Forming device for tunnel center gutter and side ditches and forming process thereof

A technology for tunnel center and forming equipment, which is applied in tunnels, tunnel linings, mining equipment, etc. It can solve the problems of insufficient sealing of formwork, difficulty in controlling installation quality, and running molds, so as to improve pouring effect and quality, improve work efficiency, Avoid the effect of height drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

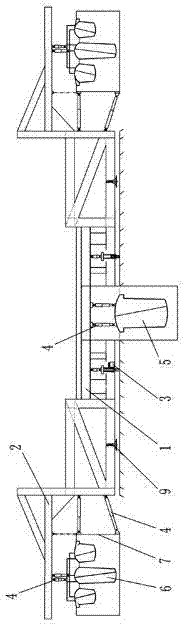

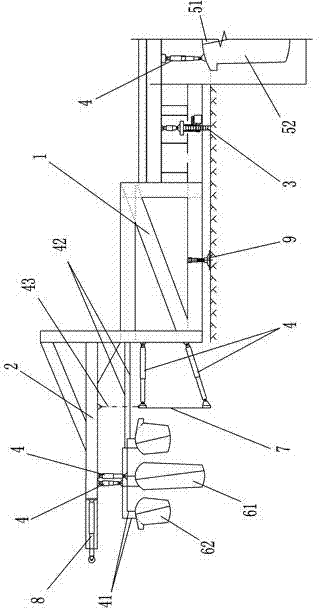

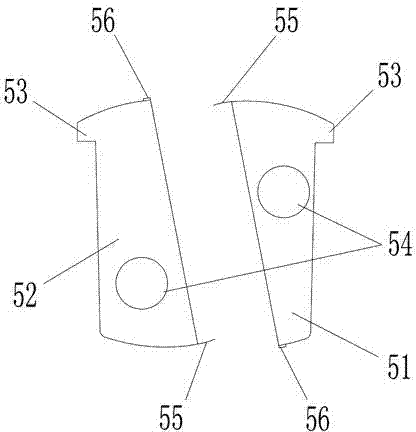

[0021] A kind of forming equipment for tunnel center gutter and side ditch, including main body stand 1, cantilever 2 provided on both sides of main body stand 1, and the loadable main body stand 1 arranged at the bottom of main body stand 1 for positioning and moving in the tunnel The traveling mechanism 3 of the main body platform 1 is equipped with a central gutter formwork 5 through a telescopic mechanism 4 under the middle part of the main body frame, and a side ditch formwork 6 is installed under the cantilevers 2 on both sides through a telescopic mechanism 4 respectively.

[0022] Such as figure 1 , 2 shown.

[0023] In the forming equipment for the tunnel center gutter and side ditch, the bottom of the main frame 1 is provided with height-adjustable leveling support feet 9 for adjusting the balance of both sides of the frame 1 . After the bench 1 has reached the pouring position, put down the leveling support legs, and adjust the length of the leveling support legs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com