Aviation Gas Helical Rotary Engine

A jet engine and solenoid technology, applied in engine components, machines/engines, non-variable engines, etc., can solve the problems of not being able to take off in time, occupying space and tonnage of the aircraft carrier, complex structure, etc., and achieve long service life , improve reliability, overcome the effect of overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The specific implementation manners of the present invention will be further described in detail below.

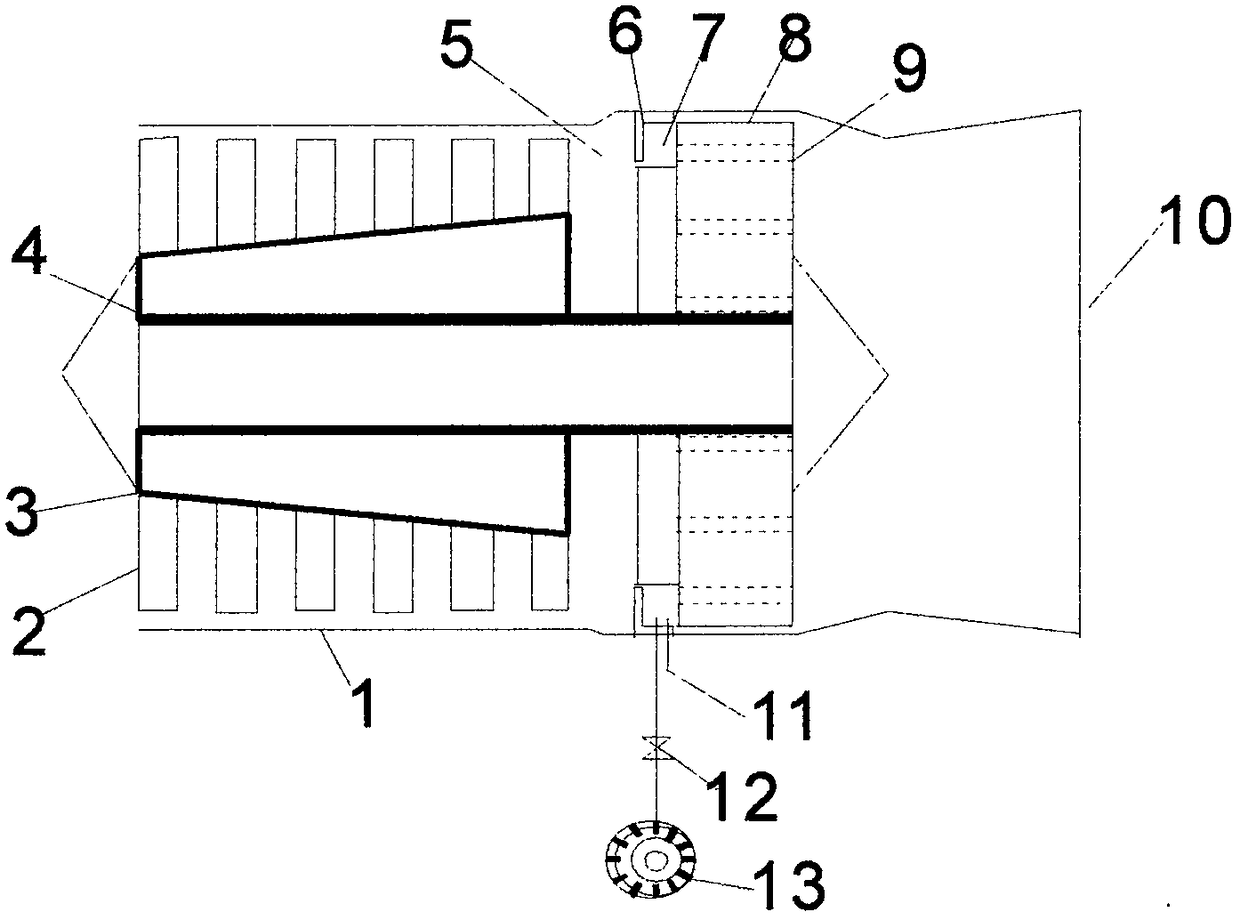

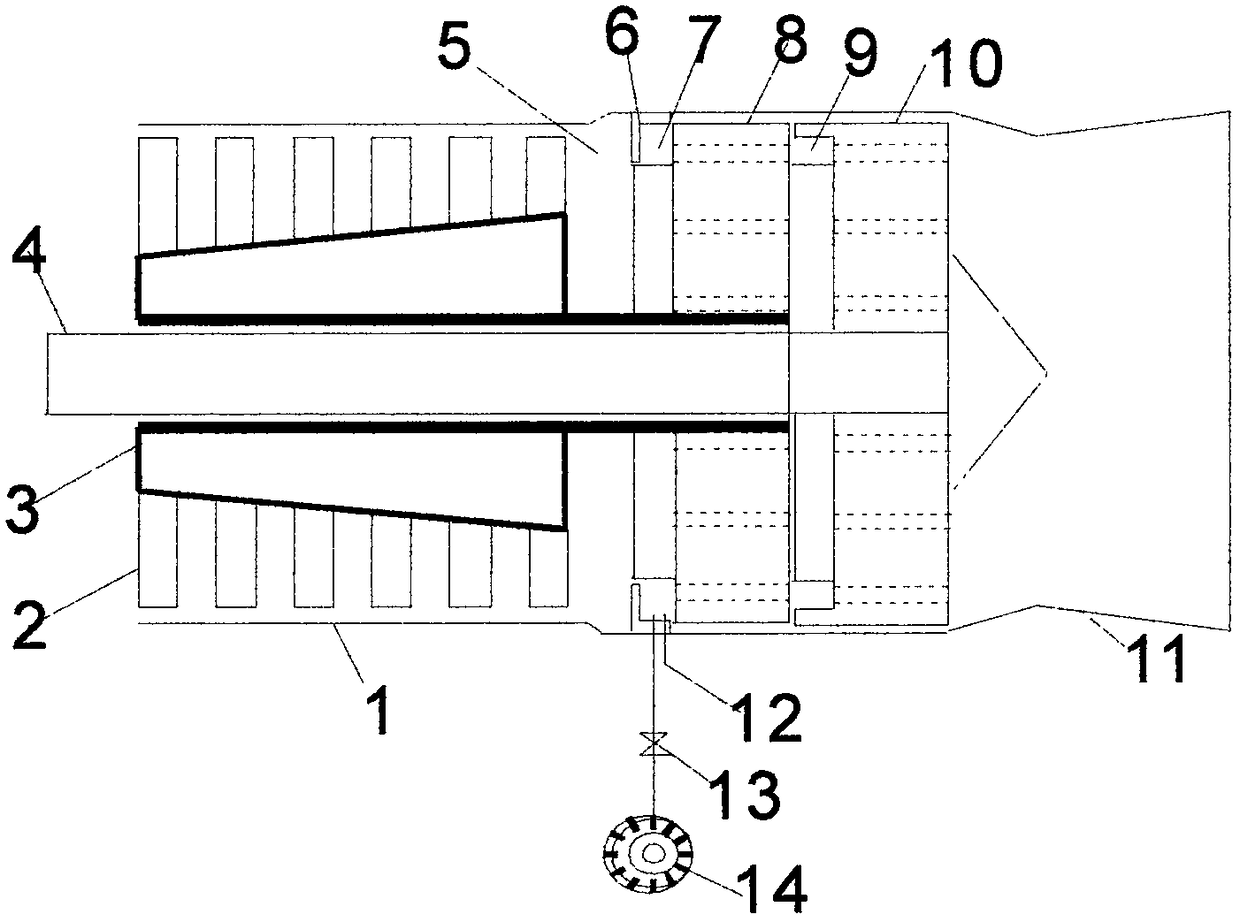

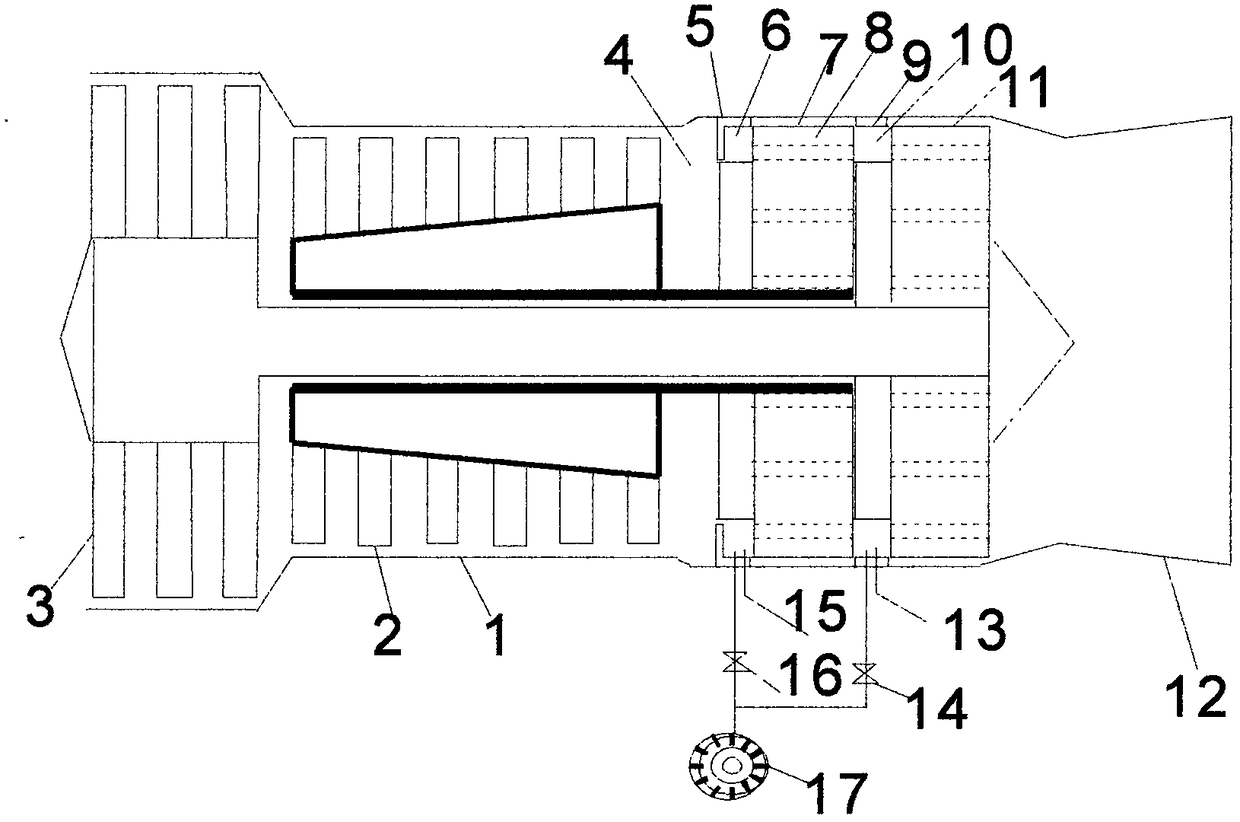

[0061] A gas-fired helical rotor jet engine, including a turbojet engine, uses a stepped helical rotor instead of a turbine, and a diffuser is arranged between the exhaust port of the compressor and the stepped helical rotor, and is fixed on the casing in an L-shaped can The combination of the annular channel for adjusting the air volume and the steps of the spiral tube rotor constitutes the first annular combustion chamber. The annular combustion chamber is equipped with at least one fuel injection device and an ignition device. The damper of the annular channel can control the amount of compressed air entering the first combustion chamber and the amount of compressed air flowing through the annular channel around the spiral tube rotor. This mechanism constitutes a gas generator, and the high-speed flowing air is decelerated by the diffuser during operation. The hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com