Multi-runner aluminum flat pipe for heat radiation

An aluminum flat tube, multi-channel technology, applied in the field of heat exchangers, can solve problems such as poor corrosion resistance, and achieve the effects of improving structural strength, high heat exchange efficiency, and improving corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

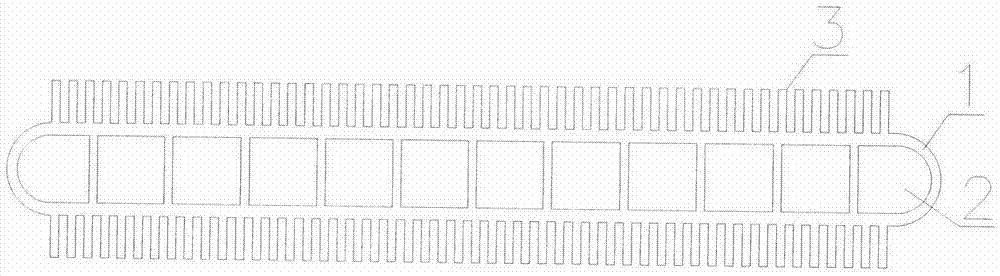

[0015] refer to figure 1 As shown, the schematic diagram of the structure of Embodiment 1 of the present invention: a multi-channel aluminum flat tube 1 for heat dissipation includes a number of flow channels 2 formed by the tube wall and a number of partitions, and there are many protrusions or grooves on the outside of the tube wall 3. The contact area between the aluminum flat tube 1 and the external medium is increased, so its heat transfer efficiency is higher than that of the bare tube, and there is no need to braze the aluminum fins, and the corrosion resistance is also improved. At the same time, the protrusion or the groove 3 forms a rib plate, which acts as a reinforcing rib, improves the structural strength of the pipe body, and increases the mechanical stability.

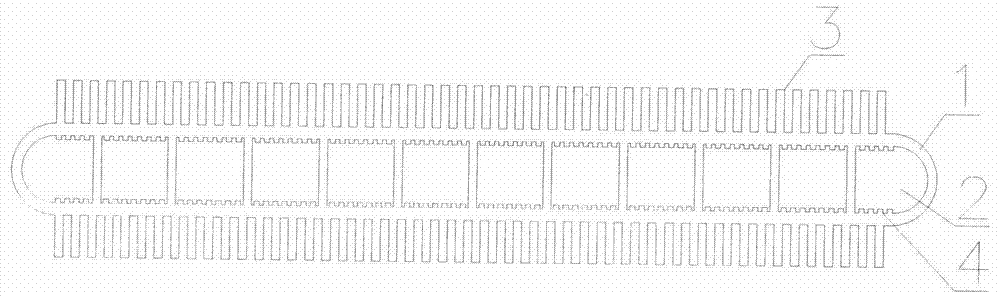

[0016] refer to figure 2 As shown, the structure diagram of Embodiment 2 of the present invention: a multi-channel aluminum flat tube 1 for heat dissipation, including a number of flow channels 2 forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com