Method for monitoring low-frequency vibration of wind power generation set

A technology for wind turbines and low-frequency vibration, which is applied in the control of wind turbines, wind turbines, and wind power generation, etc., can solve the problems of multiple vibration monitoring points for a single unit, increased maintenance workload of technicians, and large data processing workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

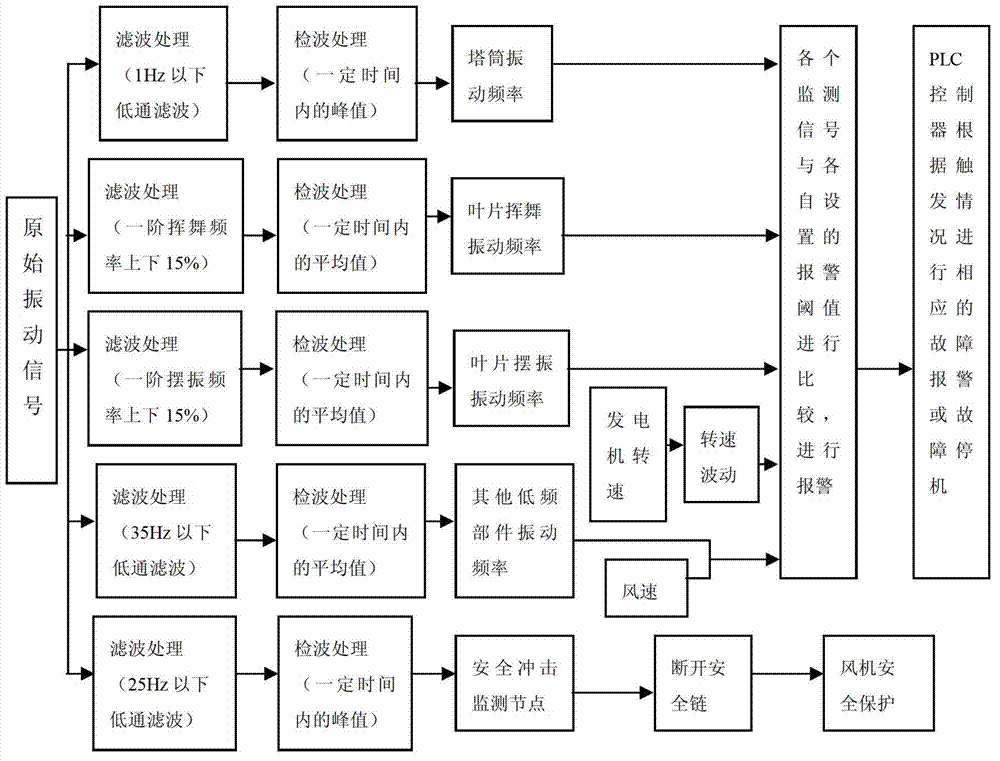

[0020] Such as figure 1 As shown,

[0021] The present invention mainly deals with the following low-frequency vibrations:

[0022] Tower vibration: In the low-frequency vibration of wind turbines, tower vibration is an important monitoring object. Generally, the first-order natural frequency of the tower is about 0.3~0.4HZ. It is usually considered as a three-blade wind turbine. The resonance force is the maximum harmonic component of 3 times the rotation speed. Therefore, when the natural frequency of the tower is close to an integer multiple of the rotation frequency within a certain range, a large dynamic stress will be generated, which makes the tower have the nature of resonance. Therefore, it is necessary for the unit to monitor the first-order natural frequency of the tower when the wind turbine is started and connected to the grid;

[0023] Blade vibration: The monitoring of blade vibration is mainly the aerodynamic force, gravity and centrifugal force on the blade, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com