Cold extrusion device, and female die and male die thereof

A technology of cold extrusion and die, applied in the direction of metal extrusion dies, etc., can solve the problems of large product error and complex structure, and achieve the effect of small comprehensive error, simple structure and good product size consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

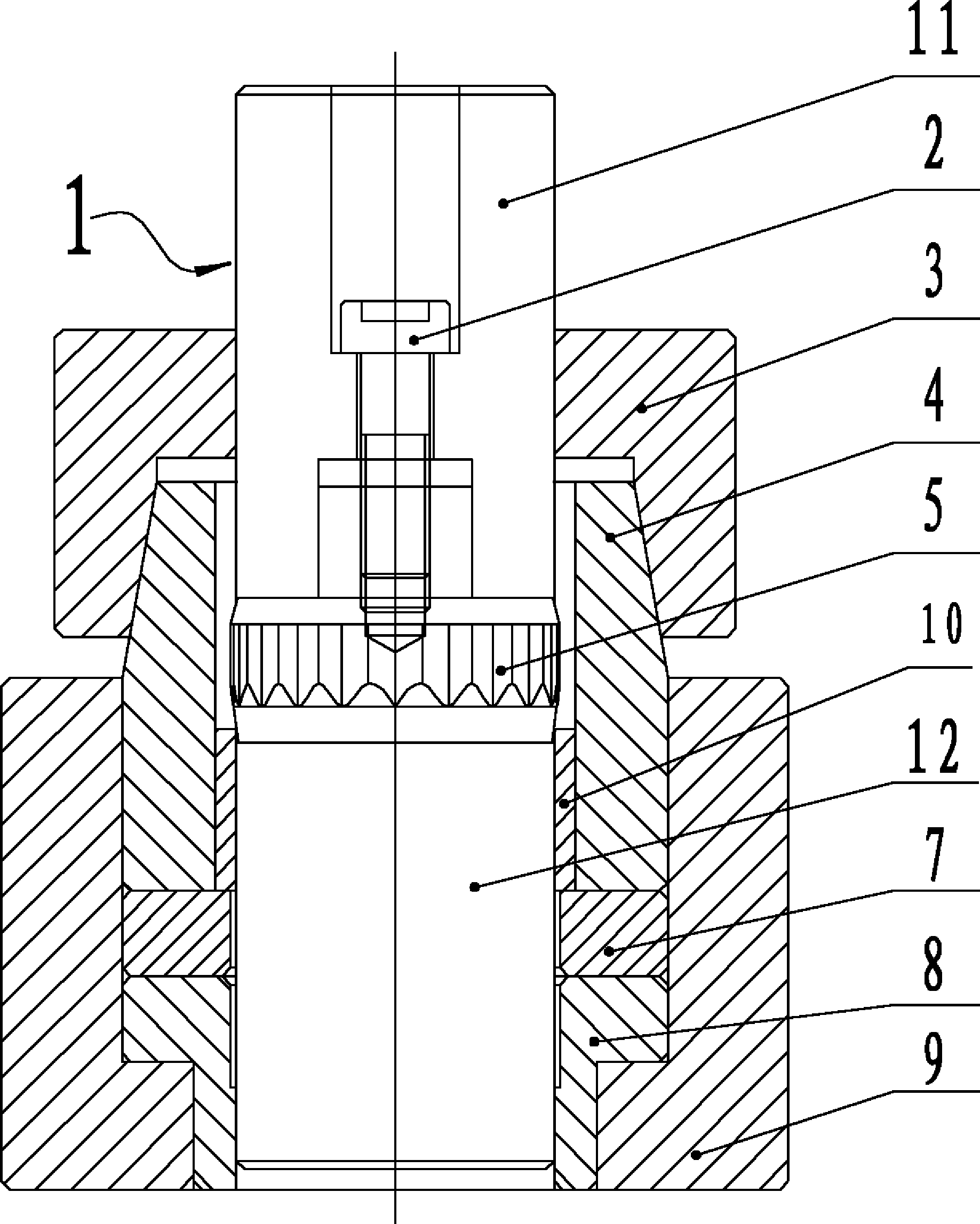

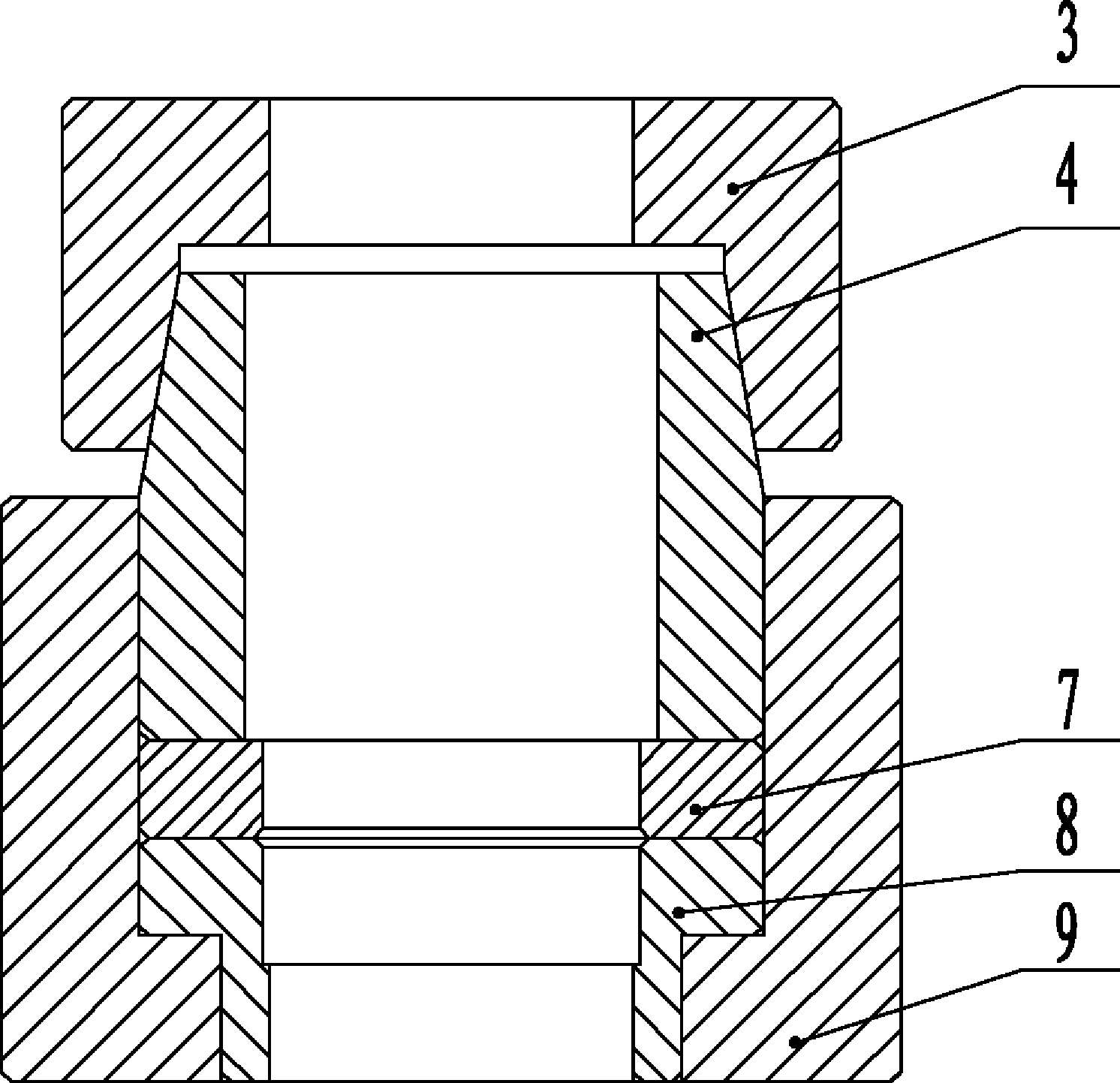

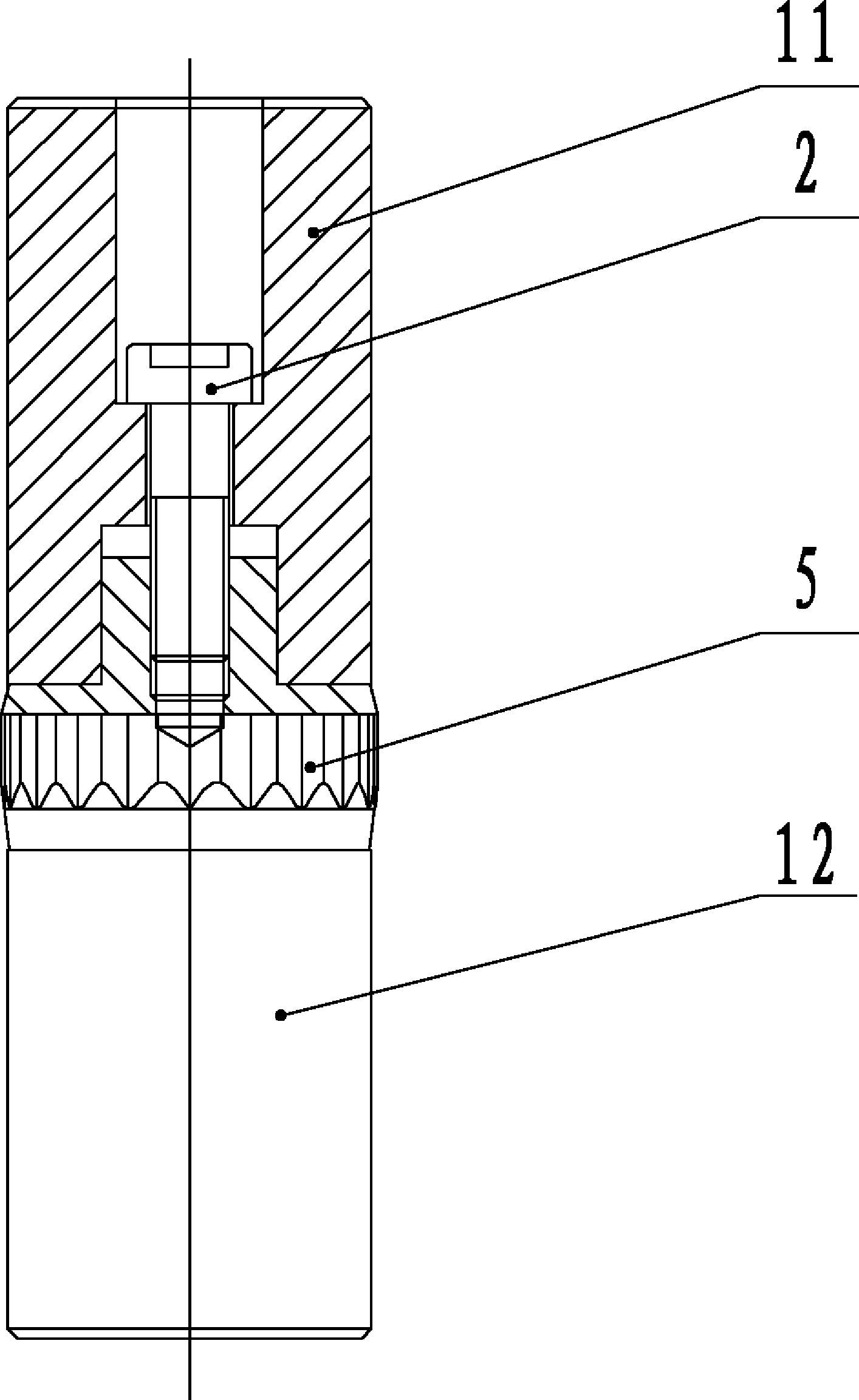

[0022] An embodiment of a cold extrusion device of the present invention, such as figure 1 As shown, it includes a die and a punch. The die includes a die base 9, which has a sleeve-shaped structure. The lower end of the die base 9 is provided with an inward turning edge. The coaxial interference fit in the inner hole is equipped with a lower guide sleeve 8, and the upper end of the lower guide sleeve 8 is provided with an outer expansion edge that overlaps with the said inward turning edge. The upper part of the mold cover 4 is coaxially equipped with a mold cover 4. The inner diameter of the mold cover 4 is equal to the outer diameter of the workpiece. The upper end of the mold cover 4 is detachable and coaxially provided with an upper guide sleeve 3. The matching cylindrical structure, and the upper end plate that closes the upper end opening of the cylindrical structure, the upper end plate is provided with an upper guide hole, the outer peripheral surface of the upper par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com