Semiconductor element and its manufacturing method

A semiconductor and component technology, applied in the field of high-voltage semiconductor components and their manufacturing, can solve the problems of snapback breakdown, component reliability and service life reduction, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

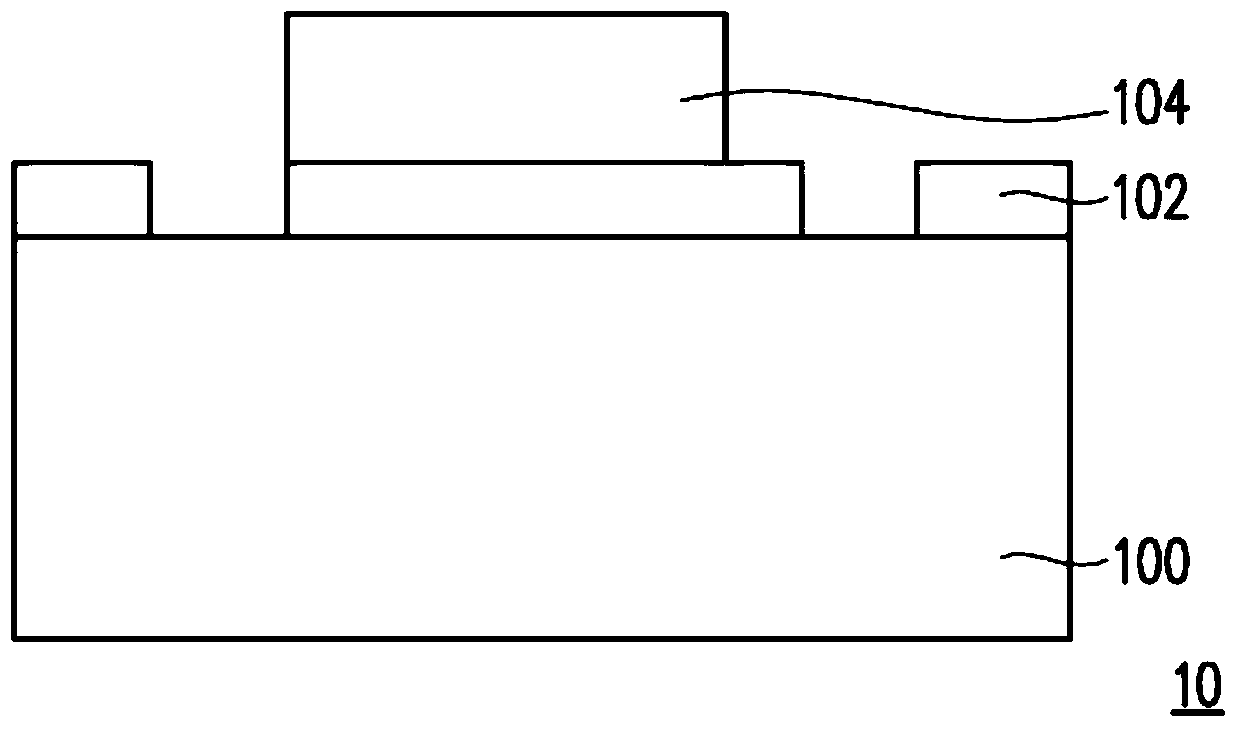

[0061] An experimental example of a semiconductor device fabricated according to an embodiment of the present invention is simulated. In this experimental example, the substrate of the semiconductor element includes a source region and a drain region, the distance between the source region and the drain region is 2.5 μm to 4 μm (ie the second width L2 ), and the gate of the semiconductor element has Two gate doped regions and one gate undoped region, the gate undoped region is located between the two gate doped regions to separate them, and the gate undoped region has a width of 0.2 μm (ie first width L1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com