Cover pressing die of threaded mouth ofglass bottle

A technology for capping molds and glass bottles, applied in the directions of capping, closing, packaging, etc., can solve the problem of not being able to press the cap tightly, and achieve the effect of reducing material costs, reducing the lax sealing of the bottle mouth, and facilitating processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

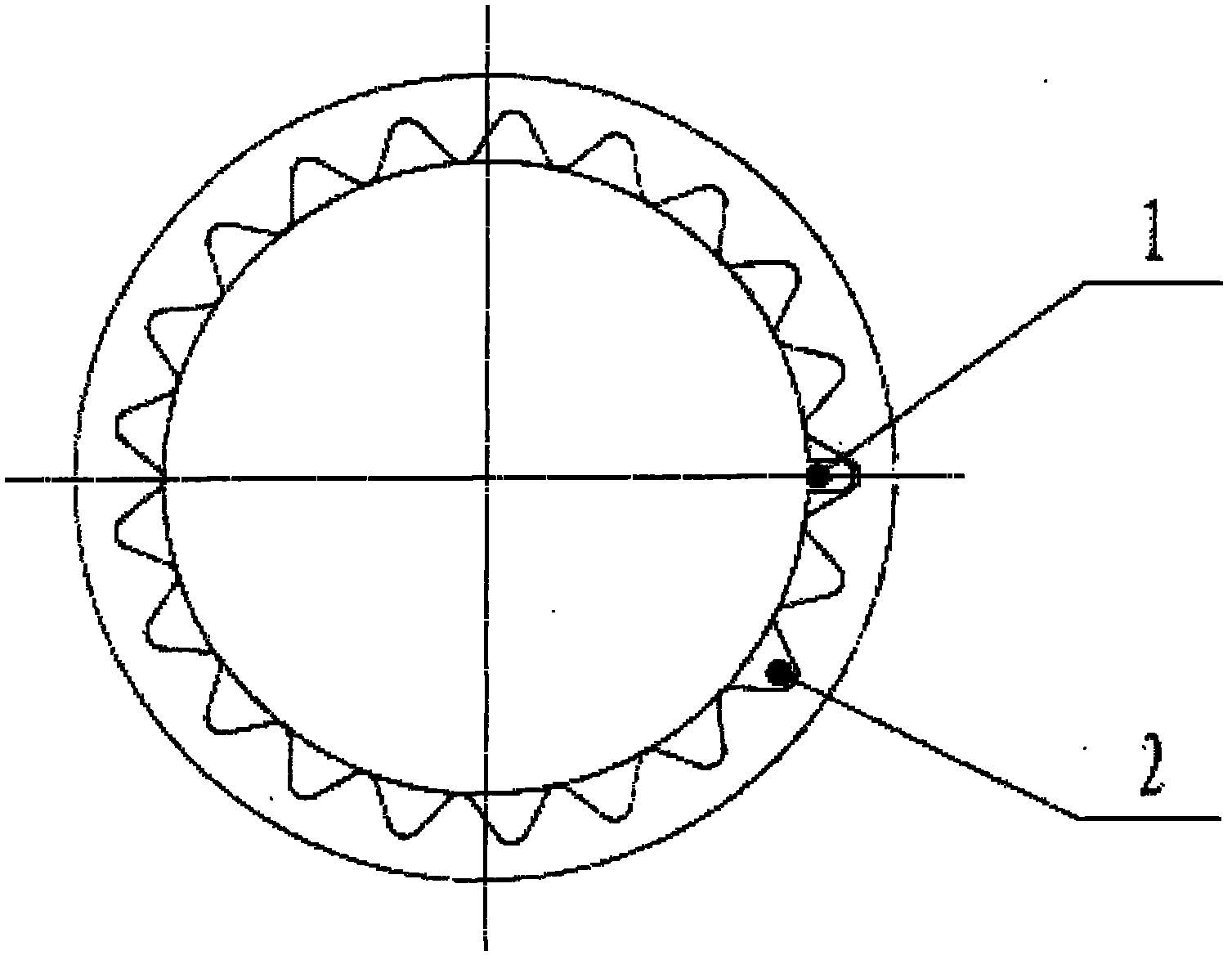

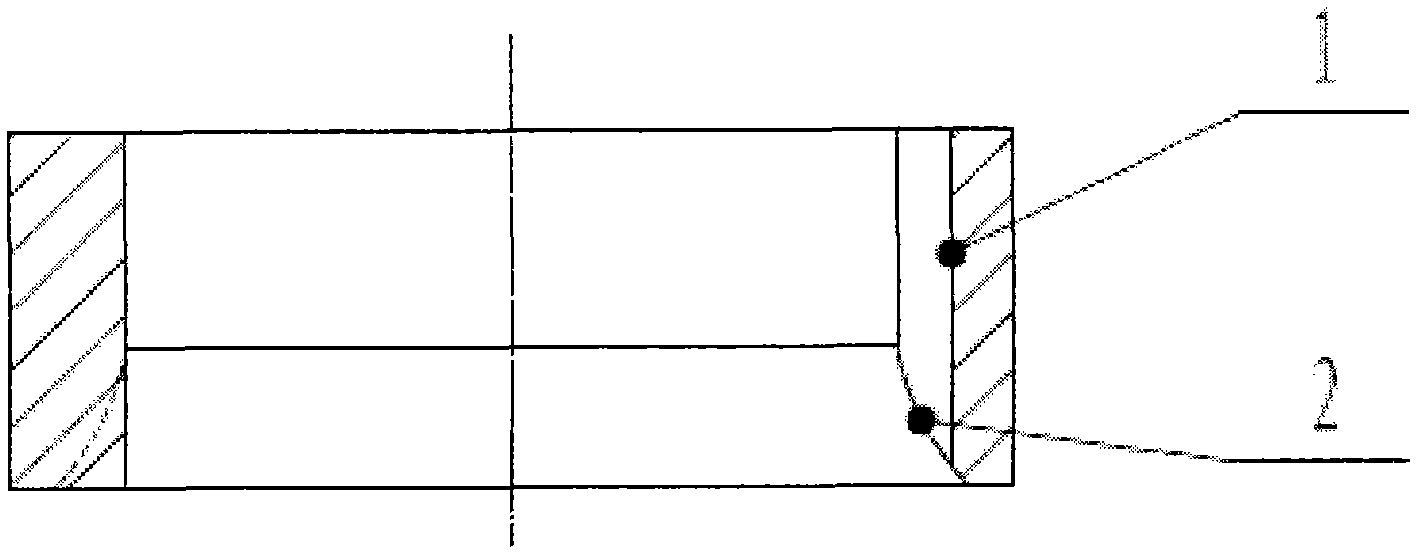

[0012] The present invention is described in detail below with reference to the accompanying drawings.

[0013] The present invention utilizes the structure of the concave arc surface 1 and a gap 2 inside the capping die, so that after the capping die stamps the bottle cap, the bottle cap is sealed in the bottle mouth without damage, and the bottle cap will not be stored in the later stage. The presence of external rust allows people to open bottle caps by hand without using a cap screwdriver, and also allows people to reseal opened screw top glass bottles without any equipment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arc radius | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com