Method of operating a metering pump and apparatus having a metering pump

A technology for metering pumps and equipment, which is applied in the direction of mechanical equipment, pumps, pump control, etc., and can solve problems such as changes in the operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

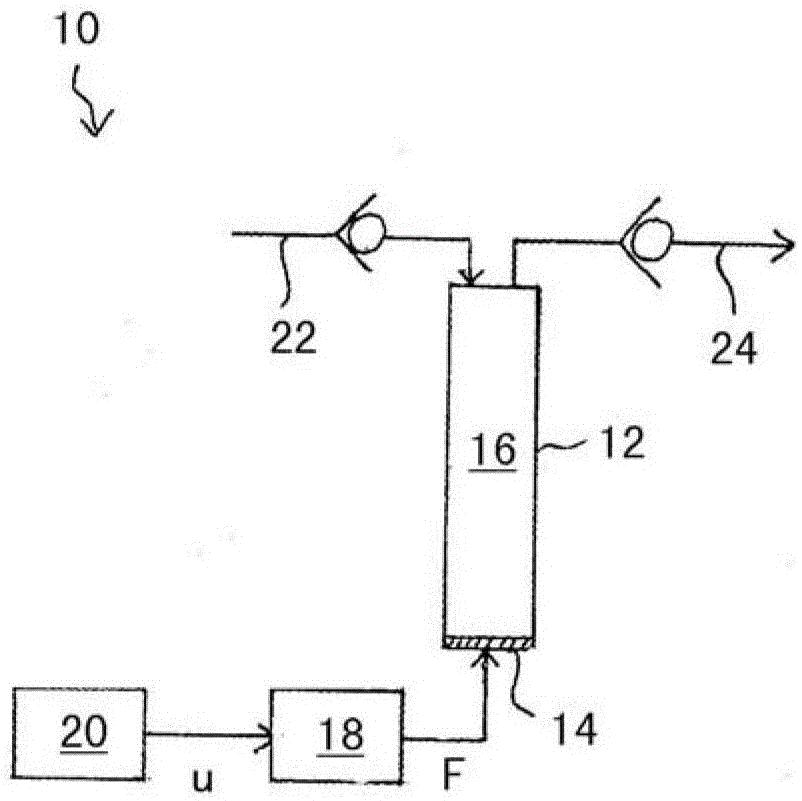

[0034]FIG. 1 schematically shows an example of a device 10 for pumping a liquid, for example fuel, from an inlet line 22 to an outlet line 24 by means of a metering pump 12 . The metering pump 12 includes a housing and a piston 14 defining a pump chamber 16 together with the housing. The current position of the piston 14 relative to the housing defines the current volume of the pump chamber 16 . FIG. 1 shows the piston 14 in an initial position in which the pump chamber 16 assumes its maximum volume.

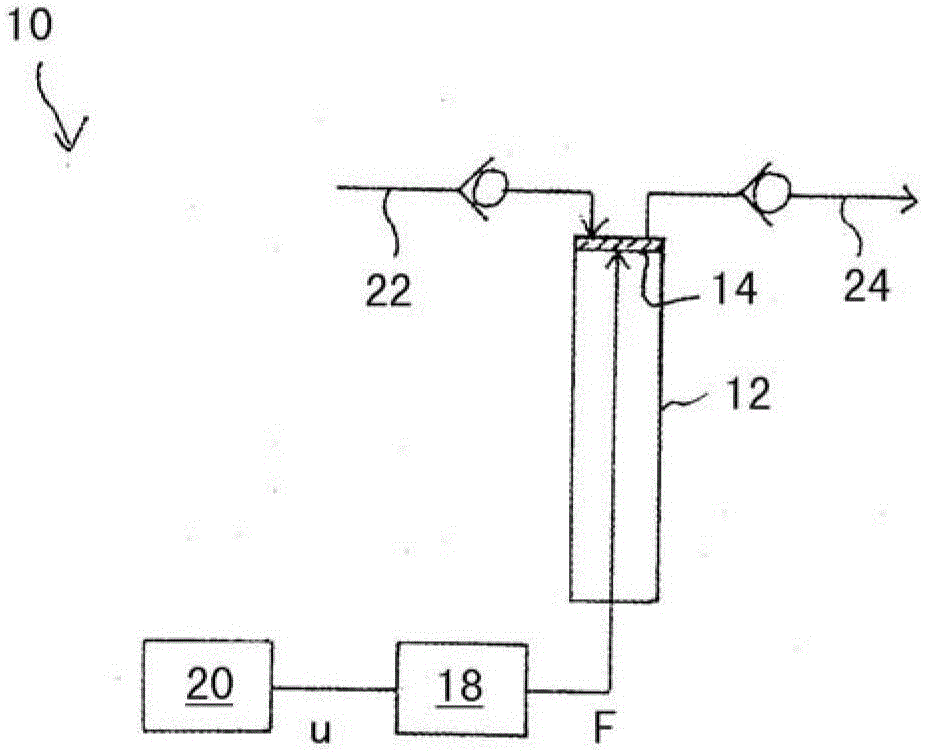

[0035] FIG. 2 shows the piston 14 in the end position in which the volume of the pump chamber 16 is zero. The piston 14 is connected to an electric drive unit 18 . The drive unit 18 is adapted to cyclically or periodically apply a force F to the piston 14 to move the piston 14 back and forth between its starting position and its end position. The metering pump 12 can have a spring (not shown) which returns the piston 14 from the end position to the start position without the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com