Method for determining technological parameters in flow industrial process

A technology of process parameters and process industry, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of ineffective control of product quality, difficult to adjust process parameters, and easy occurrence of waste products, etc., to achieve optimization. Determine the effect of convenience and speed, simple operation, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 Method for Determining Process Parameters Based on Data-Driven Process Industry

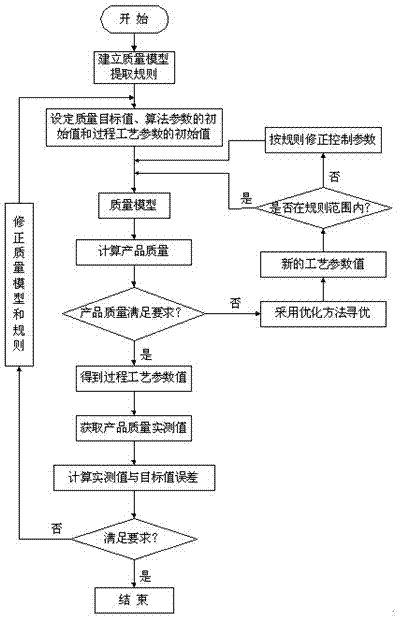

[0027] technology roadmap as figure 1 As shown, the specific steps are:

[0028] The first step is to establish a quality model extraction method: firstly, normalize the existing production data to eliminate the influence of different dimensions, use the data extracted in the production process to establish a quality model, and use the method of rule extraction to extract process parameters The rule knowledge between quality indicators and quality indicators forms a rule base;

[0029] The second step is to set the quality target value, the initial value of the algorithm parameter and the initial value of the process process parameter: when the process parameter is initialized, first find its corresponding rule according to the given quality target value, and then initialize the process parameter in the rule Within the scope of optimization, reduce the optimization space and sp...

Embodiment 2

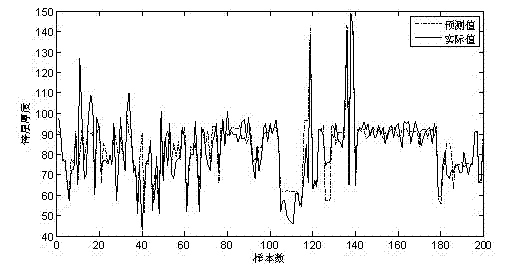

[0038] Embodiment 2 Simulation experiment

[0039] In order to verify the effectiveness of the method of the present invention, a simulation experiment is carried out on the method for optimizing and determining process parameters in the present invention.

[0040] The simulation experiment takes the hot-dip galvanizing production process of an iron and steel enterprise as an example, and optimizes the process parameters according to the given quality index.

[0041] Process parameters include: air knife pressure p , the distance from the air knife to the strip d and unit speed v , the target product quality is the zinc layer weight w .

[0042] In the production process, generally by adjusting p , d , v These three process parameters are used to control the weight of the zinc layer on the strip w .

[0043] When producing a specified zinc layer weight, these three parameters need to be adjusted at the same time. At present, it is mainly operated by manual experience,...

Embodiment 3

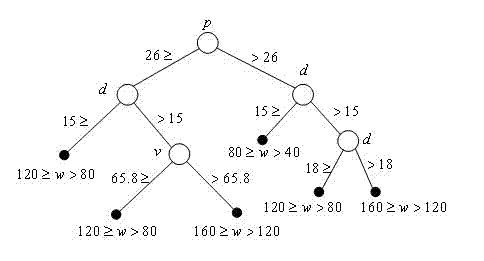

[0050] Example 3 Decision tree extraction rules

[0051] Similarly, using the same data, using the decision tree to extract rules, the remaining 200 sets of data are used to verify the model.

[0052] Here, the weight data of the zinc layer should be classified first, and according to the different requirements for the weight of the zinc layer, the weight of the zinc layer can be divided into three categories, that is, 115 w ≤146 (Class 1), 80 ≤ w w p , d , v as the leaf node of the tree.

[0053] image 3 For the obtained decision tree, the corresponding rules are:

[0054]

[0055] The rule accuracy reaches 94.34%.

[0056] To coat the strip surface with 60 g / m 2 When the weight of the zinc layer is determined, it can be found that the weight of the zinc layer corresponds to rule 4, that is, the value range of the process parameters is restricted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com