Synchronous sampling device for liquid drops and dust in smoke gas

A synchronous sampling and droplet technology, applied in sampling devices and other directions, can solve the problems of hose blockage, difficult realization, desiccant replacement and inaccurate sampling, etc., to achieve simple structure, avoid blockage and damage to instruments, and prevent damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

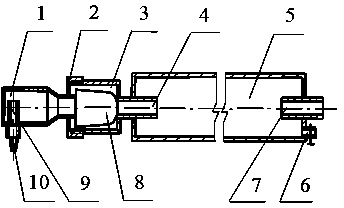

[0023] A simultaneous sampling device for liquid droplets and dust in flue gas. The simultaneous sampling device such as figure 1 Shown, includes impactor droplet trap, particulate trap, and sampling tube.

[0024] The impact droplet catcher consists of an impact tube 9 , a droplet catcher housing 1 and a sampling nozzle 10 . The outlet end of the impact tube 9 penetrates the large end near the droplet catcher housing 1, the impact tube 9 is fixed on the outer wall of the droplet catcher housing 1, and the center line of the impact tube 9 is aligned with the droplet catcher. The center lines of the device housing 1 are perpendicular to each other, and the length of the impact tube 9 penetrating the droplet collector housing 1 is (1.3~1.5) times the radius of the droplet collector housing 1, and the inlet of the impact tube 9 The sampling nozzle 10 is connected to the inlet end of the impingement tube 9 through threads.

[0025] The particle trap consists of a particle trap ...

Embodiment 2

[0031] A simultaneous sampling device for liquid droplets and dust in flue gas. Except following technical parameter, all the other are with embodiment 1:

[0032] In this embodiment: the pipe length of the impingement tube 9 penetrating the droplet catcher housing 1 is (1.5-1.7) times the radius of the droplet catcher casing 1; The diameter ratio of end and small end is (3~4): 1; The diameter ratio is 1: (3 ~ 4); the lengths of the left water retaining pipe 4 and the right water retaining pipe 7 in the sampling pipe 5 are respectively 4 ~ 5cm.

[0033] This specific embodiment realizes the synchronous sampling of liquid droplets and dust in the flue gas. When the liquid droplets contained in the flue gas pass through the impact droplet collector, they hit the wall of the device, thereby being captured and flowing along the wall of the device. Flow into the lower part of the droplet collector housing 1; at the same time, the dust contained in the flue gas is collected in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com