Electrolyzing water production machine

A technology of electrolytic water generator and electrolytic cell, which is applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of large volume and occupied space, and achieve small volume, Low power consumption, high efficiency to remove and kill germs quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to achieve the above object, the technical scheme realized is as follows:

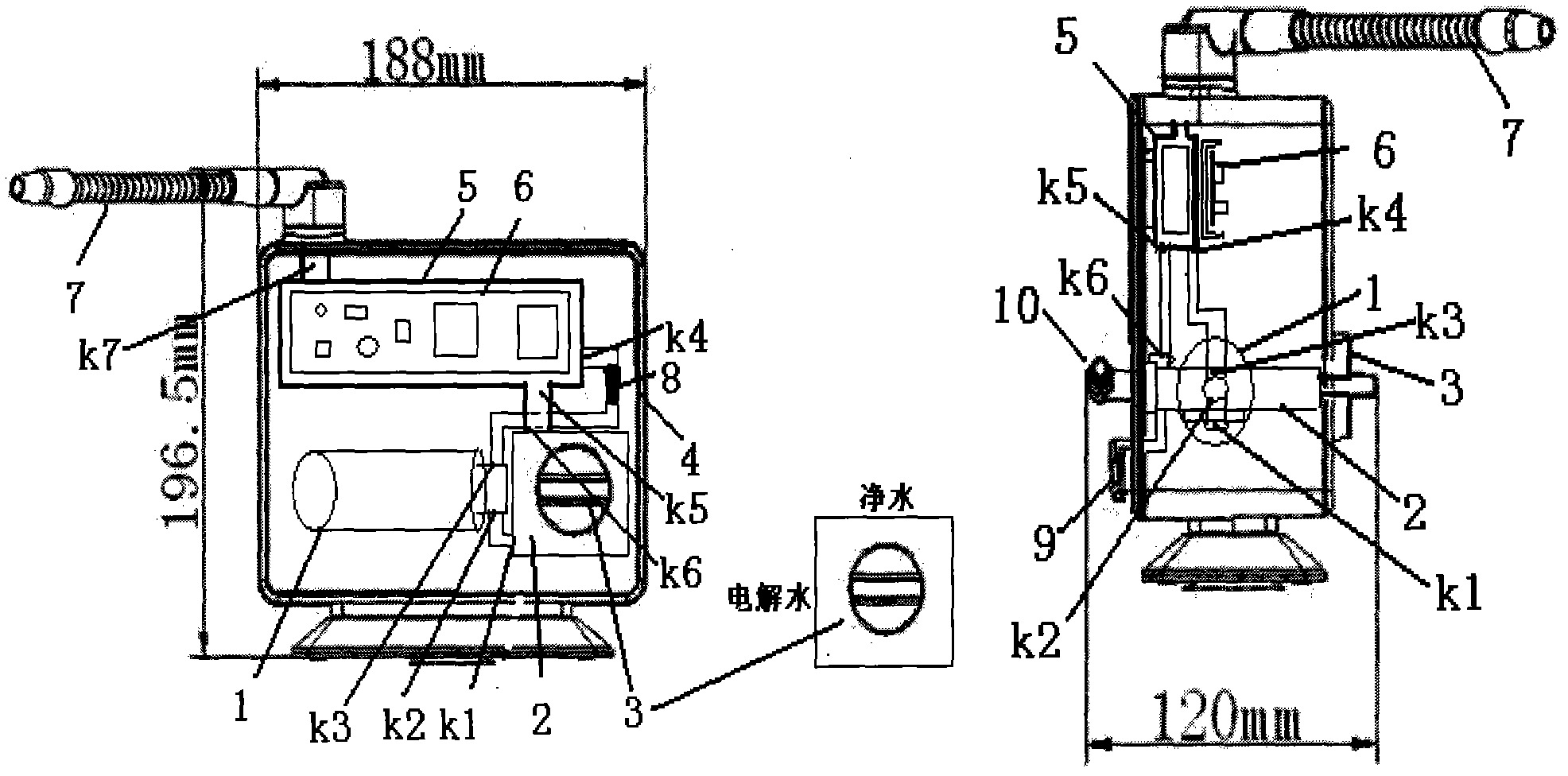

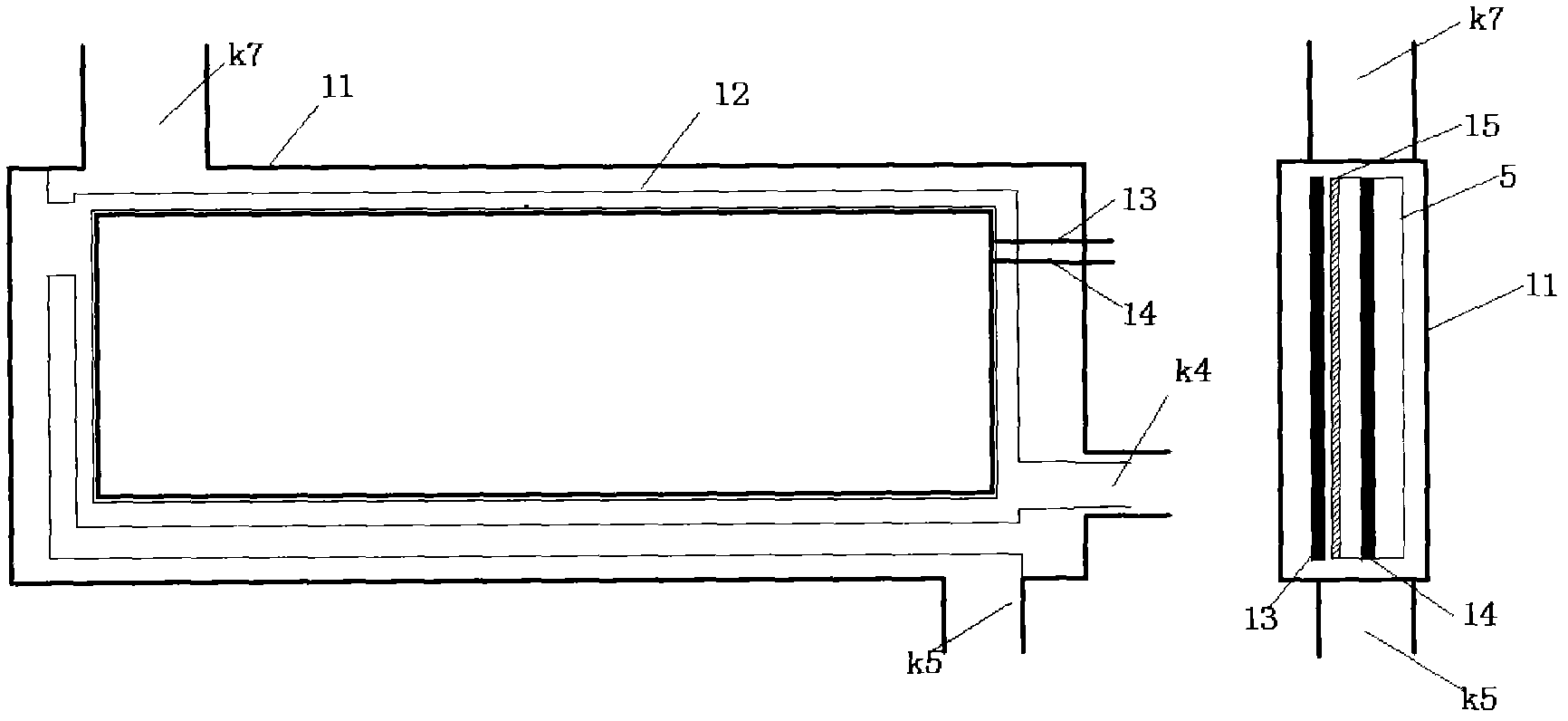

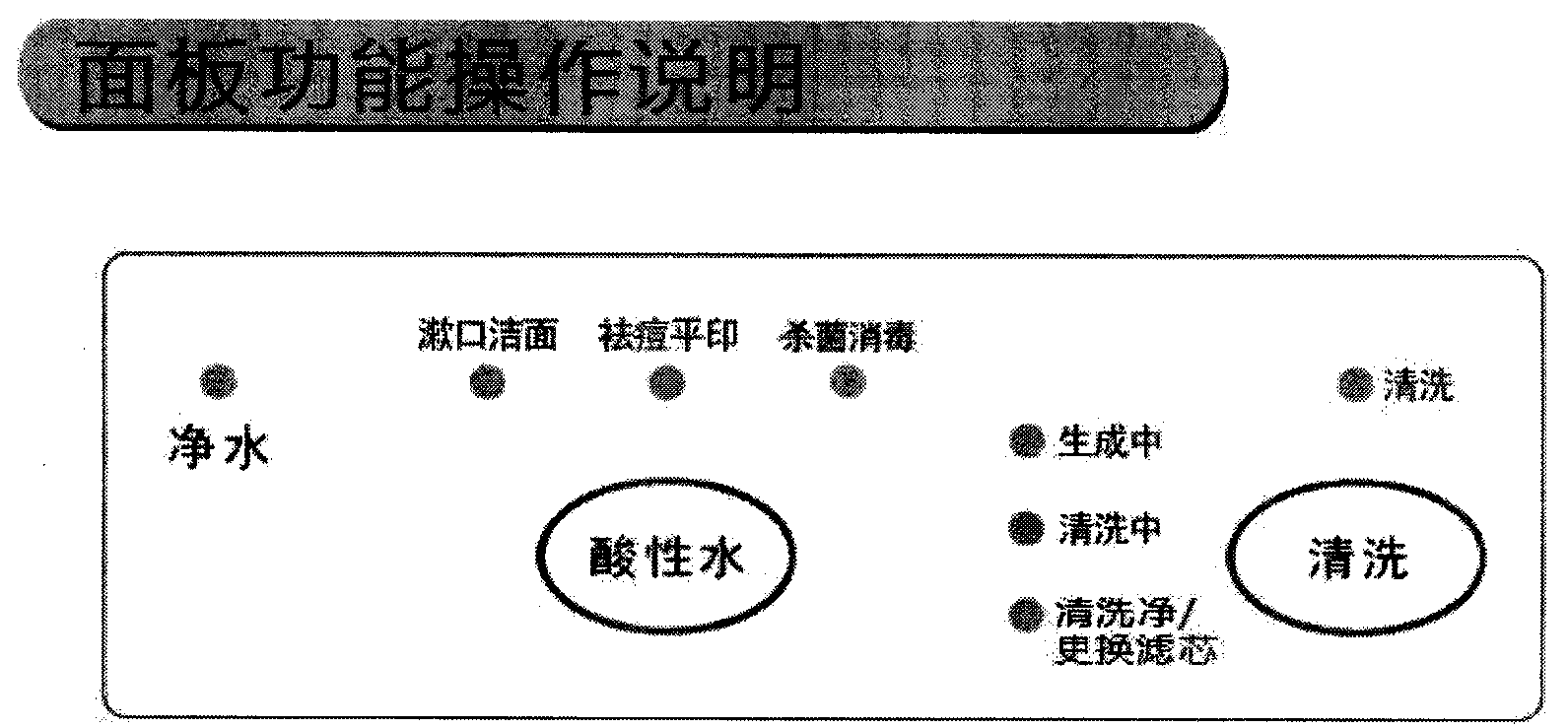

[0025] A low-power water-saving electrolytic water generator includes: filter element 1, flow controller 2, flow control knob 3, water machine casing 4, electrolytic tank 5, circuit control board 6, coil outlet pipe 7, Hall flow switch 8. Thin tube water outlet 9, water inlet 10, flow controller outlet K1, filter element water inlet K2, filter element water outlet K3, electrolytic cell water inlet K4, electrolytic cell alkaline water outlet K5, flow controller electrolytic cell thin tube Outlet pipe interface K6, electrolytic cell acidic water outlet K7. The electrolytic cell 5 is composed of the following components: a cell shell 11 , an inner tank shell 12 , an inner tank electrode plate 14 , an inner tank outer electrode plate 13 , and an ion diaphragm 15 .

[0026] Such as figure 1 , when electrolyzed water is used, the knob is turned to the position of electrolyzed water, the flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com