Wire-drawing ceramic processing device and processing method thereof

A ceramic processing and ceramic technology, applied in the field of wire drawing ceramic processing devices, can solve the problems of high energy consumption, simple process, easy scratching, etc., and achieve the effects of high hardness, good toughness, and oxidation-resistant appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

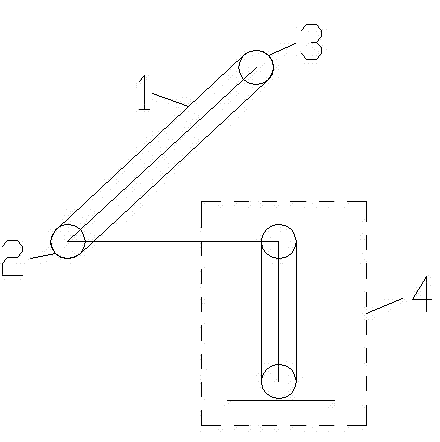

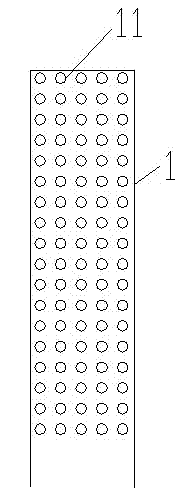

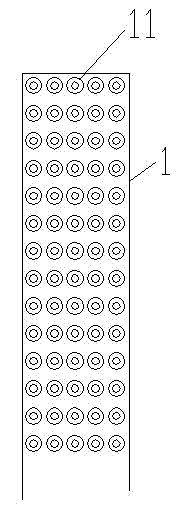

[0021] Such as figure 1 As shown, a wire drawing ceramic processing device includes a driving device 4, a first transmission wheel 2 connected to the driving device 4, a grinding belt 1, a second transmission wheel 3 connected to the first transmission wheel 2 through the grinding belt 1, Wherein, the grinding belt 1 is provided with a grinding structure 11 for grinding the surface of the ceramic product. Through the high-speed rotation of the grinding belt 1, the surface of the ceramic product to be processed is ground with debris, and the processed ceramic product has a certain sense of direction, and has a metallic luster, and the surface of the product will not stick to dirt.

[0022] Further, the material of the grinding belt 1 is a mixture of diamond powder and resin, or a mixture of emery powder and resin, or a mixture of corundum powder and resin, and the ratio of the above mixture can be adjusted according to the hardness of the ceramic. The above-mentioned mixed mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com