Optical film system optimization design method and product

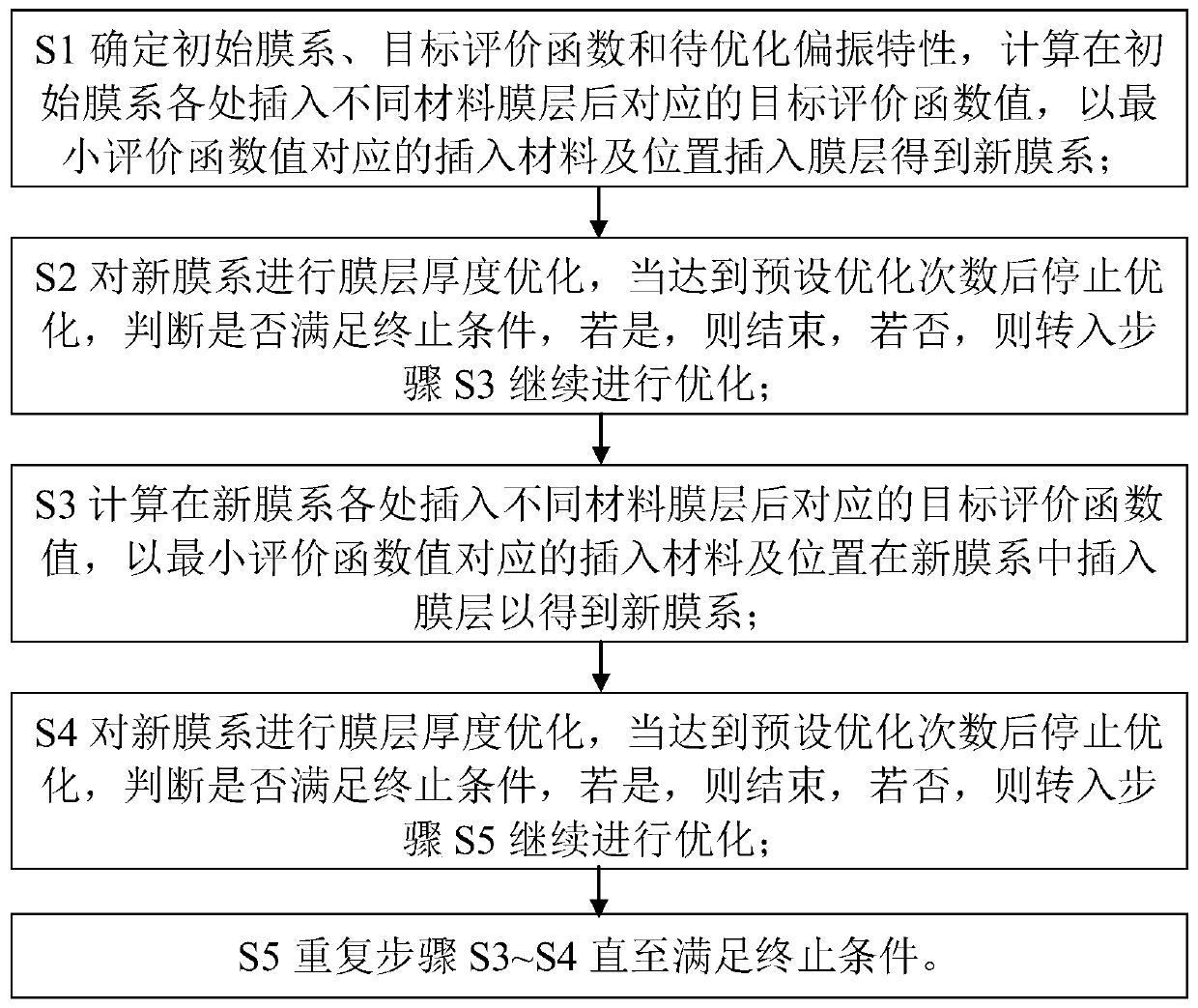

An optimized design, optical film technology, applied in optics, optical components, complex mathematical operations, etc., can solve problems such as unoptimizable information, few reports on depolarization beam splitters, and complex mathematical polarization calculation, and achieve fast optimization speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

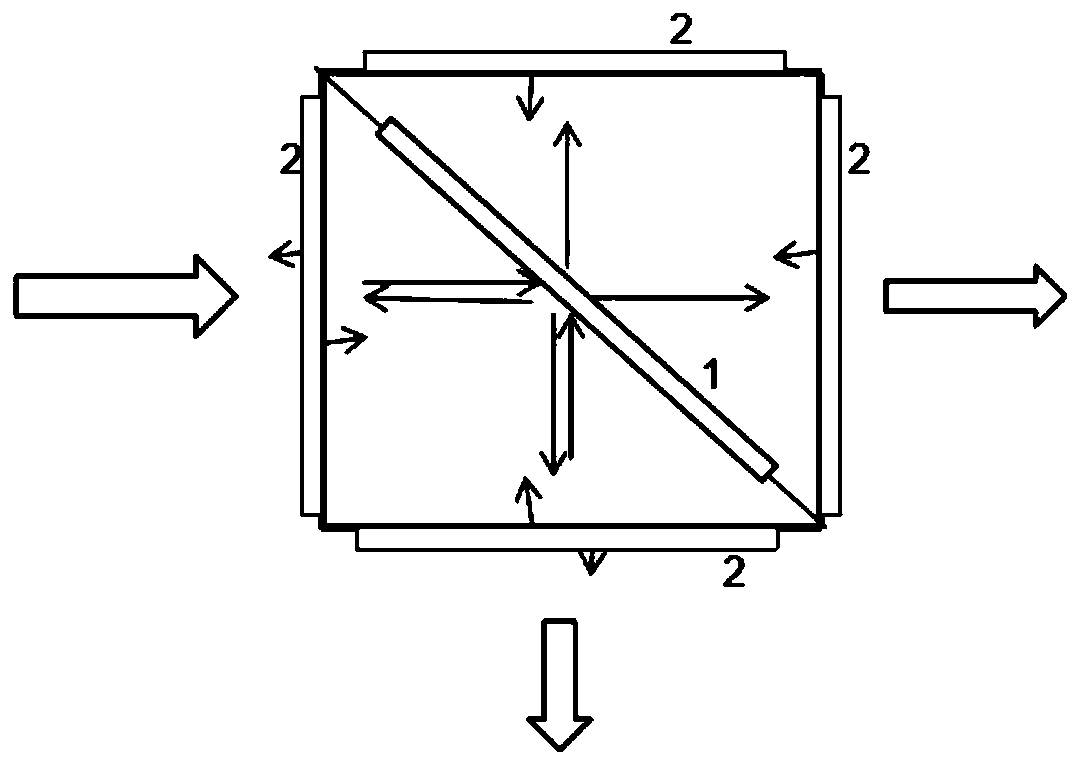

[0099] This embodiment relates to the design of the non-polarizing film system of the depolarized glued cubic beam splitter with wide band and wide acceptance angle. The structure of the beam splitter is as follows figure 2 As shown, the design of the non-polarizing film system of the beam splitter adopts a dielectric-metal scheme, and the materials used are all commonly used coating materials: TiO 2 , Al 2 o 3 , SiO 2 , Ag, specifically includes the following steps:

[0100] (1) Select material and design initial film system

[0101] Because the addition of a metal material film layer can flatten the polarization characteristic curve of a wide band, and it is easy to realize the design of wide acceptance angle change. Among them, Ag has the smallest polarization effect and better spectral neutrality in the visible light band, so the design material TiO 2 (marked as n 1 , whose optical constants refer to Figure 5 ), Al 2 o 3 (marked as n 2 , whose optical constants ...

Embodiment 2

[0120] This embodiment involves the design of the anti-reflection film system, which adopts an all-dielectric solution, and the materials used are all commonly used coating materials: TiO 2 , SiO 2 , MgF 2 , specifically including the following steps (basically consistent with the non-polarizing film design process):

[0121] (1) Select material and design initial film system

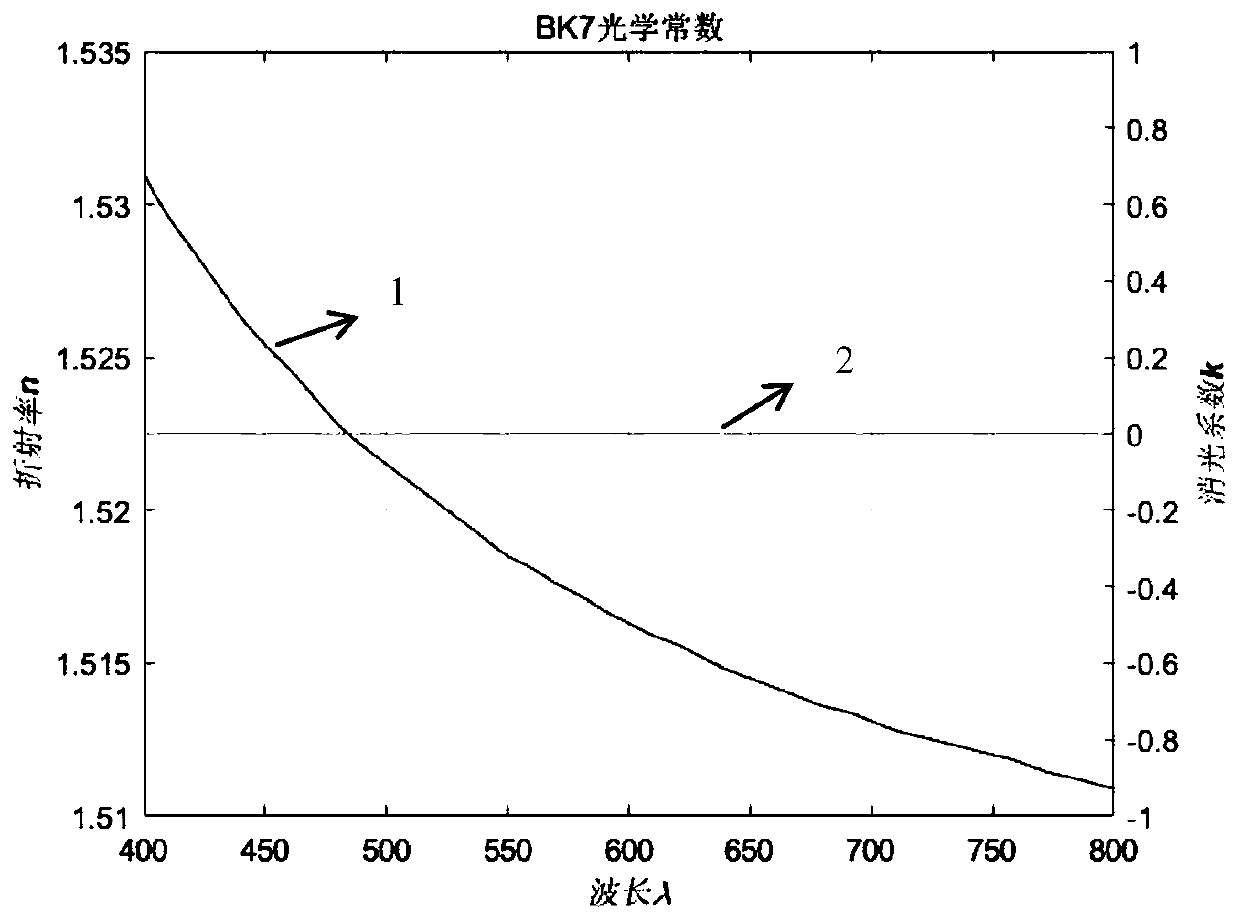

[0122] Select Design Material TiO 2 (marked as n 1 , whose optical constants refer to Figure 5 ), SiO 2 (marked as n 2 , whose optical constants refer to Figure 4 ), MgF 2 (marked as n 3 , whose optical constants refer to Figure 8 ), base BK7 (denoted as n 0 , whose optical constants refer to image 3 ), for the initial design, it is advisable to design a film system air|n with a two-layer film structure 1 ,n 3 n 0 , the physical thickness of the film layer is d n1 =20nm, d n3=20nm, the incident angle is 0°, and the incident medium is air (air);

[0123] (2) Setting design (optimiza...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com