Continuous high-speed boxing machine of block type material

A cartoning machine, block technology, applied in packaging, single object, transportation and packaging, etc., can solve the problems of no mechanical memory device, inconvenient replacement of specifications, unstable work, etc., to achieve a wide range of applications, easy installation and maintenance. , the effect of improving the production efficiency of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

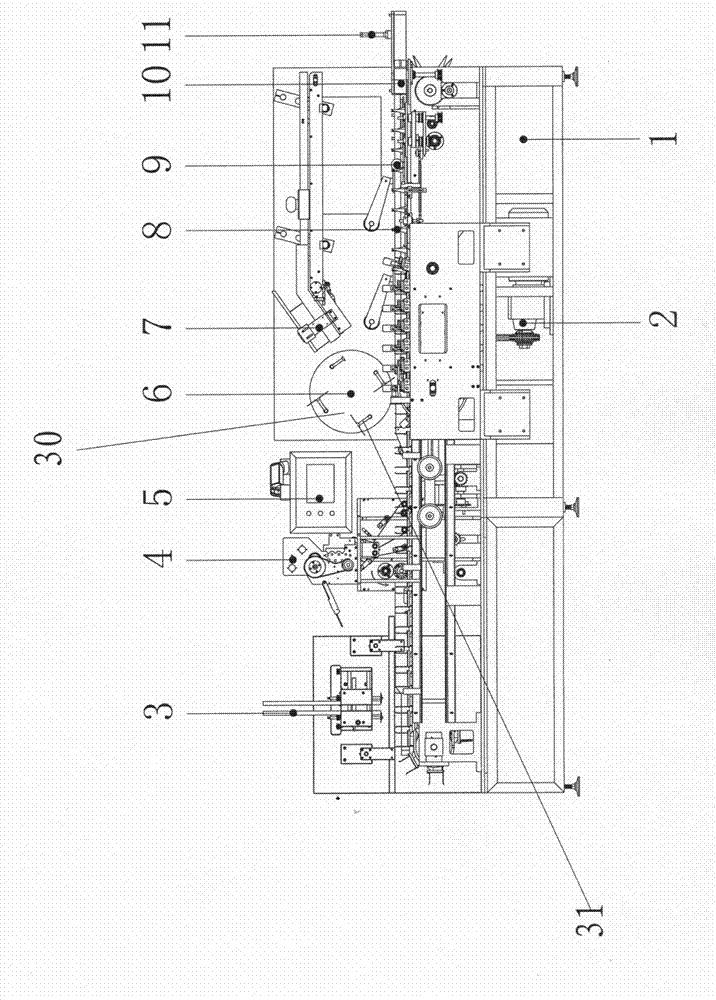

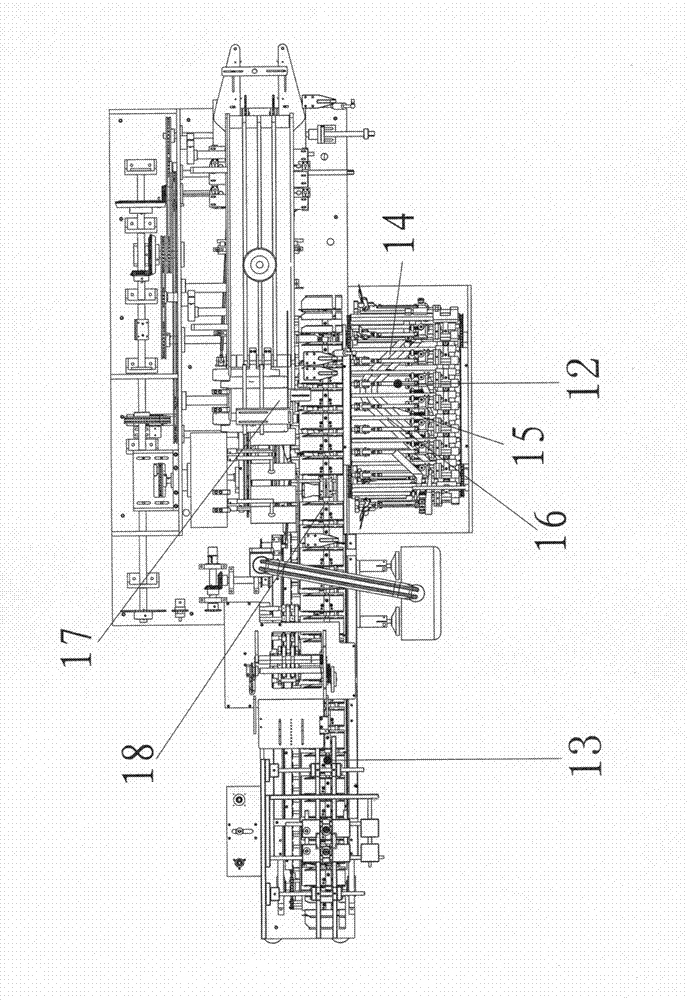

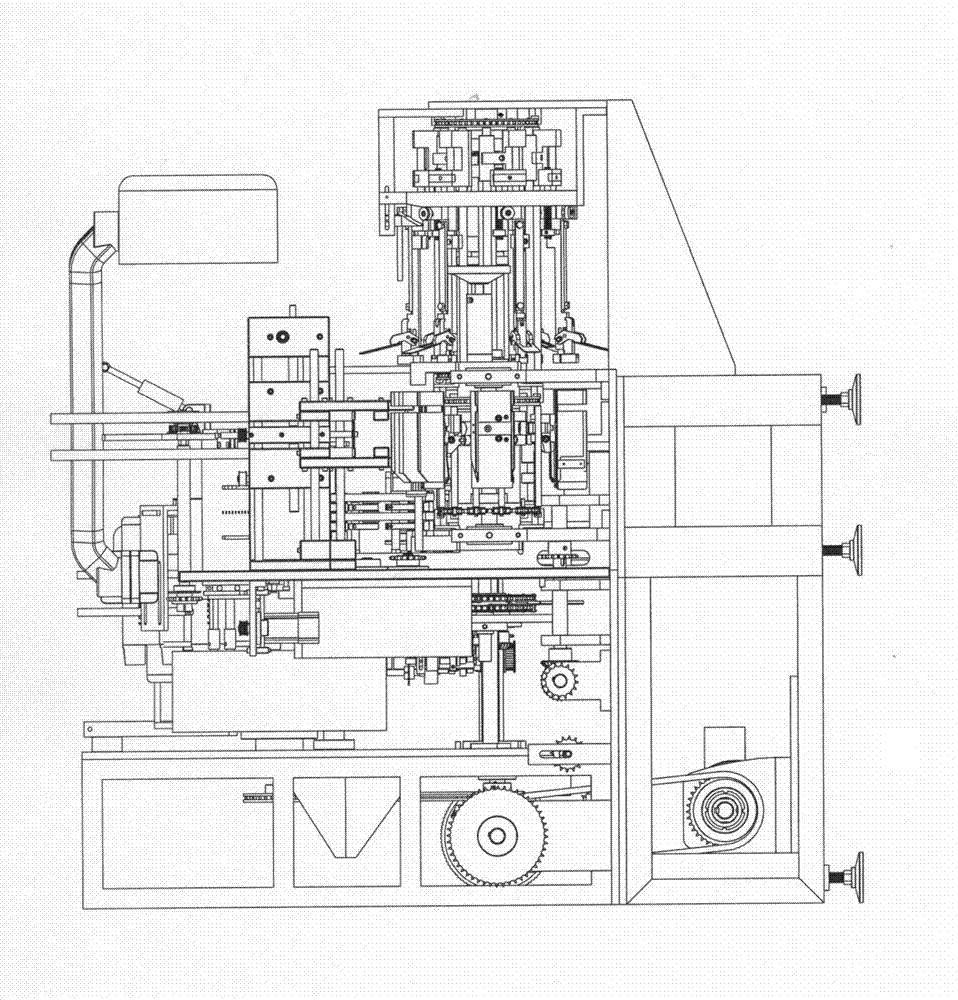

[0017] The accompanying drawings show the technical solution of the present invention and its embodiments, and the relevant details and working principles of the embodiments will be further described below in conjunction with the accompanying drawings. This kind of block-type material continuous high-speed cartoning machine, the whole machine includes a formed chain row type continuous plate holding device 13, a block conveying device, a carton forming device, a block entering box device and a carton conveying device, the block conveying device Set side by side with the carton conveying device, the carton forming device includes a carton adsorption device, the carton adsorption device includes a rotating turntable, and the turntable 30 is provided with four dry suction rods 31 with suction nozzles , the suction rod is arranged in equal parts around the turntable in the circumferential direction, and a carton material rack is arranged beside the turntable, and the material rack ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com