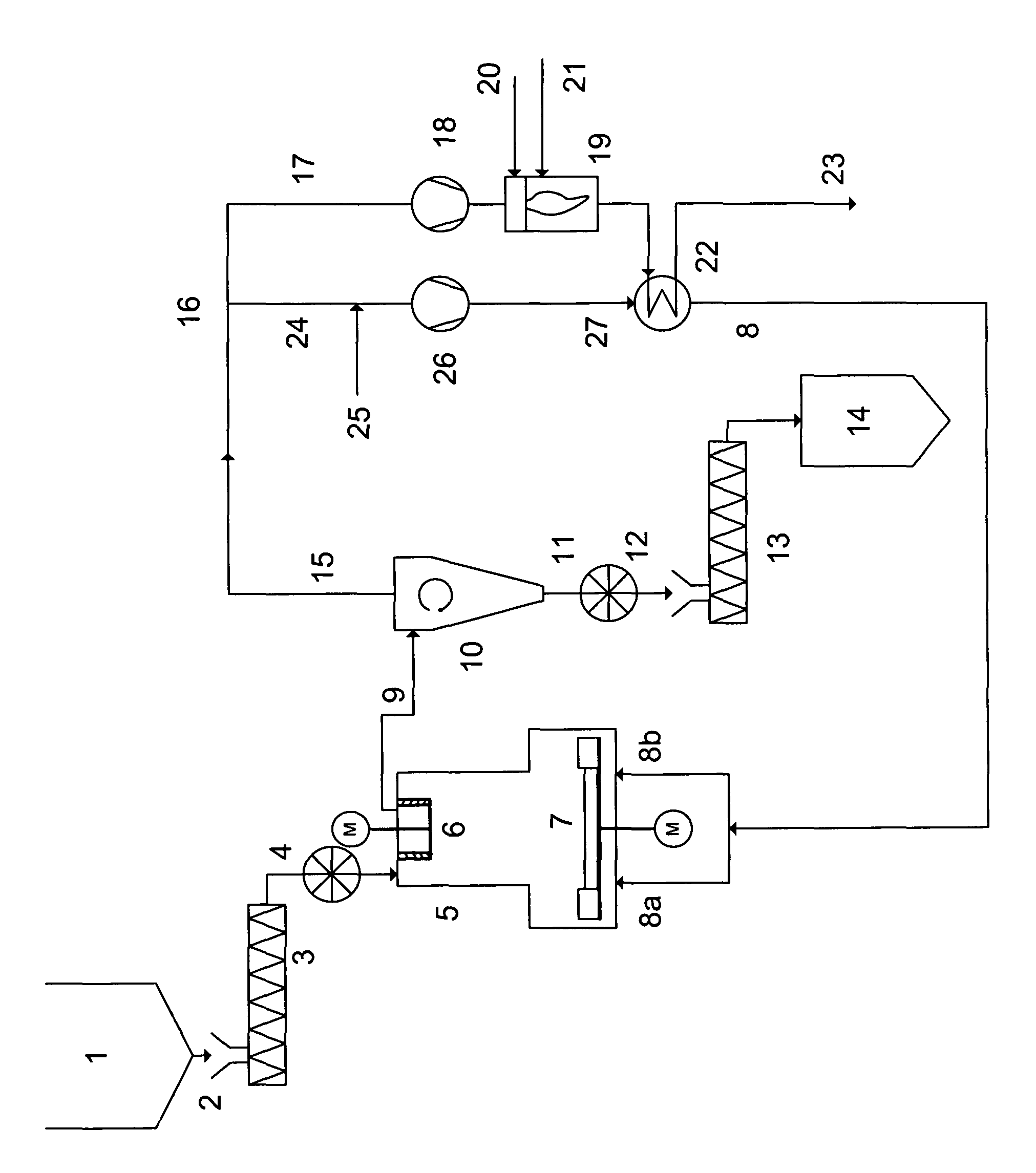

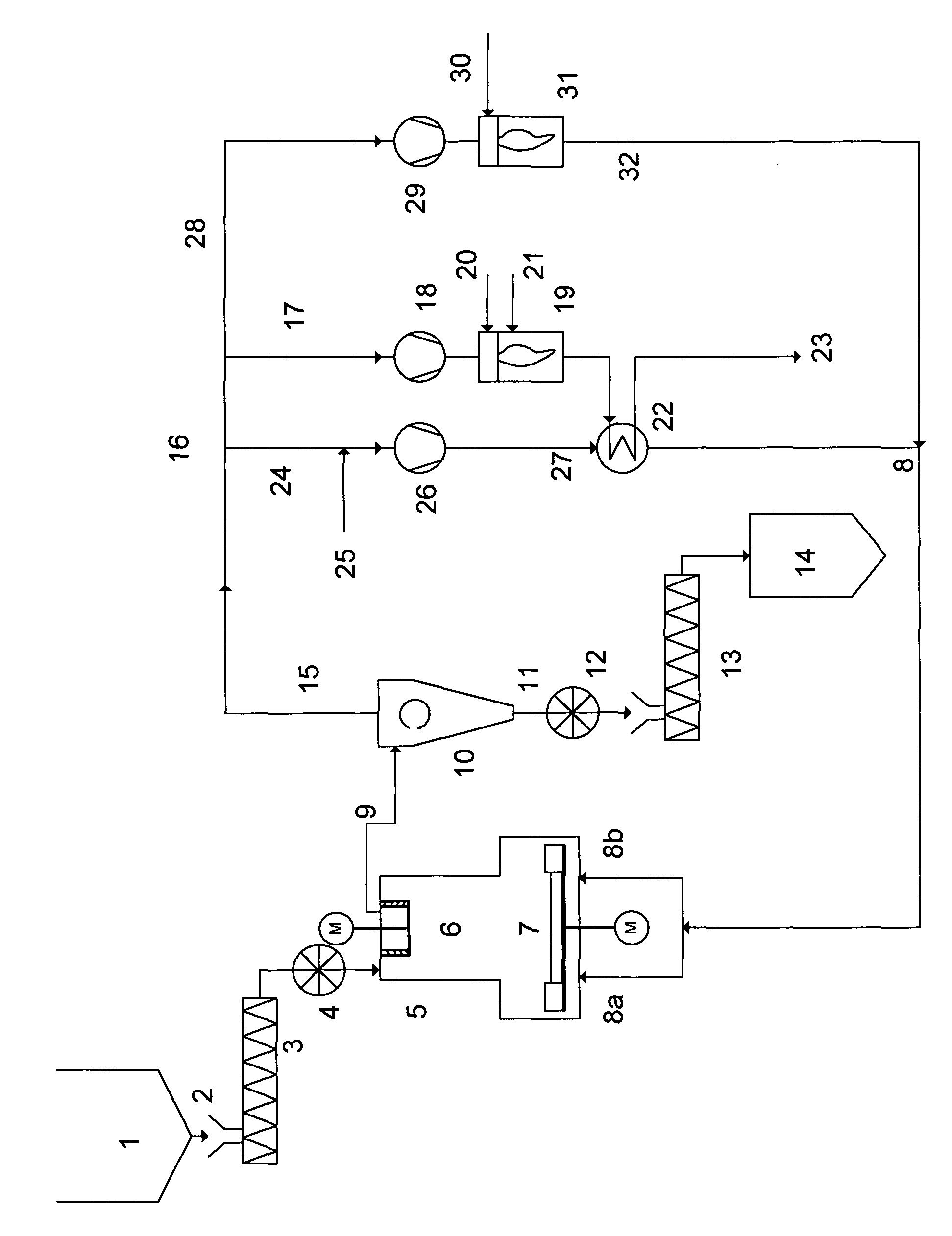

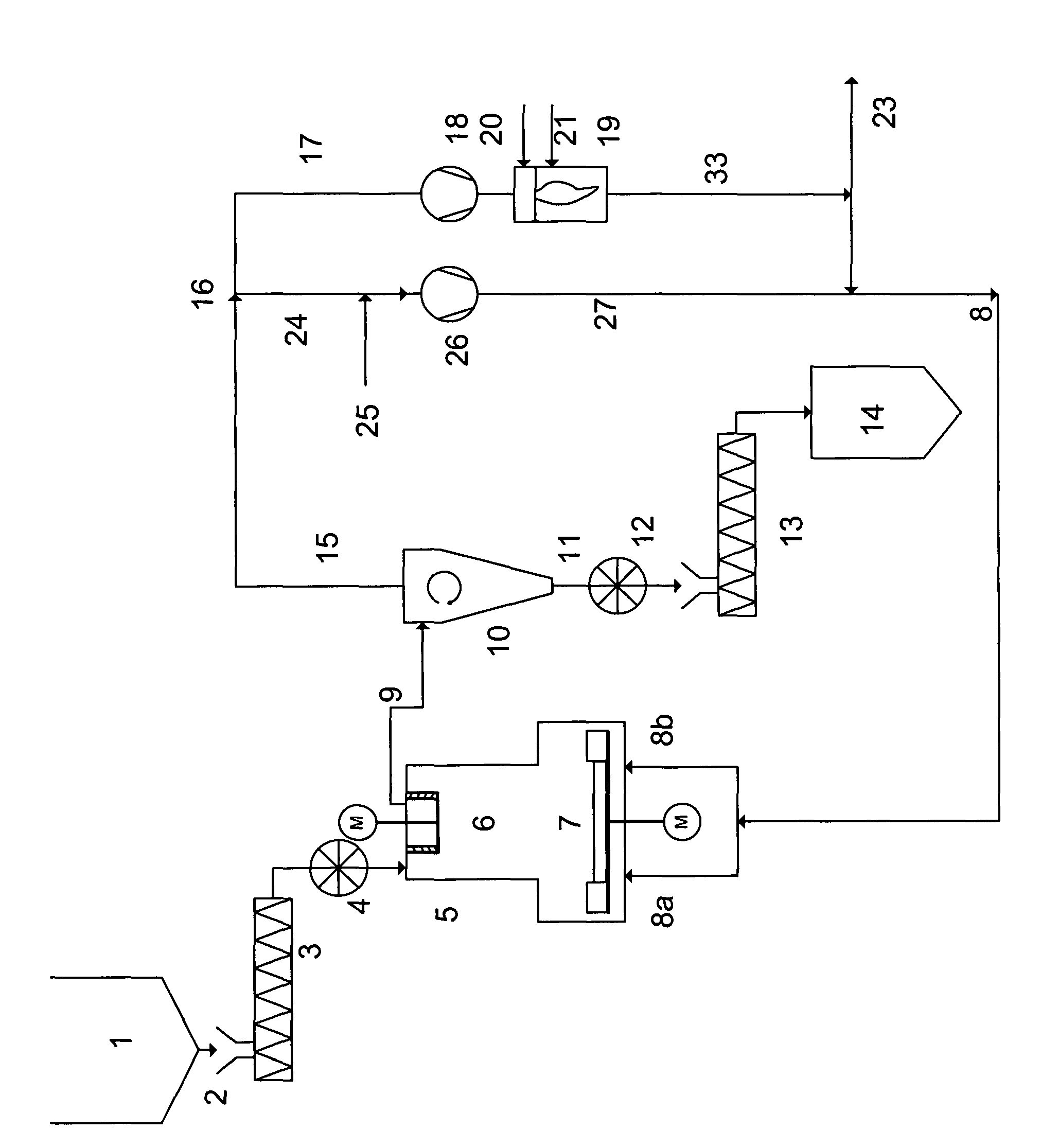

The invention relates to a device and method for creating a fine-grained fuel from solid or paste-like raw energy materials by means of torrefaction, comprising an impact reactor having a rotor and impact elements which is temperature resistant up to 350 degrees Celsius, a feed device for hot circulation gas in the lower region of the impact reactor, a feed device for solid or paste-like raw energy materials in the head region of the impact reactor, at least one withdrawal device for a gas flow comprising comminuted and torrefacted raw energy particles and a separation and withdrawal device for crushed and torrefacted raw energy particles from the gas flow taken out of the impact reactor.

Description

technical field [0001] The present invention relates to the thermal pretreatment, ie torrefaction, of solid fuels containing carbon and hydrogen in an impactor reactor. In the following, said fuels (which may also have a pasty or viscous consistency) are referred to as solid or pasty energy feedstocks and include, for example, biogenic and other highly reactive fuels, fossil fuels and residues. Pastes refer to all materials comprising a mixture of solid and liquid components, examples being sludge and water-based or solvent-based industrial residues or energy-containing liquids such as oily substances or lubricants. There is a general drive to develop the use of renewable energy and to recycle waste and residues, where thermal gasification allows particularly efficient utilization from an energy and material point of view. Entrained bed gasification is particularly advantageous, the plants for which are usually of great capacity and also run on coal. The invention also enabl...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10L5/44

CPCC10L5/44C10J2300/0903C10J3/482C10L9/083Y02E50/30Y02E50/15C10J2300/16Y02E50/14C10B49/02Y02E50/10C10B53/02Y02P20/129

Inventor 拉尔夫·阿伯拉罕斯蒂芬·海莫尔拉尔夫·舍费尔

Owner ТІССЕНКРУПП УДЕ ҐМБГ

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com