Method for producing a heat exchanger and heat exchanger

A heat exchanger and structure technology, applied in the direction of heat exchanger fixing, heat exchange equipment, heat sink, etc., can solve the problems of complex structure type, large weight, etc., and achieve the effect of avoiding forced stress, small structure, and optimizing heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

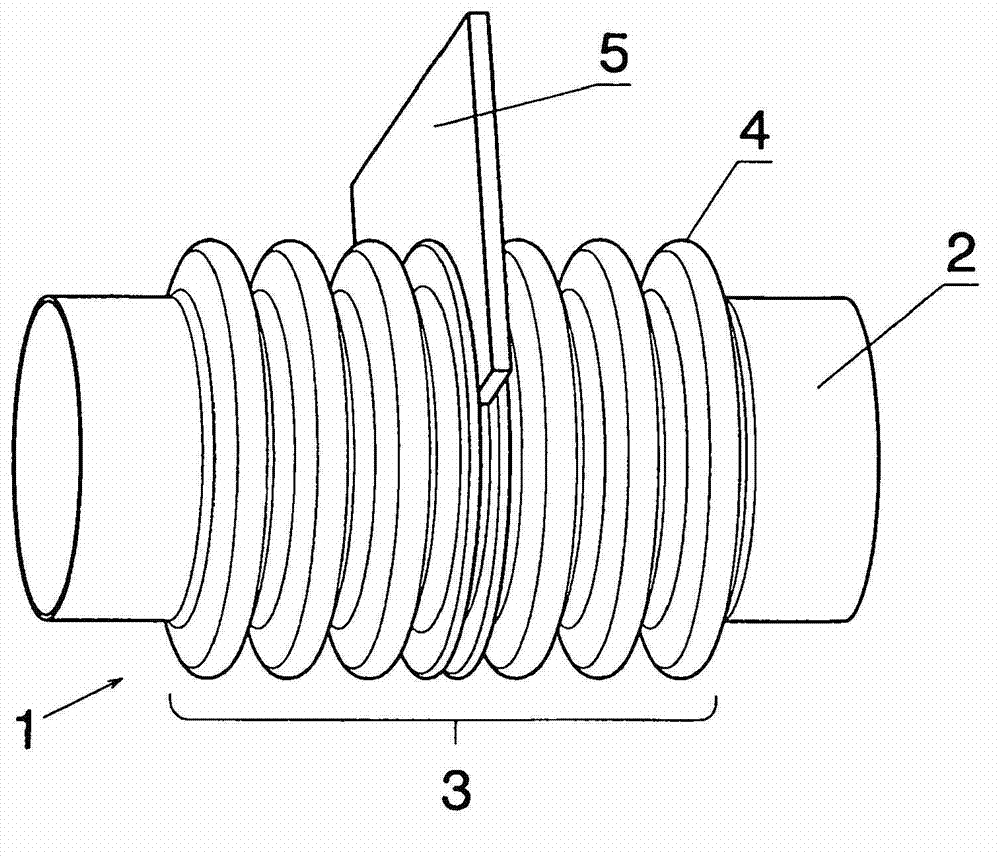

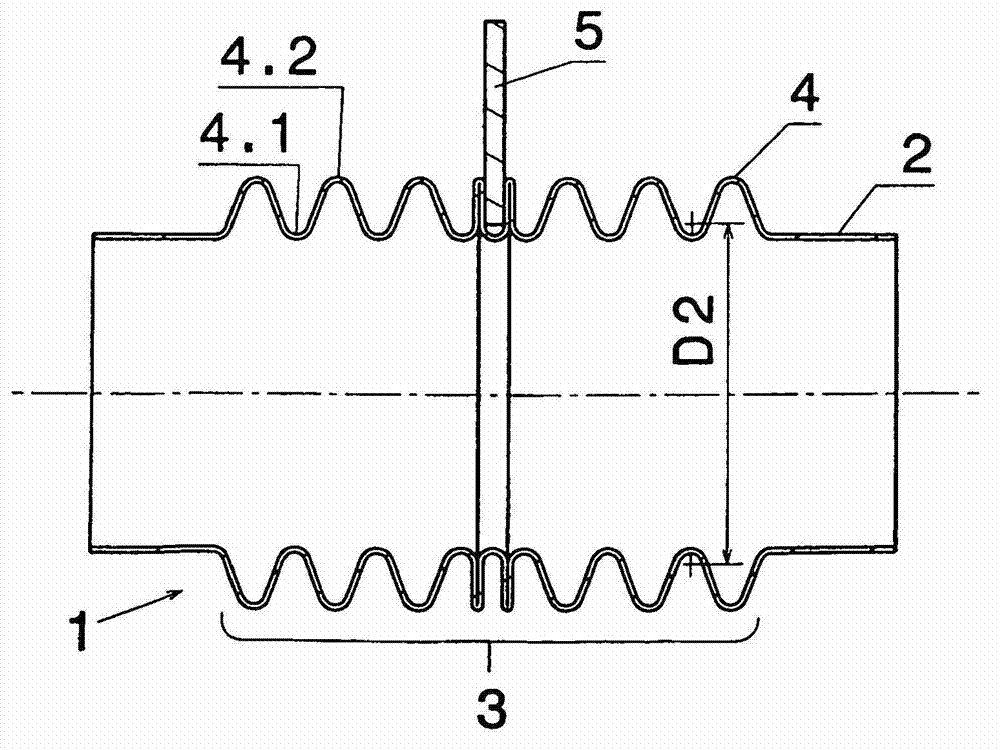

[0016] figure 1 and figure 2 A general view and a side view showing an overview of the heat exchanger 1 according to the invention. The heat exchanger 1 comprises a pipe 2 with bellows 3 . The pipe 2 and the corrugated body 3 are here preferably made of stainless steel and produced in one piece. The corrugated body 3 has corrugations 4 with troughs 4.1 and crests 4.2. The sheet metal 5 is pressed between two corrugations 4 . shown here figure 1 In the exemplary embodiment shown by way of example, a single sheet metal 5 clamped between the corrugations 4 is shown. It is also possible to insert several sheet metals, wherein the sheet metals can be inserted not only from one side, but also from two opposite sides of the pipe and thus point radially in different directions. This can be applied flexibly depending on the space requirements or cooling requirements.

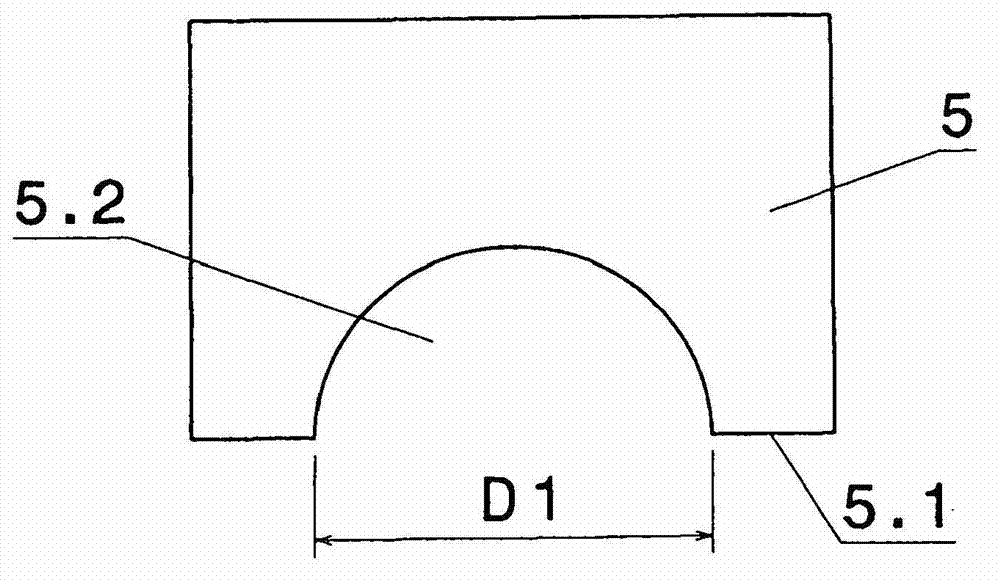

[0017] image 3 Such a sheet 5 is shown. The sheet metal 5 here has a rectangular basic shape, wherein a sem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com