Compressed air auxiliary device and control method for supercharged internal combustion engine

A technology of compressed air and auxiliary devices, applied in electrical control, engine control, fuel injection control, etc., which can solve problems such as the increase in the amount of harmful substances, the deterioration of the economy and emissions of internal combustion engines, and the inability of the intake air of internal combustion engines to meet the combustion requirements. The effect of efficient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

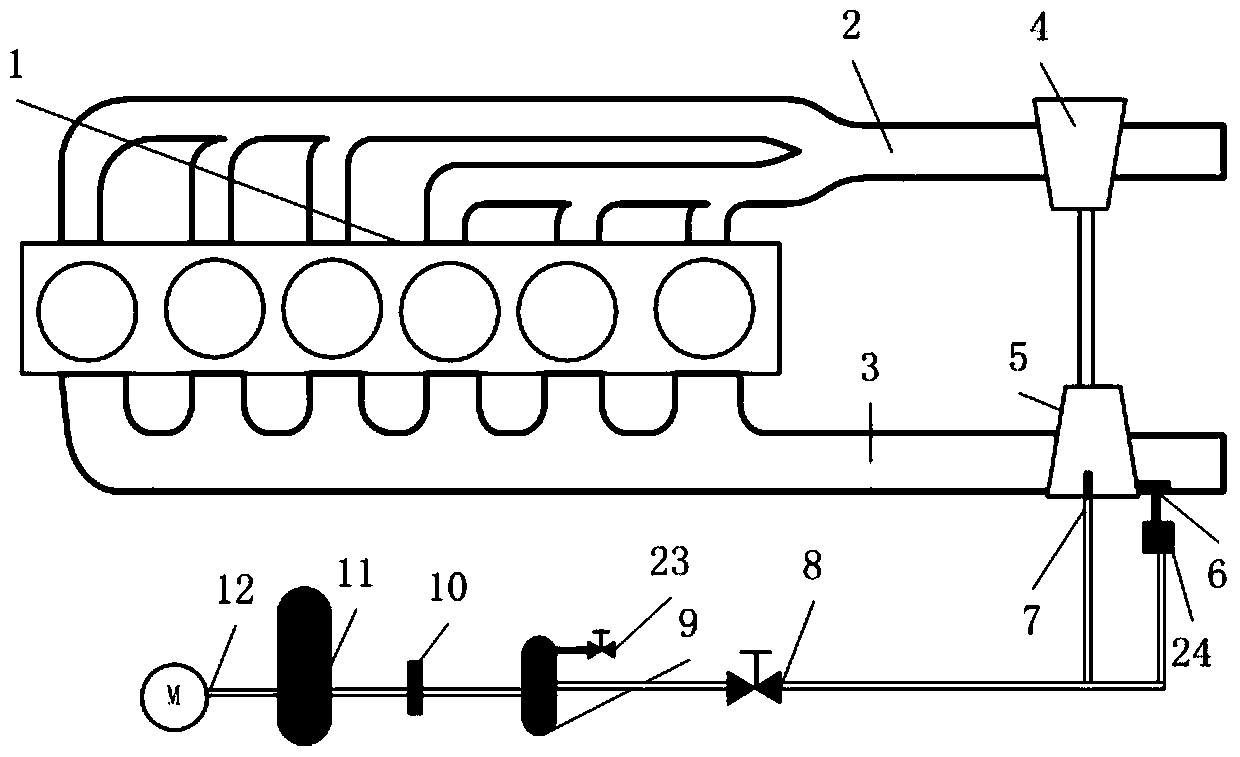

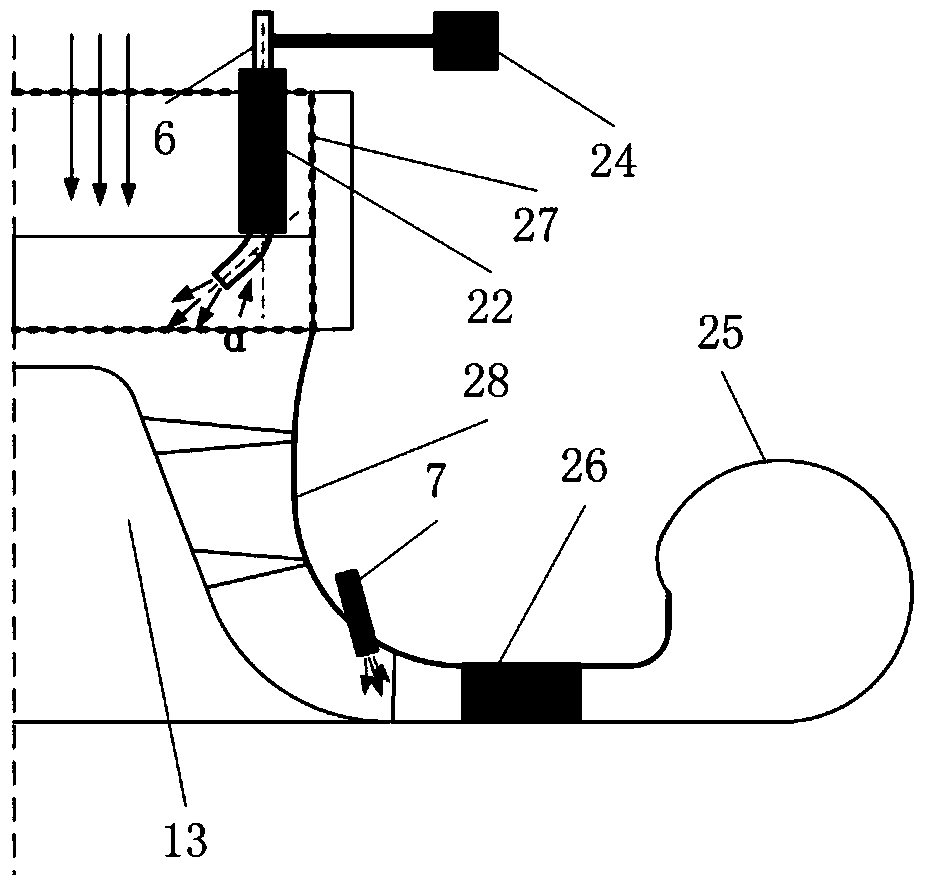

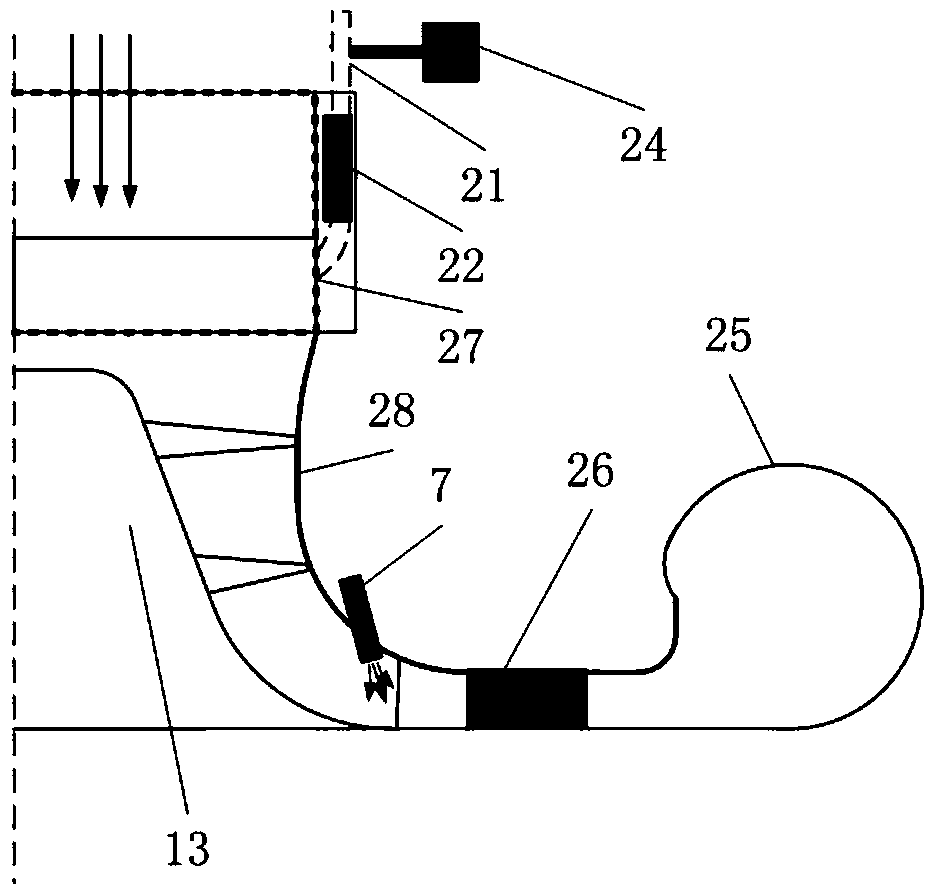

[0026] combine Figure 1 to Figure 4 A detailed description of the compressed air auxiliary device of a supercharged internal combustion engine of the present invention:

[0027] The overall structure of the compressed air auxiliary device of the present invention is as attached figure 1 As shown, the specific installation method of the compressor is as follows figure 2 , 3 shown. The device can be used for any supercharged internal combustion engine including a supercharged diesel engine and a supercharged gasoline engine, and meanwhile, the device can also be applied to a vehicle internal combustion engine and a marine internal combustion engine. The compressed air auxiliary device includes: an air source device, a pressure regulating device and an air injection device.

[0028] The present invention is applied to a supercharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com